Combined fertilizer and preparation method thereof

A technology of combining fertilizers and chemical fertilizers, applied in fertilizer mixtures, fertilization devices, applications, etc., can solve difficult problems, achieve good fertilizer efficiency, improve yield and quality, and promote crop production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

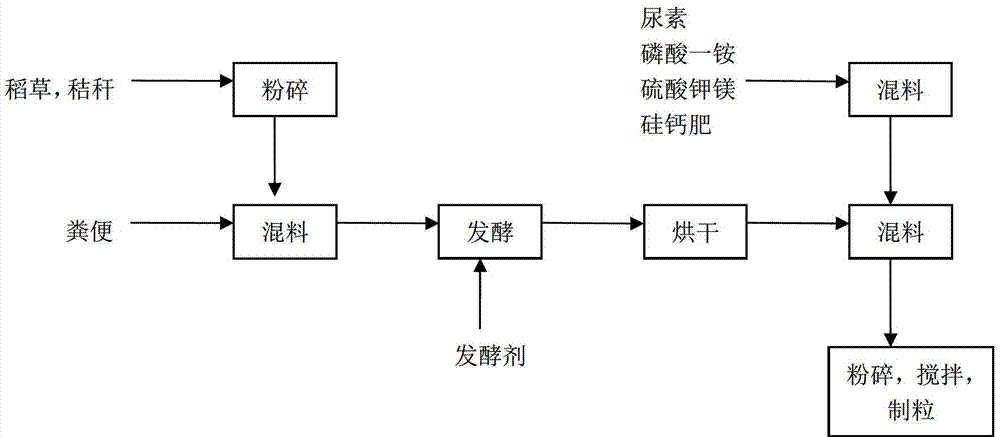

Method used

Image

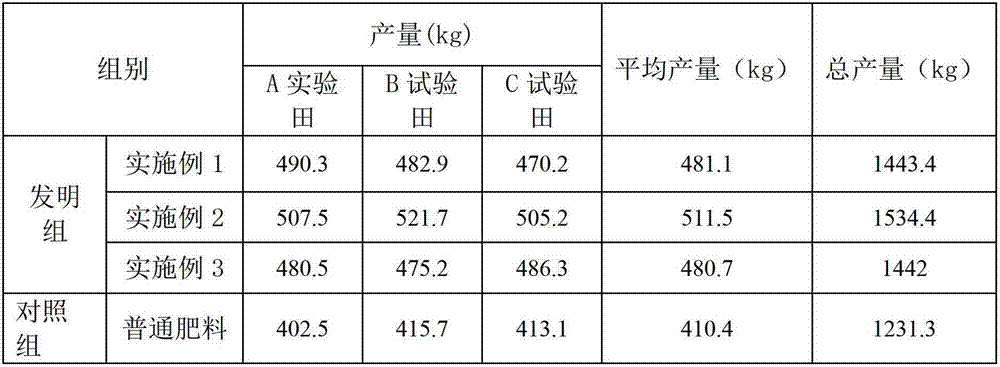

Examples

Embodiment 1

[0040] (1) Take straw, mix and crush the straw to obtain a mixture A20kg;

[0041] (2) Add animal manure 40kg in the mixture A in step (1), mix and stir to obtain mixture B60kg;

[0042] (3) Ferment the stirred mixture B at 50 degrees Celsius and decompose. The present invention adopts strip-stack fermentation, and the starter used contains yeast, actinomycetes, bacteria, filamentous fungi and other microbial flora, the amount of starter is about 0.1kg, and the fermentation period is 7 days. It is an exothermic process. Therefore, in order to prevent the activity of the starter from being affected by the high temperature of the raw materials, a compost turner is used to regularly turn the compost, which can not only control the temperature within the required range, but also mix all kinds of raw materials evenly.

[0043] (4) Dry the mixture B through fermentation and decomposing in step (3), pulverize, and obtain organic matter as 50kg. After the fermentation is completed, ...

Embodiment 2

[0048] (1) Take straw, mix and crush the straw to obtain a mixture A30kg;

[0049] (2) Add animal excrement 43kg in the mixture A in step (1), mix and stir to obtain mixture B73kg;

[0050] (3) Ferment the stirred mixture B at 60 degrees Celsius and decompose. The process is the same as described in Example 1.

[0051] (4) The fermented and decomposed mixture B in step (3) is dried and pulverized to obtain 63 kg of organic matter, and about 10 kg of moisture is removed during the drying process. After the drying is completed, the semi-finished raw materials are crushed to prevent agglomeration and affect the quality of the organic fertilizer.

[0052] (5) Take 8kg of urea, 7kg of monoammonium phosphate, 14kg of potassium magnesium sulfate, and 8kg of silicon-calcium fertilizer to make a total of 37kg of chemical fertilizers;

[0053] 6. Add the chemical fertilizer prepared in the step 5 to the organic fertilizer, mix and stir to obtain a total of 100kg of mixture C;

[005...

Embodiment 3

[0056] (1) Take straw, mix and crush the straw to obtain a mixture A30kg;

[0057] (2) Add animal excrement 55kg in the mixture A in step (1), mix and stir to obtain mixture B85kg;

[0058] (3) Ferment the stirred mixture B at 60 degrees Celsius and decompose. The process is the same as described in Example 1.

[0059] (4) Dry the fermented and decomposed mixture B in step (3), pulverize, and obtain 75 kg of organic matter, and about 10 kg of moisture is removed during the drying process. After the drying is completed, the semi-finished raw materials are crushed to prevent agglomeration and affect the quality of the organic fertilizer.

[0060] (5) Take 6kg of urea, 4kg of monoammonium phosphate, 10kg of potassium magnesium sulfate, and 5kg of silicon-calcium fertilizer to make 25kg of chemical fertilizer;

[0061] 6. Add the chemical fertilizer prepared in the step 5 to the organic fertilizer, mix and stir to obtain a total of 100kg of mixture C;

[0062] (7) Grinding, st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com