Duplex stainless steel material for vacuum vessels, and process for manufacturing same

A duplex stainless steel, an unavoidable technology, applied in the direction of manufacturing tools, furnace types, furnaces, etc., to achieve excellent gas release characteristics and excellent strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

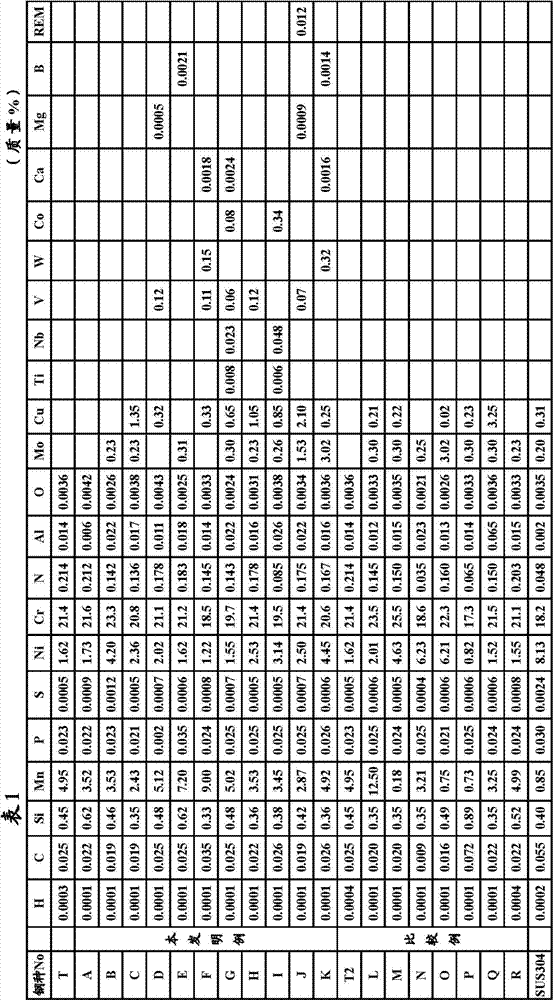

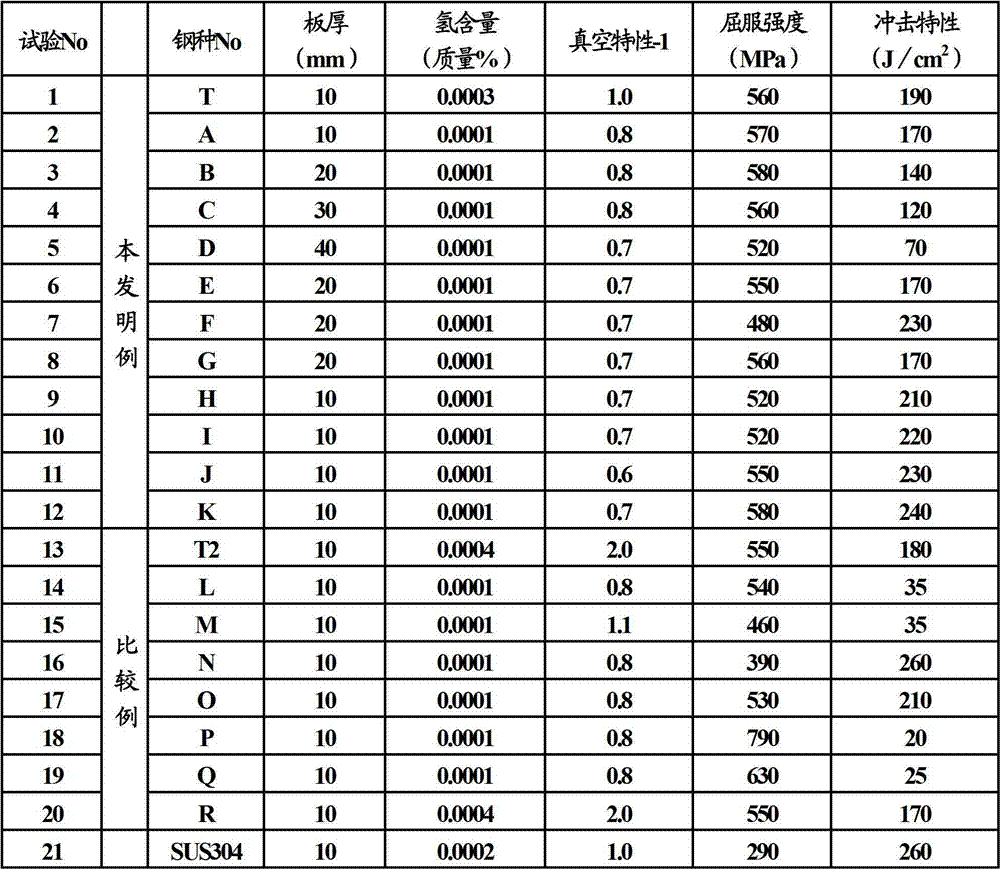

[0064] The present invention will be described more specifically by way of examples below. Table 1 shows the chemical composition of the tested steels. In addition, components other than those described in Table 1 are Fe and unavoidable impurity elements. In addition, with respect to the components shown in Table 1, the part where the content is not described shows the impurity level. In addition, REM in a table|surface means a lanthanide rare earth element, and content shows the total of those elements.

[0065] The steel billet of steel type number T is produced from the actual machine melting slab, and the steel billet with a thickness of 80 mm is used as a hot rolling billet. The steels with steel grade numbers A to Q are smelted in a 50kg vacuum induction furnace in the laboratory, and the steels of R are smelted in a 50kg atmospheric melting furnace, cast into flat steel blocks with a thickness of about 110mm, and then made into 80mm thick steel blocks by hot forging. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com