Torsional vibration suppression device for rolling mill

A technology of suppressing device and rolling mill, applied in the direction of metal rolling, metal rolling, manufacturing tools, etc., can solve problems such as poor effect, and achieve the effect of horizontal vibration suppression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

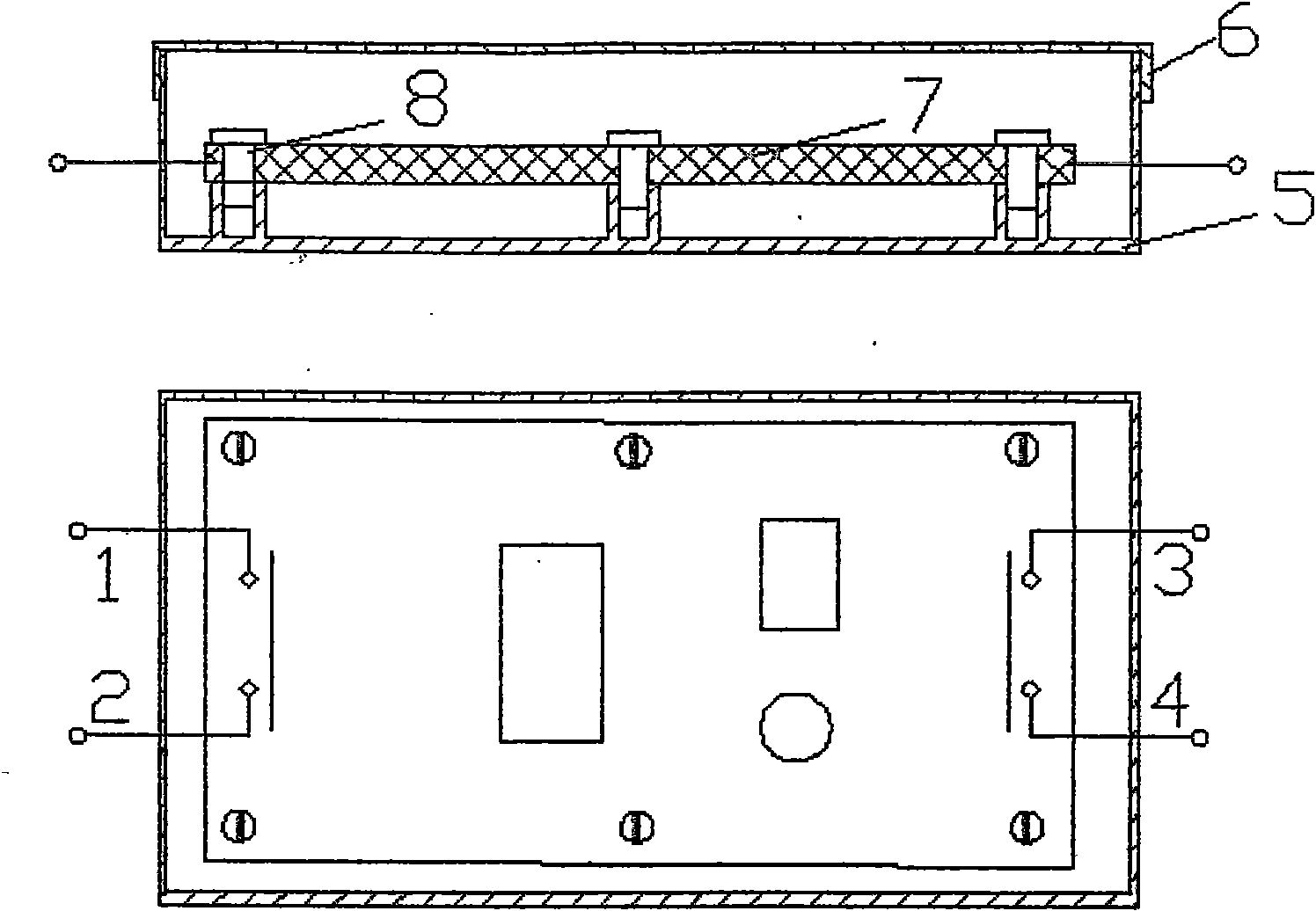

[0015] Such as figure 1 As shown, the vibration suppressor of the present invention is composed of input terminals 1 and 2, output terminals 3 and 4, casing 5, upper cover 6, printed circuit board 7 and screws 8. Connecting terminals 1 and 2 are input terminals of the printed circuit board 7 , connecting terminals 3 and 4 are output terminals of the printed circuit board, and the printed circuit board 7 is fixed on the casing 5 by screws 8 . Finally, the upper cover 6 is buckled on the shell 5 with an interference fit.

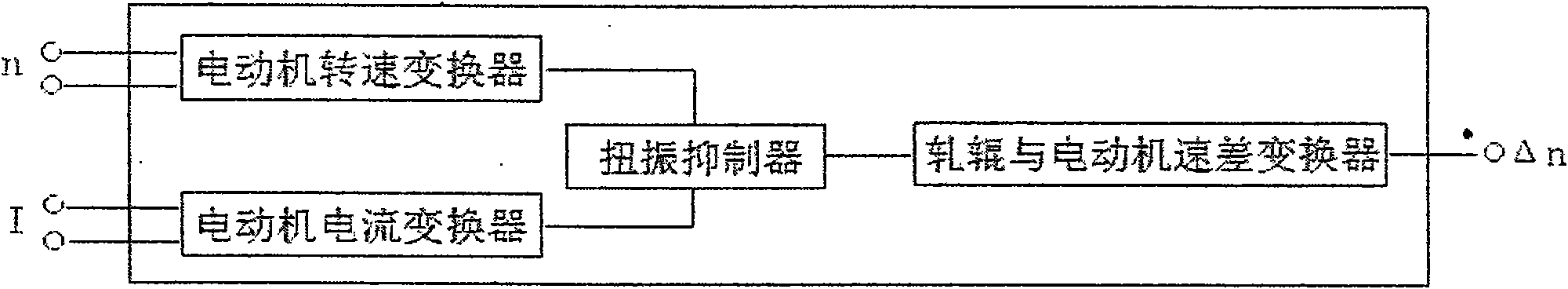

[0016] Such as figure 2 As shown, the present invention is composed of a motor speed converter, a motor current conversion, a torsional vibration suppressor and a roller and a motor speed difference converter. When the main transmission system of the continuous rolling mill generates torsional vibration, the torsional vibration suppressor receives the signals from the motor speed converter and the motor current converter, and the torsional vibration suppres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com