Steel plate built-in eccentric support type steel plate shear wall

A steel plate shear wall and eccentric support technology, applied in the direction of walls, building components, earthquake resistance, etc., can solve the problems of floor damage, reduce steel consumption, structural rigidity and energy dissipation capacity, reduce damage, improve Ability to dissipate seismic energy, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the drawings.

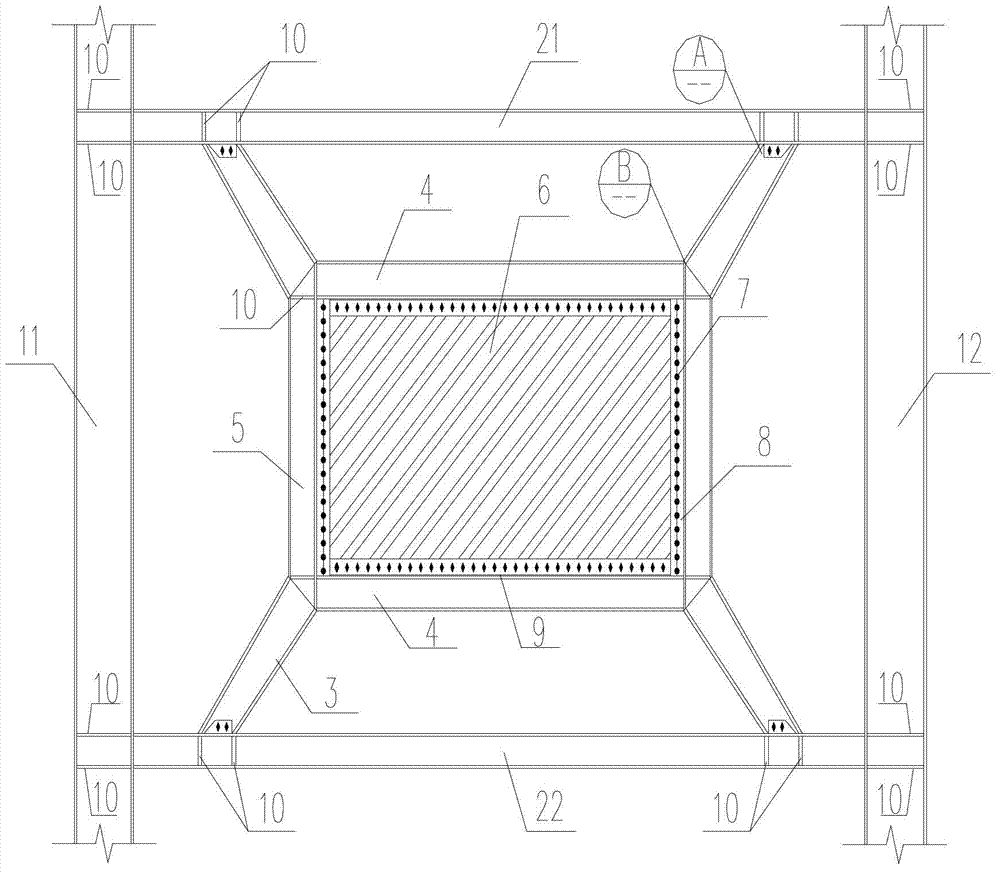

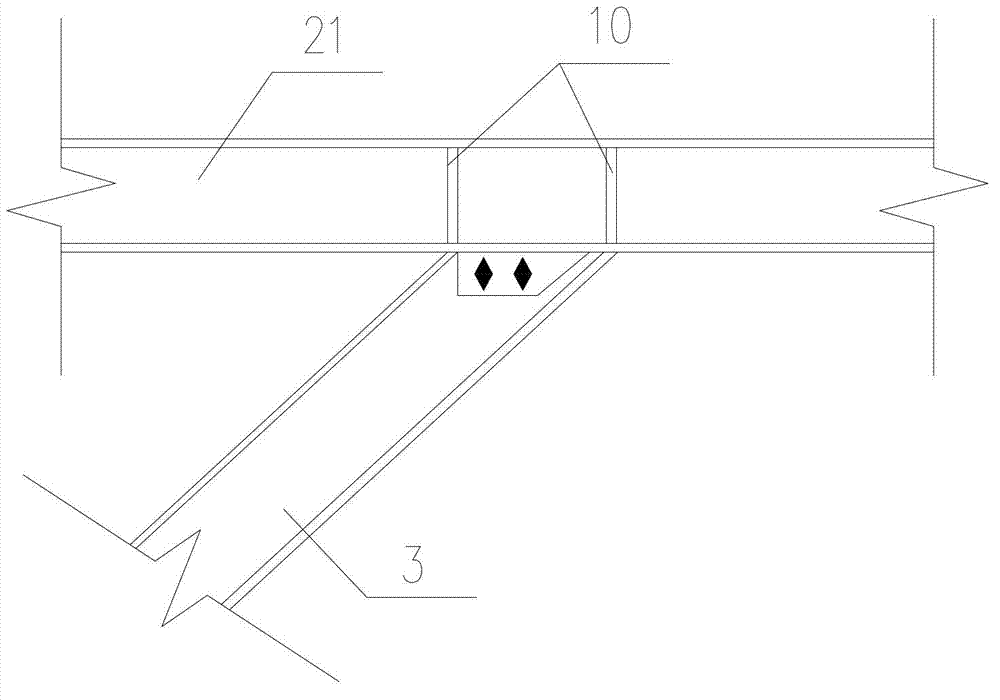

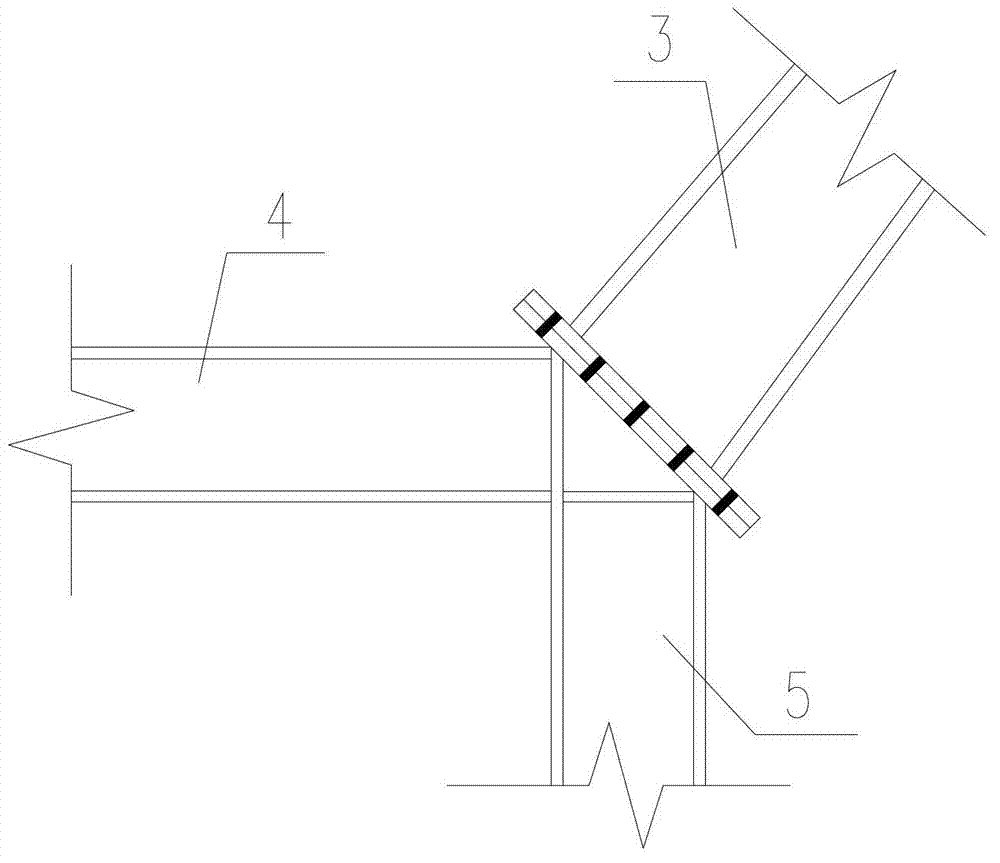

[0023] Such as figure 1 As shown, the present invention is an eccentrically supported steel plate shear wall with built-in steel plates, which includes a rectangular frame formed by connecting left frame columns 11, upper frame beams 21, right frame columns 12 and lower frame beams 22 in sequence. Frame column stiffeners 10 are provided on the frame column 11 and the right frame column 12 at the position equivalent to the beam-column connection. The thickness of the frame column stiffener 10 should be greater than or equal to the flange thickness of the upper frame beam 21 and the lower frame beam 22 to Improve the overall stability of the framework. In the middle of the rectangular frame, a rectangular inner-filled steel plate 6 is connected through an inclined support 3, and the inner-filled steel plate 6 is located at the center of the rectangular frame.

[0024] The upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com