Method for displaying and detecting void type defects in Czochralski silicon wafer

A technology of Czochralski silicon wafer and void type, which is applied in the semiconductor field, can solve the problems of complexity, difficulty in finding void type defects, and low density of void type defects, and achieve the effect of convenient application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

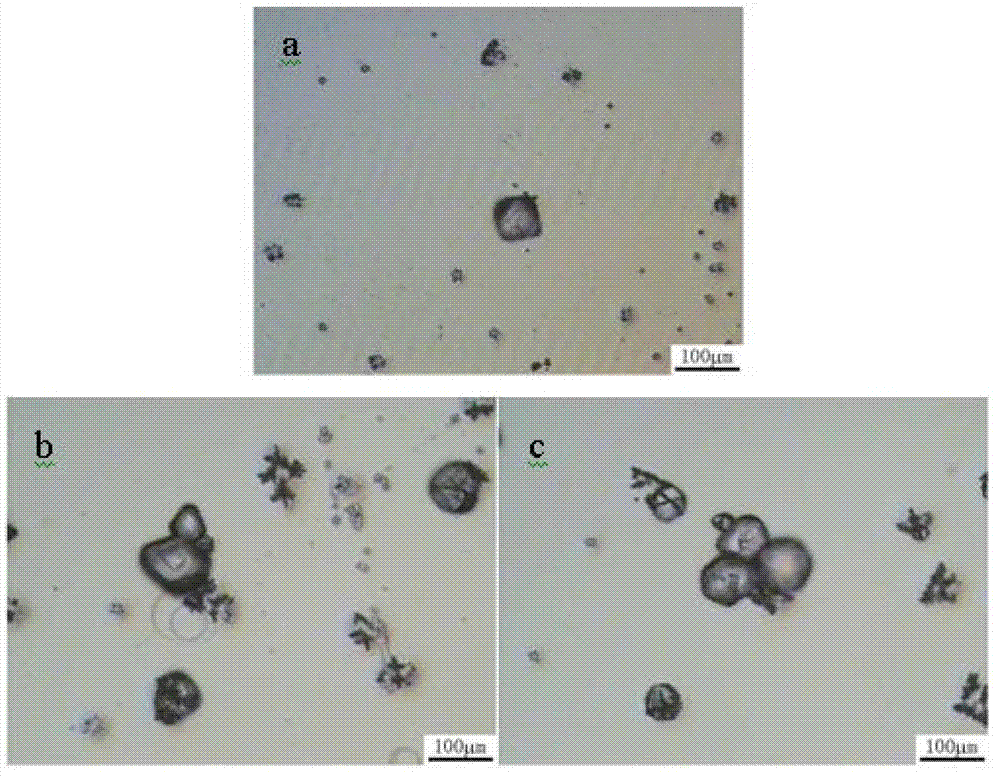

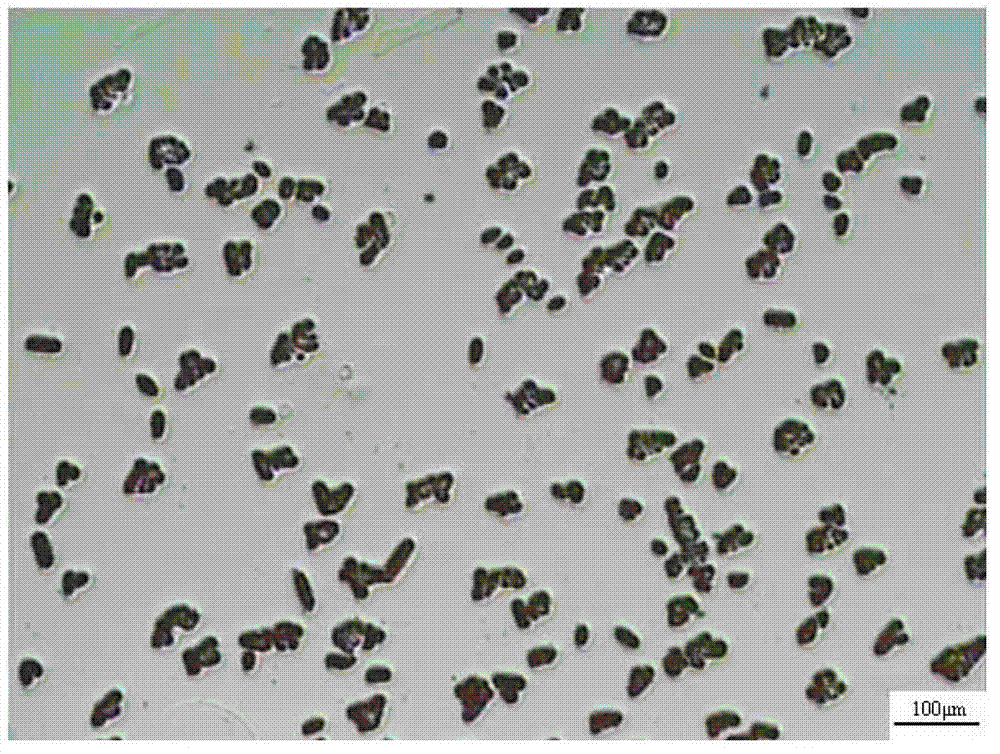

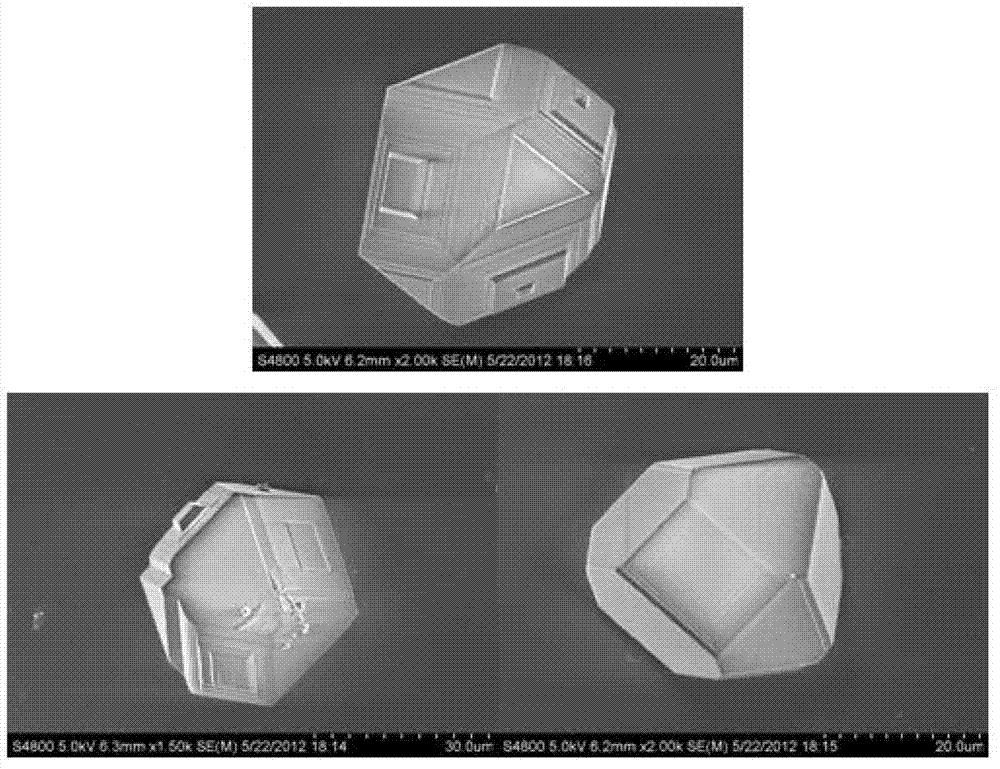

[0051] Select a boron-doped P-type Czochralski silicon single crystal with a diameter of 200 mm in crystal orientation and a resistivity of 8-12 Ω·cm. ) ratio greater than the critical value (0.2mm 2 min -1 K -1 ) grown under the conditions, so there are void-type defects in the silicon single crystal. Cut a silicon wafer on the single crystal, and make a single-sided polished Czochralski silicon wafer with a thickness of about 725 μm.

[0052] The specific steps for displaying the cavity-type defects in the above-mentioned polished Czochralski silicon wafer are:

[0053] (1) immersing the Czochralski wafer in a copper nitrate solution with a concentration of 8mol / L and a temperature of 10°C for 10 minutes to carry out copper contamination;

[0054] (2) then take out the Czochralski silicon wafer after the copper is stained, rinse the residual copper nitrate solution on the surface of the silicon wafer with deionized water, and then dry the silicon wafer;

[0055] (3) Pu...

Embodiment 2

