Noise interference-proof high-side gate drive circuit

A driving circuit and anti-noise technology, applied in the field of common mode noise elimination circuit design, to achieve the effects of low power consumption, filtering out common mode noise, and small overall delay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

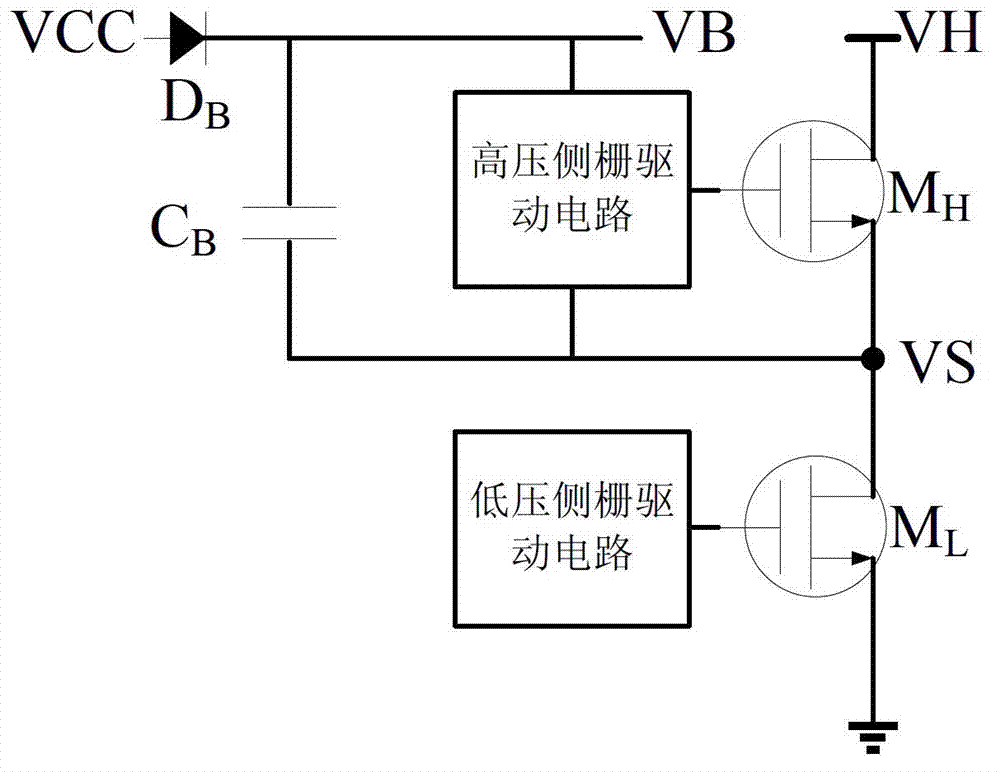

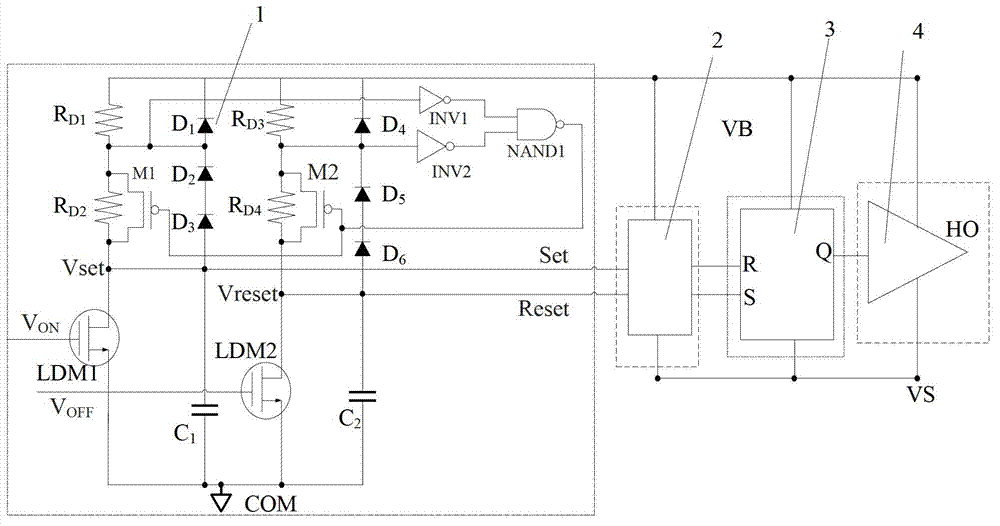

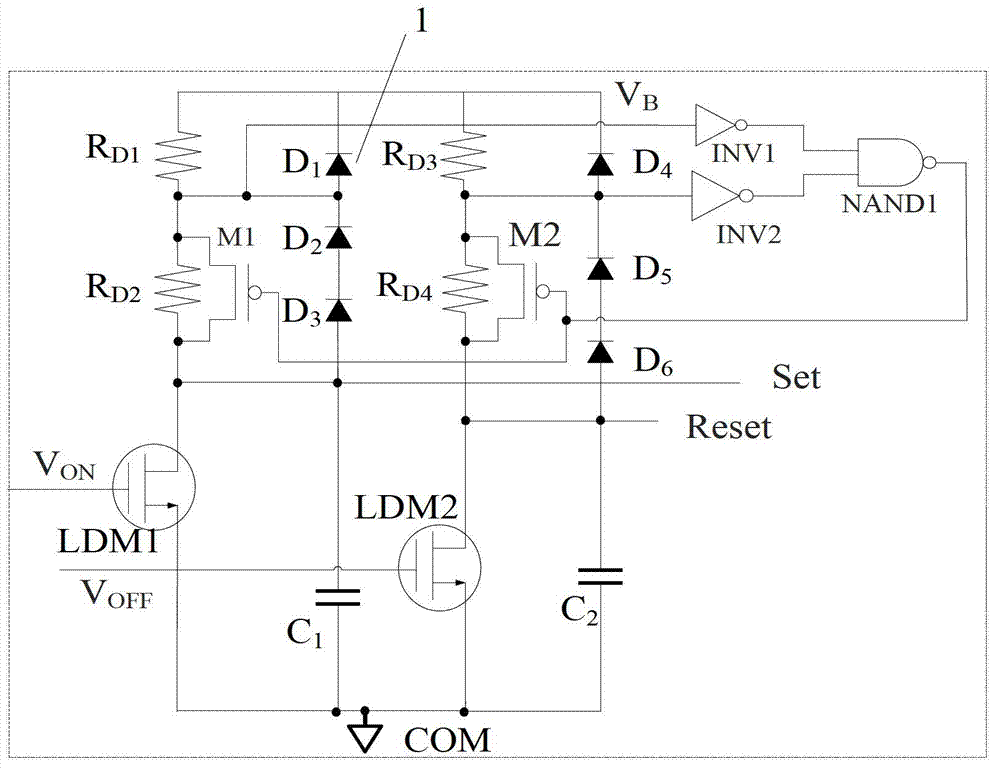

[0022] like figure 1 and figure 2 As shown, a high-side gate drive circuit that can resist noise interference includes a high-voltage level shift circuit 1 that can resist common-mode noise interference, a pulse filter circuit 2, an RS flip-flop 3, and an output driver stage circuit 4, which can be The input of the high-voltage level shift circuit 1 against common-mode noise interference is provided by the low-voltage side pulse generation circuit, and its output is used as the input of the pulse filter circuit 2, and the output signal of the pulse filter circuit 2 enters the output driver circuit through the RS flip-flop 3 4. The output drive stage circuit 4 outputs a drive signal to control the switch of the external power tube. The high-voltage level shift circuit 1 that can resist common mode noise interference is composed of LDMOS tube LDM1, LDMOS tube LDM2, and capacitor C 1 , capacitance C 2 , PMOS tube M1, PMOS tube M2, resistor R D1 , resistor R D2 , resistor R ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com