Drying method and drying device of anionic surfactant

A technology of surfactant and drying method, applied in the field of drying of anionic surfactants, powdery or needle-like finished products, can solve the problems such as no reports on drying method and equipment of ammonium dodecyl sulfate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

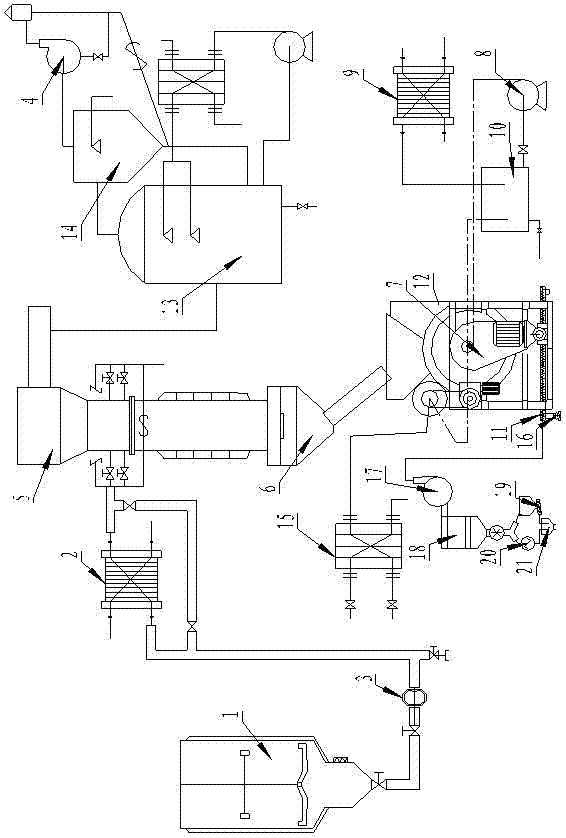

Image

Examples

Embodiment 1

[0034] The dodecyl ammonium sulfate slurry, with a temperature of about 45°C and a solid content of about 60%, is preheated to 60°C through the preheating heat exchanger 2, and pumped to the top of the wiped film evaporator 5 through the delivery pump 3 The temperature of the first layer of wiped film evaporator 5 is 110°C, the temperature of the second layer is 105°C, the temperature of the third layer is 100°C, and the temperature of the fourth layer is 95°C. The temperature of the two rollers, the inner surface of the large roller is continuously supplied with cooling medium, the temperature is 20°C, the inner surface of the small roller is continuously supplied with hot water, the temperature is controlled at 80°C, the flakes are sent to the centrifugal mill 20 to produce powder twelve Alkyl ammonium sulfate, the moisture content of the finished product is 5%.

Embodiment 2

[0036] The dodecyl ammonium sulfate slurry, with a temperature of about 45°C and a solid content of about 65%, is preheated to 70°C through the preheating heat exchanger 2, and pumped to the top of the wiped film evaporator 5 through the delivery pump 3 , the temperature of the first layer of wiped film evaporator 5 is 105°C, the temperature of the second layer is 100°C, the temperature of the third layer is 100°C, and the temperature of the fourth layer is 95°C. The temperature of the two rollers, the inner surface of the large roller is continuously supplied with cooling medium, the temperature is 20°C, the inner surface of the small roller is continuously supplied with hot water, the temperature is controlled at 100°C, the flakes are sent to the centrifugal mill 20 to produce powder twelve Alkyl ammonium sulfate, the moisture content of the finished product is 4.2%.

Embodiment 3

[0038] The dodecyl ammonium sulfate slurry, with a temperature of about 45°C and a solid content of about 70%, is preheated to 75°C through the preheating heat exchanger 2, and pumped to the top of the wiped film evaporator 5 through the delivery pump 3 , the temperature of the first layer of wiped film evaporator 5 is 110°C, the temperature of the second layer is 105°C, the temperature of the third layer is 100°C, and the temperature of the fourth layer is 95°C. The temperature of the two rollers, the inner surface of the large roller is continuously supplied with cooling medium, the temperature is 20°C, the inner surface of the small roller is continuously supplied with hot water, the temperature is controlled at 75°C, the flakes are sent to the centrifugal mill 20 to produce powder twelve Alkyl ammonium sulfate, the moisture content of the finished product is 3.8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com