Measuring method of equipment endogenous characteristics under unbalanced turbulence force effect

A measurement method and technology in equipment, applied in measurement devices, testing of machine/structural components, instruments, etc., can solve problems such as errors, and achieve the effects of good accuracy, high controllability, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is described in more detail below in conjunction with accompanying drawing example:

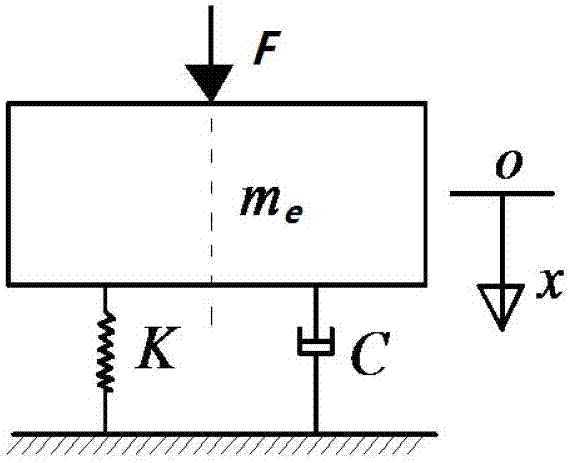

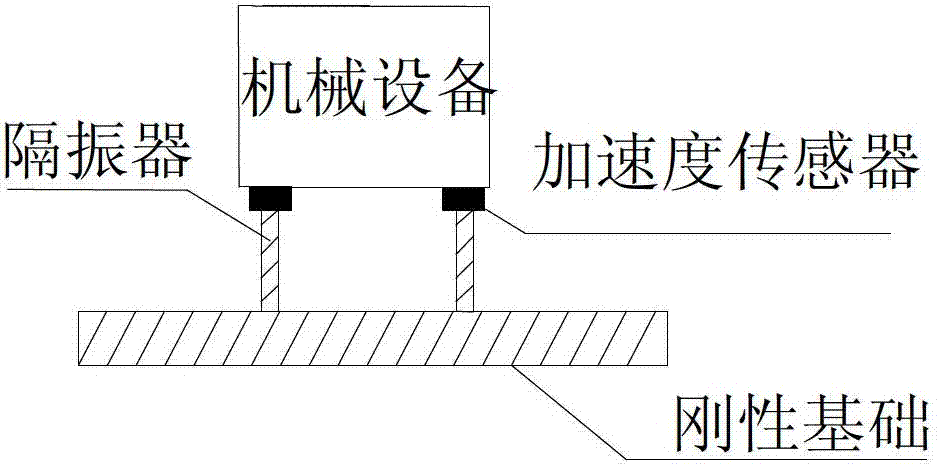

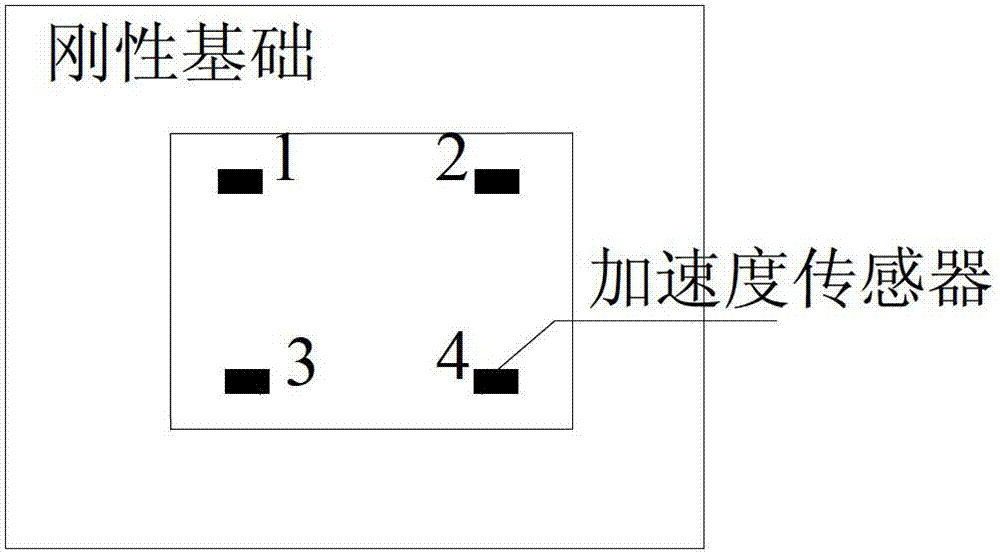

[0018] combine Figure 1~3 , the present invention comprises the following steps:

[0019] 1. Selection of installation base

[0020] Generally speaking, it is often assumed that the excitation force and equivalent mass at the center of mass of the equipment are constant, which can reflect the inherent vibration characteristics of the equipment and have nothing to do with other conditions. Therefore, it can be seen that choosing a rigid installation base or an elastic installation base has no effect on the endogenous characteristics of mechanical equipment. The endogenous characteristics of the equipment are only determined by the structure and processing accuracy of the equipment itself. Once the equipment is manufactured, its endogenous characteristics will be determined. If the elastic installation base is selected, the vibration system will be simplified to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com