Sodium hypochlorite manufacturing electrolytic cell

A sodium hypochlorite and electrolytic cell technology, applied in the field of electrolytic cells, can solve problems such as hindering the electrolytic reaction of salt water, corrosion or leakage, and unsmooth flow of salt water, and achieve the effects of easy disassembly and assembly, prevention of explosion, excellent electrolysis efficiency and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

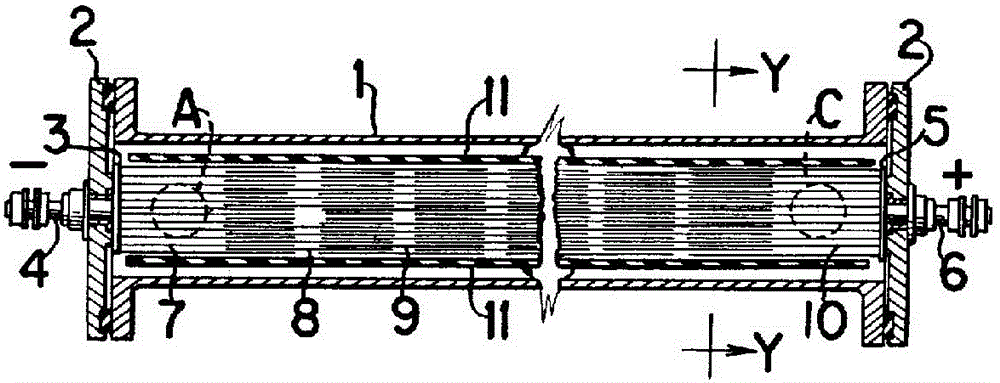

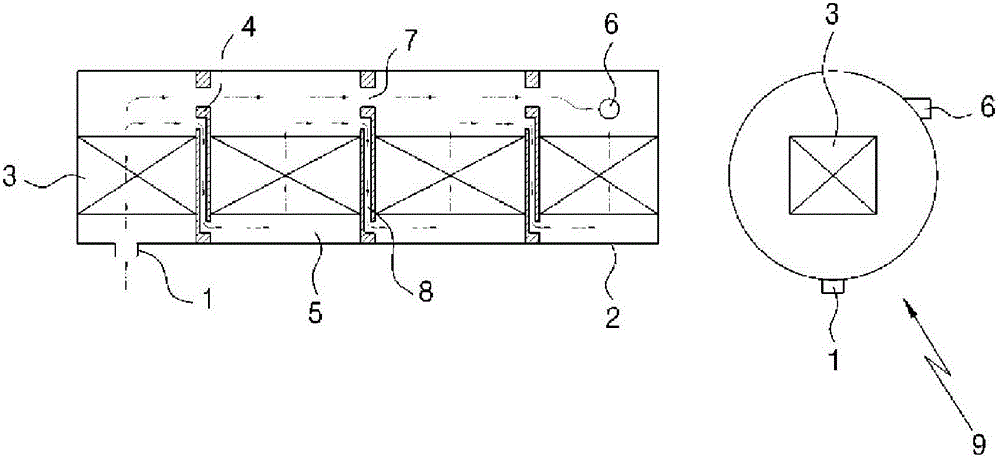

[0030] The present invention will be described in detail using the above drawings as follows. However, although the components required by the present invention, specific descriptions are omitted for components that belong to the general technology or are the same as the prior art. And regardless of what has been introduced in the prior patent literature figure 1 and figure 2 , in the present invention, new names and drawing symbols are assigned to each component factor.

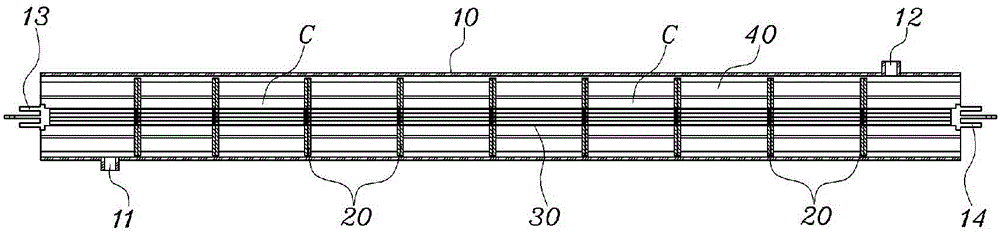

[0031] According to the electrolytic cell for producing sodium hypochlorite of the present invention is as image 3 and Figure 4 , consists of a hollow shell 10 , an isolation plate 20 and an electrode plate 30 installed inside the above-mentioned shell 10 , and an isolation plate fixing rod 40 . Among the above components, except for the electrode plate 30, the case 10, the separator 20 and the fixing rod 40 of the separator are made of non-conductive materials, polyvinyl chloride (PVC) or glass reinf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com