Conjugated bi-pass lighting confocal microscopic device of fluorescent reflecting mirror

A fluorescent mirror and confocal microscopy technology, applied in the direction of optical devices, measuring devices, instruments, etc., can solve the problems of reducing signal-to-noise ratio, improving axial resolution, and difficult numerical aperture, so as to improve point scanning resolution, Effect of overcoming interference disturbance and improving resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

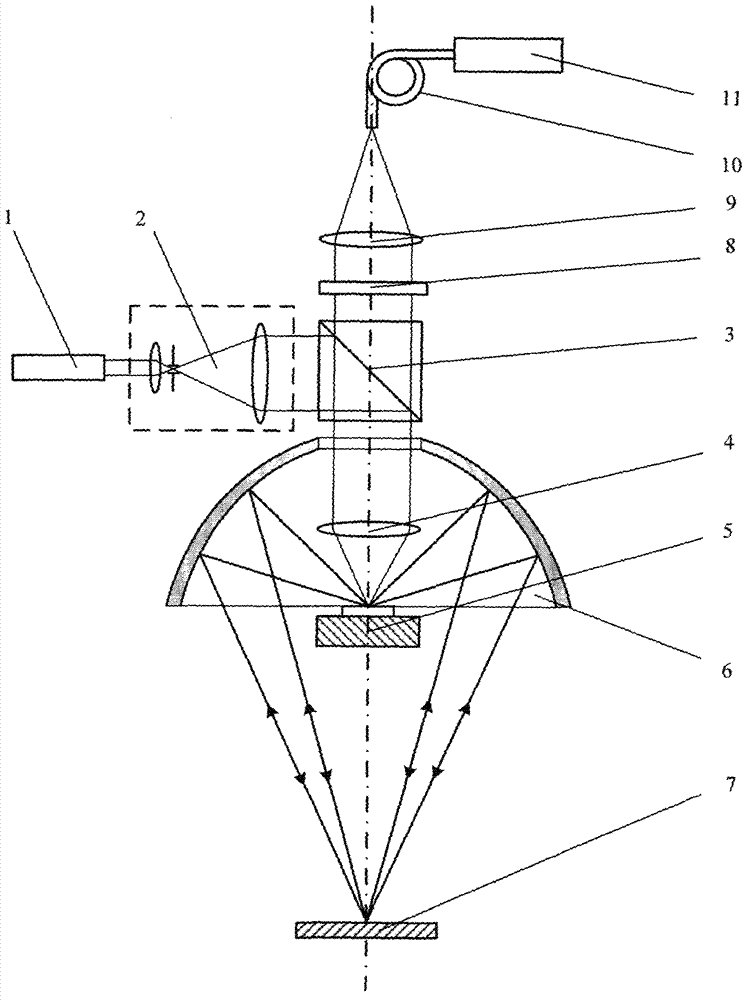

[0021] Fluorescent mirror conjugate double-pass illumination confocal microscope device includes: laser 1, collimator beam expander 2, beam splitter 3, focusing objective lens 4, three-dimensional micro-displacement stage 5, narrow-band filter 8, collecting objective lens 9, and conducting optical fiber 10. Photodetector 11; wherein, a collimating beam expander 2 and a beam splitter 3 are sequentially arranged on the direct optical path of the laser 1, a focusing objective lens 4 and a three-dimensional micro-displacement stage 5 are arranged on the reflected optical path of the beam splitter 3, and narrow-band filtering Sheet 8 and collecting objective lens 9 are configured on the transmission light path of beam splitter 3, and conduction optical fiber 10 conducts the light collected by objective lens 9 to photodetector 11, and an ellipsoid mirror 6 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com