Combined-type thermal-oxidation igniting process nozzle for gasifying solid powder fuel

A technology for fuel gasification and process burner, which is applied in the direction of granular/powder fuel gasification, burner, lighting and heating equipment, etc. The effect of prolonging the service life and simplifying the ignition process of the gasifier

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the present invention more comprehensible, a preferred embodiment is described in detail below with accompanying drawings.

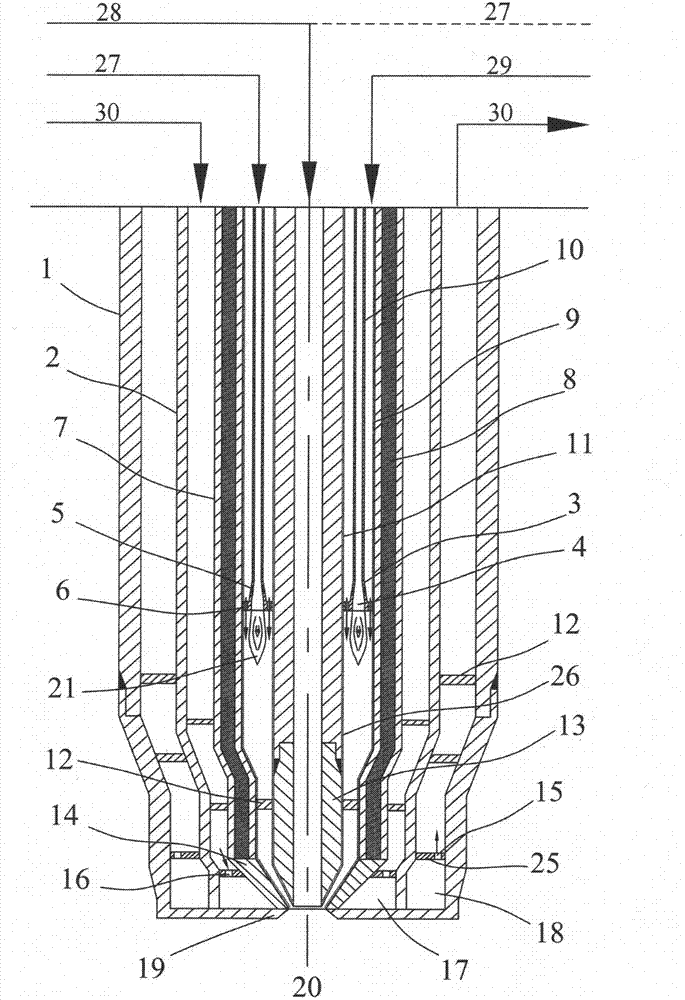

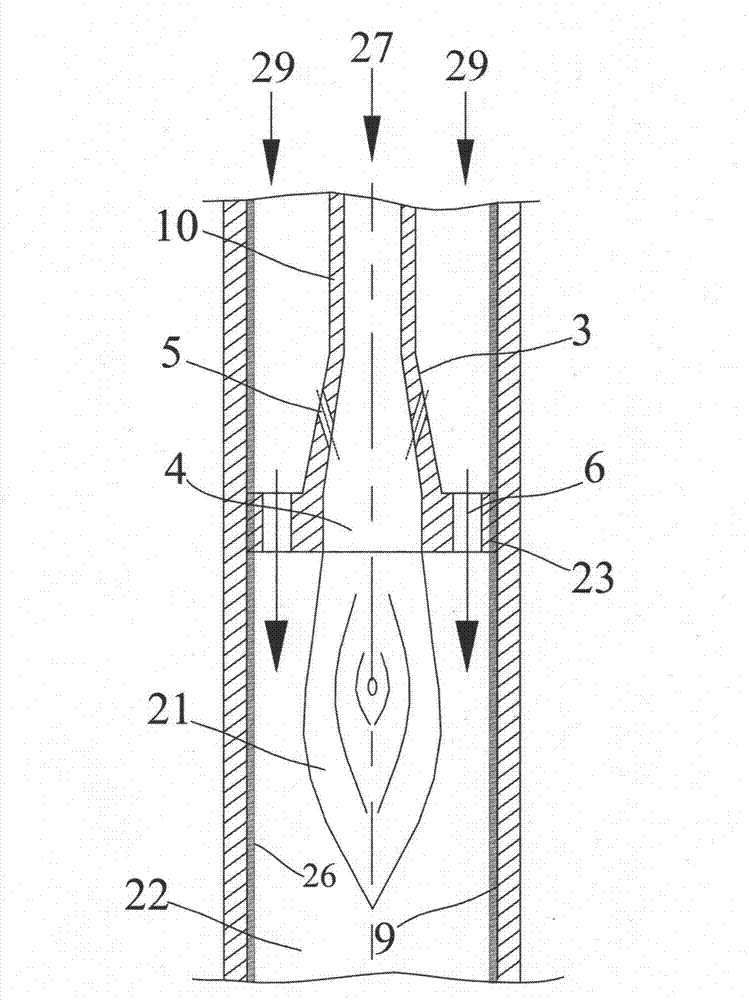

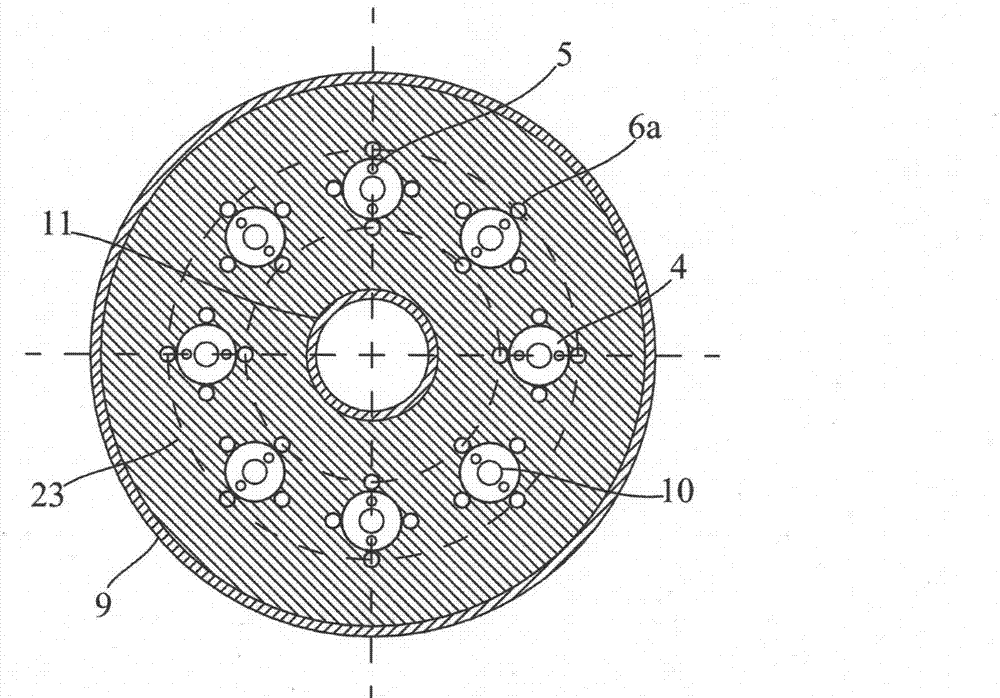

[0032] figure 1 A schematic diagram of the axial section structure of a composite thermal oxygen ignition process burner for the gasification of solid powder fuel provided by the present invention. The gasification burner for solid powder fuel includes a central channel 11 and a burner nozzle 20 The central nozzle 13 is located at the lower end of the central passage 11; 2 to 16 hot oxygen spray gun fuel passages 10 are uniformly installed outside the central passage 11 in a ring, and the outer wall 3 of the hot oxygen spray gun fuel passage 10 is provided with 2 to 10 side gasification agents Inlet 5, thermal oxygen spray gun fuel channel 10 is equipped with thermal oxygen spray gun burner 4 inside, the head of thermal oxygen spray gun burner 4 is provided with edge plate 23, has 2~12 gasification agent spouts 6 on the edge plate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com