Method for extracting boron from magnesium-containing saline lake bittern

An extraction and magnesium salt technology, applied in the direction of boron/boride, etc., can solve the problems of economic inapplicability, and achieve the effect of reducing theoretical series, less consumption, and wide application prospect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

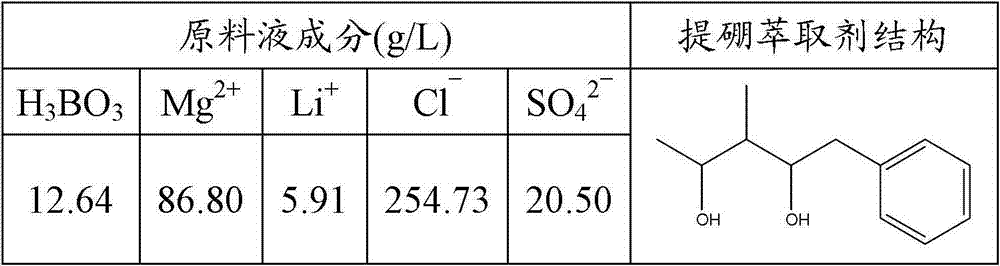

Embodiment 1

[0032] The magnesium-containing salt lake old brine after acidification and potassium extraction of Chaerhan Salt Lake brine in Qaidam Basin, Qinghai is used as the raw material solution, which contains 12.64g / L boric acid and 86.80g / L magnesium ions, and the pH of the raw material solution is 1.3. Using sulfonated kerosene as diluent, 1-benzyl-2-methyl-1,3-butanediol as boron extractant, and the mixed solution composed of boron extractant and diluent as extraction organic phase, extraction The concentration of the boron extraction agent in the organic phase is 0.2mol / L, the flow ratio of the extracted organic phase to the raw material liquid is 1, and 3 stages of countercurrent extraction are carried out at 25°C, and an organic extract containing boric acid is obtained in the first stage, and finally The raffinate aqueous phase is obtained in the first stage, and the extract phase containing boric acid is collected for multistage countercurrent back extraction. After extracti...

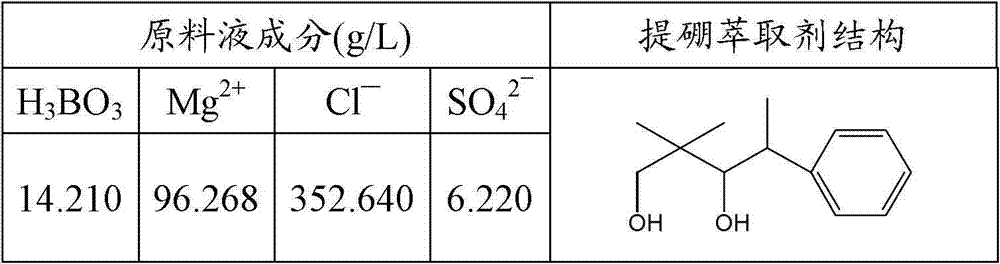

Embodiment 2

[0037] The magnesium-containing salt lake old brine after acidification and potassium extraction of the Chaerhan Salt Lake brine in the Qaidam Basin in Qinghai is used as the raw material solution, which contains 14.210g / L boric acid and 96.268g / L magnesium ions, and the pH of the raw material solution is 2. Alcohol is used as a diluent, 2,2-dimethyl-4-phenyl-1,3-pentanediol is used as a boron extraction agent, and a mixed solution composed of a boron extraction agent and a diluent is used as an extraction organic phase, and the extraction The concentration of the boron extraction agent in the organic phase is 0.4mol / L, the flow ratio of the extracted organic phase to the raw material liquid is 0.5, and 6 stages of countercurrent extraction are carried out at 20°C, and an organic extract containing boric acid is obtained in the first stage. The raffinate aqueous phase is obtained in the first stage, and the extract phase containing boric acid is collected for multistage counter...

Embodiment 3

[0042] The magnesium-containing salt lake old brine after potassium extraction from the Chaerhan Salt Lake brine in the Qaidam Basin of Qinghai is used as a raw material solution, with a pH of 5.5, containing 1.144g / L boric acid and 100g / L magnesium ions, using toluene as a diluent, and using 2 , 3-dimethyl-4-phenyl-1,3-pentanediol is the boron extraction agent, the mixed solution composed of boron extraction agent and diluent is used as the extraction organic phase, and the boron extraction agent in the organic phase is extracted The concentration is 0.5mol / L, the flow ratio of the extracted organic phase to the raw material liquid is 1, 5 stages of countercurrent extraction are carried out at 20°C, the organic extract phase containing boric acid is obtained in the first stage, and the raffinate aqueous phase is obtained in the last stage , after collecting the extract phase containing boric acid, carry out multi-stage countercurrent back extraction. After extraction, the con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| extraction efficiency | aaaaa | aaaaa |

| extraction efficiency | aaaaa | aaaaa |

| extraction efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com