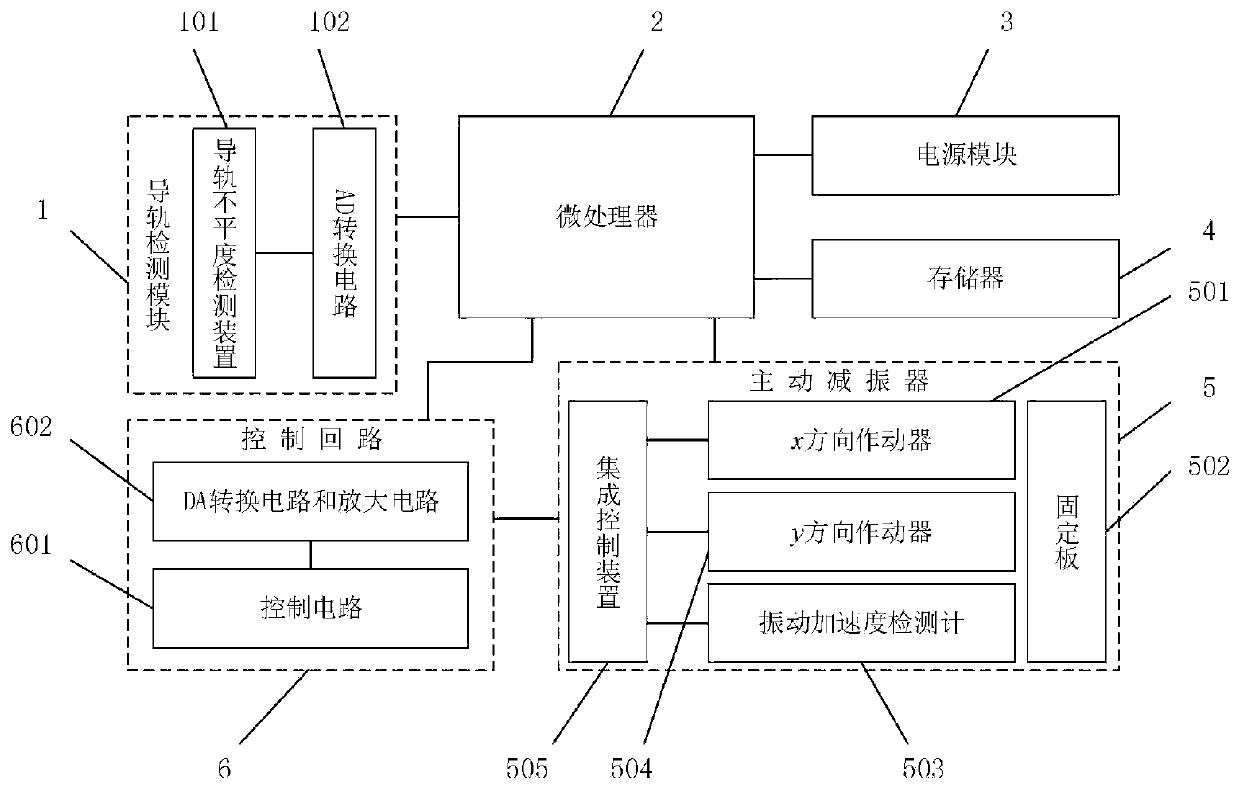

Vibration reduction system and control method for horizontal vibration of high-speed elevator car

A vibration damping system, high-speed elevator technology, applied in elevators, transportation and packaging in buildings, etc., can solve the problems of high failure rate, complex control algorithm, high energy consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

