Preparation method of moderate strength Al-Mg-Si alloy rods and alloy wires through natural ageing treatment

A technology of natural aging and aluminum alloy rods, applied in metal rolling, cable/conductor manufacturing, electrical components, etc., can solve the problems of artificial aging of high-strength aluminum-magnesium-silicon alloy rods or alloy wires, and achieve reduced production costs and stable performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] 1. Materials

[0051] Aluminum ingots, aluminum-silicon master alloys, aluminum-magnesium master alloys, and aluminum-rare-earth master alloys with certain composition requirements are selected as raw materials.

[0052] The specific composition requirements of aluminum ingots are as follows: Fe﹤0.20wt%, Si﹤0.07wt%, Cu﹤0.01wt%, Mg﹤0.02wt%, Zn﹤0.04wt%, B﹤0.04wt%, Cr﹤0.004wt%, ( Mn+Ti+Cr+V)﹤0.02wt%, the content of each other impurity element shall not exceed 0.03%wt%, and the total content of impurity elements shall not exceed 0.10wt%. (In this embodiment, electrical aluminum ingots with the brand Al99.7E are used)

[0053] The silicon content in the aluminum-silicon master alloy is 20wt%; the aluminum rare earth master alloy contains 10wt% mixed rare earths, of which the cerium content is not less than 45wt%; the magnesium ingot is the primary magnesium ingot of the brand Mg9998.

[0054] 2. Method

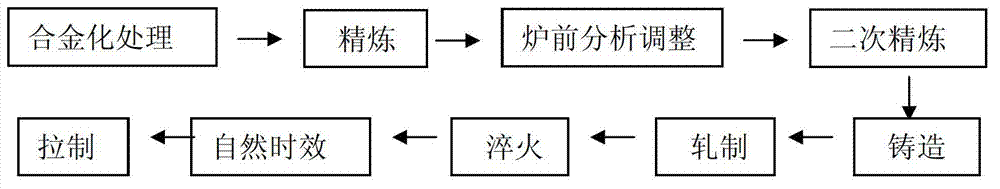

[0055] as per figure 1 In the process flow shown, the aluminum ingo...

Embodiment 2

[0058] 1. Materials

[0059] Aluminum ingots, aluminum-silicon master alloys, aluminum-magnesium master alloys, and aluminum-rare-earth master alloys with certain composition requirements are selected as raw materials.

[0060] The specific composition requirements of aluminum ingots are as follows: Fe﹤0.20wt%, Si﹤0.07wt%, Cu﹤0.01wt%, Mg﹤0.02wt%, Zn﹤0.04wt%, B﹤0.04wt%, Cr﹤0.004wt%, ( Mn+Ti+Cr+V)﹤0.02wt%, the content of each other impurity element shall not exceed 0.03%wt%, and the total content of impurity elements shall not exceed 0.10%. (In this embodiment, electrical aluminum ingots with the brand Al99.7E are used)

[0061] The silicon content in the aluminum-silicon master alloy is 20wt%; the aluminum-rare-earth master alloy contains 10wt% mixed rare earths, of which the cerium content is not less than 45wt%; the magnesium content in the aluminum-magnesium master alloy is 50wt%.

[0062] 2. Method

[0063] as per figure 1 In the process flow shown, the aluminum ingots ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com