Well control and wellhead equipment pressure testing device

A kind of equipment and pressure testing technology, which is applied in the direction of wellbore/well components, earthwork drilling, construction, etc., can solve the problems of increased production cost, influence on pressure maintenance and stability, and complicated flow path, so as to reduce processing and pressure starting Fast, less leaky effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

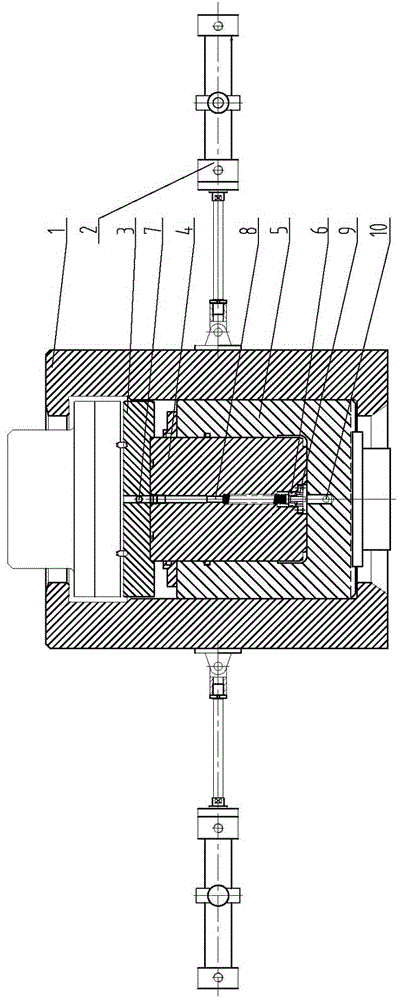

[0014] Description with reference to the accompanying drawings.

[0015] The high-pressure cylinder barrel 5 and the plunger 4 of the embodiment in the figure form a sealed cylinder. The high-pressure cylinder 5 is a fixed part of the sealed cylinder, which is fixedly installed on the base of the device; the plunger 4 is a moving part of the sealed cylinder. The blind flange 3 is detachably sealed and connected to the upper end surface of the plunger 4. Once the sealing groove on the blind flange 3 is damaged, only the blind flange 3 can be replaced to reduce the maintenance cost. The sealing groove on the upper end surface of the blind flange corresponds to the sealing groove on the bottom surface of the well control and wellhead equipment flange, and the sealing ring in the sealing groove seals and combines the blind flange 3 with the well control and wellhead equipment. The left and right half-open clamps 1 of the present embodiment are respectively hinged with a cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com