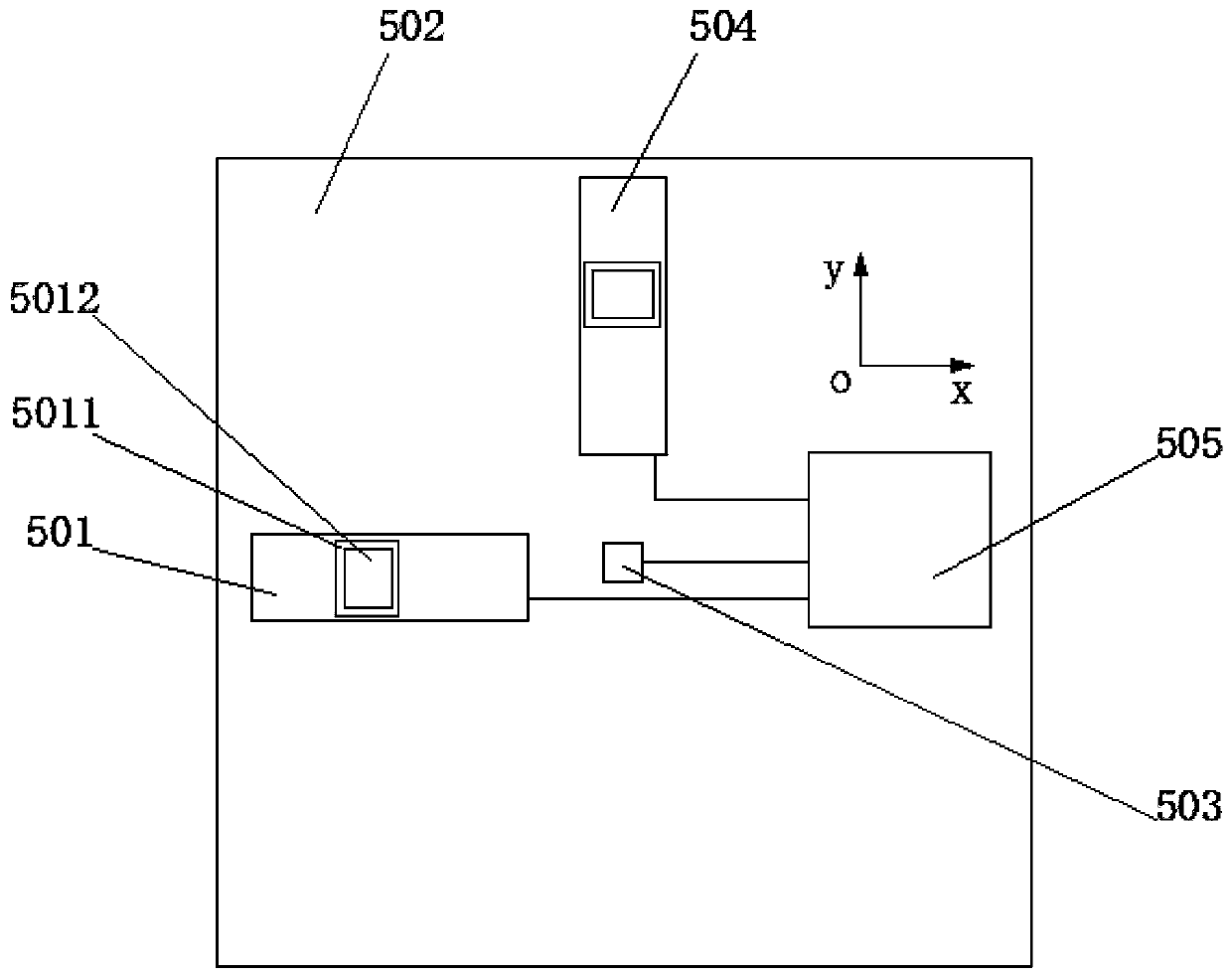

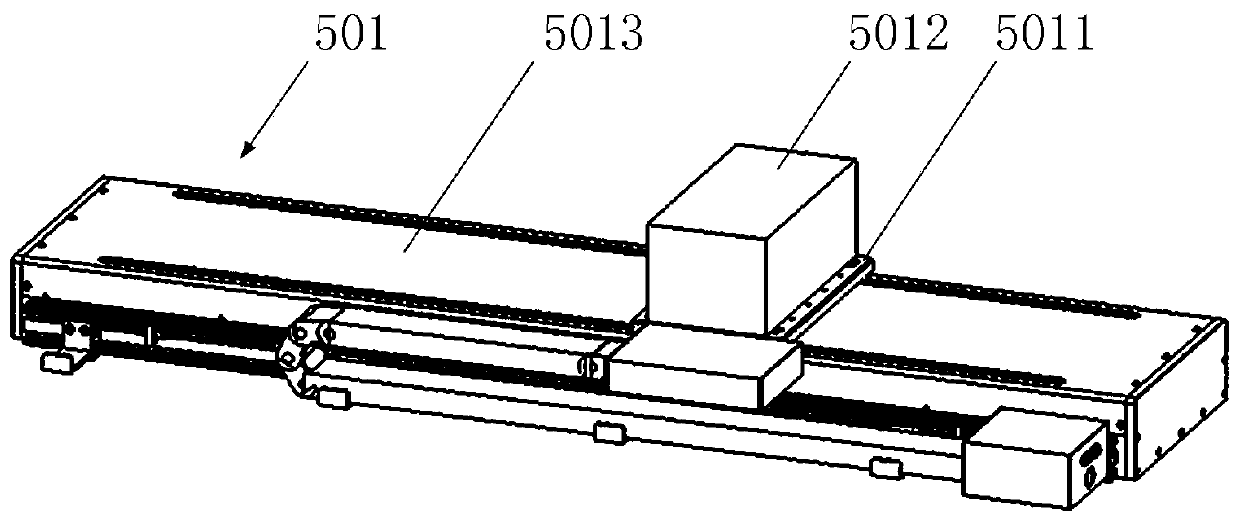

Embodiment Construction

[0084] In order to better understand the present invention, the specific embodiments of the present invention will be explained in detail below with reference to the accompanying drawings. Take the 4m / s high-speed elevator as an example to verify the feasibility and effectiveness of the high-speed elevator active shock absorber 5 intelligent control algorithm proposed in this research. The parameters are shown in the following table.

[0085] Table 1 High-speed elevator car system parameters

[0086]

[0087] The BP neural network PID controller adopts the linear prediction model to control the acceleration of the center position of the car bottom. The structure of the neural network (NN) is 3-3-3, the learning rate η = 0.3, the inertia coefficient α = 0.3, The initial value of the weighting coefficient is a random number in the interval [-0.5,0.5], and the sampling period Ts=0.05s.

[0088] X-direction horizontal vibration simulation results

[0089] The PID control algorithm based ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com