Mg<2+>, Al<3+>, Zr<4+> and S<2-> ion co-doped garnet type solid electrolyte

A solid electrolyte, garnet-type technology, applied in the direction of circuits, electrical components, secondary batteries, etc., can solve the problems that researchers of garnet-type solid electrolyte lithium ion migration mechanism have figured out, and achieve the promotion of lithium ion migration and force Weak, activation energy-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

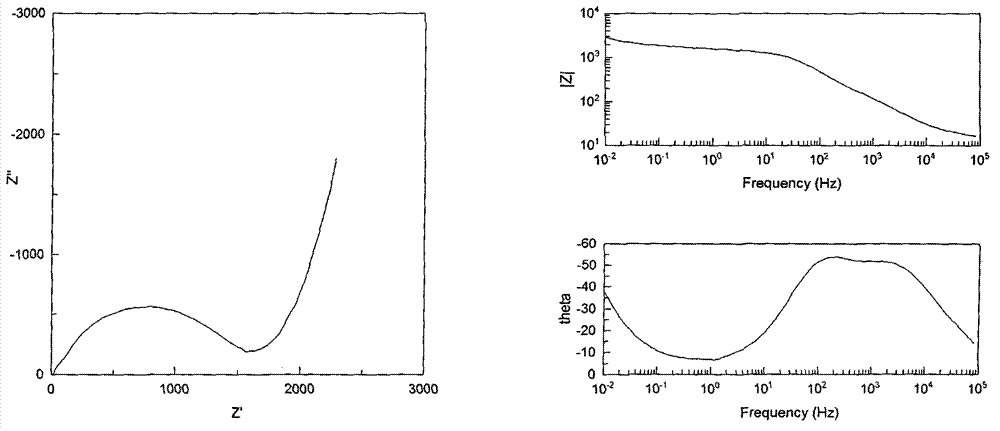

Image

Examples

Embodiment 1

[0011] Embodiment 1: Li 2 CO 3 : La 2 o 3 :MgO:Al 2 o 3 : ZrO 2 ; Nb 2 o 5 : thiourea is 2.81: 1.375: 0.25: 0.06: 0.13: 0.875: 0.15 (molar ratio) ratio is evenly mixed, adds 3.2% 95% ethanol, ball mills 10 hours with the rotating speed of 250 rev / mins in ball mill, ball mill finishes Afterwards, dry in a 60°C vacuum oven (vacuum degree 20Pa) for 10 hours, take it out and grind it again in an agate mortar for 30 minutes, and the ground powder is heated to 220°C at a rate of 5°C / min for 3 hours, and then Raise the temperature at a rate of 5°C / min to 720°C for 10 hours, then raise the temperature at a rate of 3°C / min to 900°C for 11 hours to prepare a solid electrolyte powder. The powder is mixed with 2wt% binder PVC and kept under a pressure of 300MPa under a press for 5 minutes to form a thin sheet. The thin sheet is heated to 1000°C at a rate of 11°C / min and kept for 10 hours in an air atmosphere to make a lithium ion solid Electrolyte sheets.

Embodiment 2

[0012] Embodiment 2: Li 2 CO 3 : La 2 o 3 :MgO:Al 2 o 3 : ZrO 2 : Nb 2 o 5 : thiourea is 2.94: 1.3: 0.4: 0.07: 0.2: 0.83: 0.16 (molar ratio) ratio is uniformly mixed, adds 5.5% 95% ethanol, ball mills 15 hours with the rotating speed of 380 rev / mins in ball mill, ball mill finishes Afterwards, dry in a vacuum oven (vacuum degree 95Pa) at 80°C for 30 hours, take it out and re-grind in an agate mortar for 30 minutes, and the ground powder is heated to 250°C at a rate of 6°C / min and kept for 5 hours, and then Raise the temperature at a rate of 8°C / min to 780°C for 10 hours, then raise the temperature at a rate of 7°C / min to 1000°C for 15 hours to prepare a solid electrolyte powder. The powder is mixed with 5wt% binder PVC and kept under a pressure of 450MPa under a press for 2 minutes to form a thin sheet. The thin sheet is heated to 1050°C at a rate of 15°C / min and kept for 10 hours in an air atmosphere to make a lithium-ion solid electrolyte. Flakes.

Embodiment 3

[0013] Embodiment 3: with Li 2 CO 3 : La 2 o 3 :MgO:Al 2 o 3 : ZrO 2 : Nb 2 o 5 : thiourea is 2.7: 1.45: 0.1: 0.05: 0.1: 0.9: 0.12 (molar ratio) ratio is evenly mixed, adds 3% 95% ethanol, ball mills 20 hours with the rotating speed of 300 rev / mins in ball mill, ball mill finishes Afterwards, dry in a 70°C vacuum oven (vacuum degree 50Pa) for 20 hours, take it out and re-grind in an agate mortar for 10 minutes, and the ground powder is heated to 270°C at a rate of 9°C / min and kept for 5 hours, and then Raise the temperature at a rate of 10°C / min to 800°C for 7 hours, then raise the temperature at a rate of 2°C / min to 1050°C for 12 hours to prepare a solid electrolyte powder. The powder is mixed with 1wt% binder PVA and kept under a pressure of 300MPa under a press for 6 minutes to form a thin sheet, which is heated to 1100°C at a rate of 15°C / min and kept for 18 hours in an air atmosphere to make a lithium ion solid Electrolyte sheets.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com