[0064] A boron-doped P-type Czochralski silicon single crystal with a diameter of 200 mm in crystal orientation and a resistivity of 8-12 Ω·cm was selected. The single crystal is when the ratio of V / G (the axial temperature gradient of crystal pulling rate / solid-liquid interface) is greater than the critical value (0.2mm 2 min -1 K -1 ) grown under the conditions, so there are void-type defects in the silicon single crystal. Cut a silicon wafer on the single crystal, and make a single-sided polished Czochralski silicon wafer with a thickness of about 725 μm.

[0065] The specific steps for displaying the cavity-type defects on the above-mentioned polished Czochralski wafer are:

[0066] (1) Immerse the Czochralski wafer in a copper nitrate solution with a concentration of 12mol / L and a temperature of 40°C for 5 minutes for copper contamination

[0067] (2) then take out the Czochralski silicon wafer after the copper is stained, rinse the residual copper nitrate solution o...

Embodiment 3

[0077] A boron-doped P-type Czochralski silicon single crystal with a diameter of 200 mm in crystal orientation and a resistivity of 8-12 Ω·cm was selected. The single crystal is when the ratio of V / G (the axial temperature gradient of crystal pulling rate / solid-liquid interface) is greater than the critical value (0.2mm 2 min -1 K -1 ) grown under the conditions, so there are void-type defects in the silicon single crystal. Cut a silicon wafer on the single crystal, and make a single-sided polished Czochralski silicon wafer with a thickness of about 725 μm.

[0078] The specific steps for displaying the cavity-type defects on the above-mentioned polished Czochralski wafer are:

[0079] (1) immersing the Czochralski wafer in a copper nitrate solution with a concentration of 4mol / L and a temperature of 25°C for 20 minutes to carry out copper contamination;

[0080](2) then take out the Czochralski silicon wafer after the copper is stained, rinse the residual copper nitrate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com