Method for determining heat transfer coefficient of secondary cooling zones in steel continuous casting process

A heat transfer coefficient and determination method technology, applied in the field of iron and steel metallurgy, can solve the problems of being unable to withstand the straightening stress and the thermal stress of the slab, the inability to measure the surface temperature of the slab, and the inapplicability of continuous casting of the slab, so as to avoid Effects of hazard and inflexibility of tactile measurements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

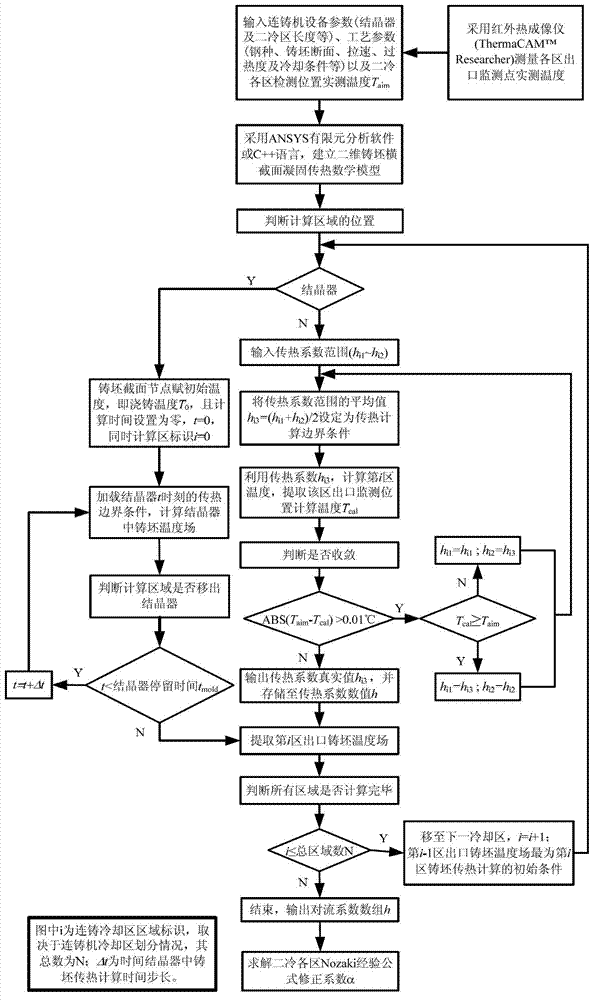

Method used

Image

Examples

Embodiment 1

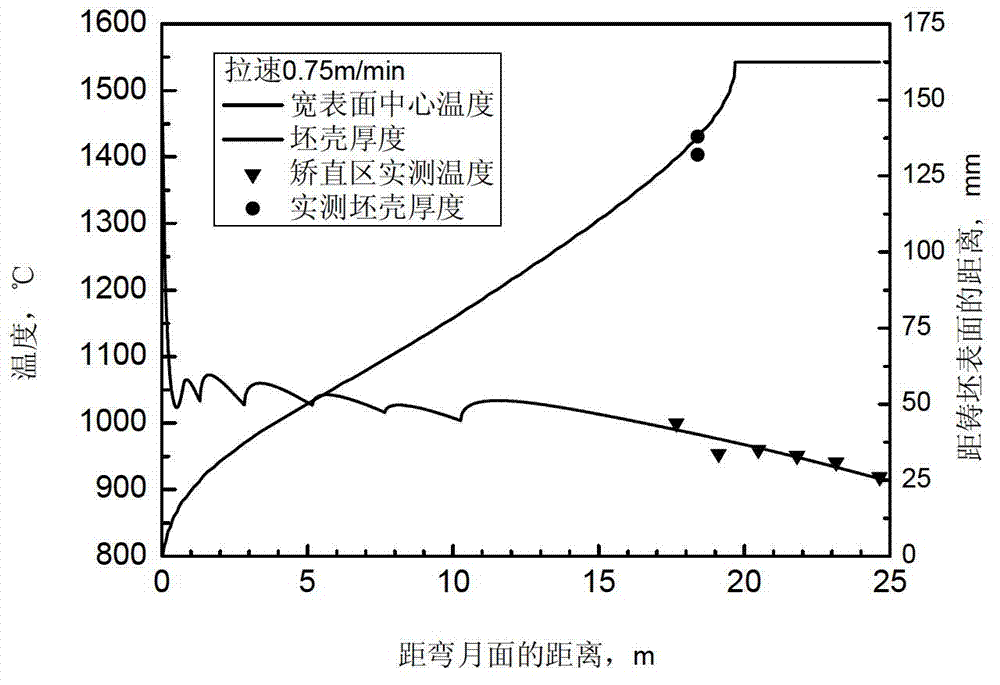

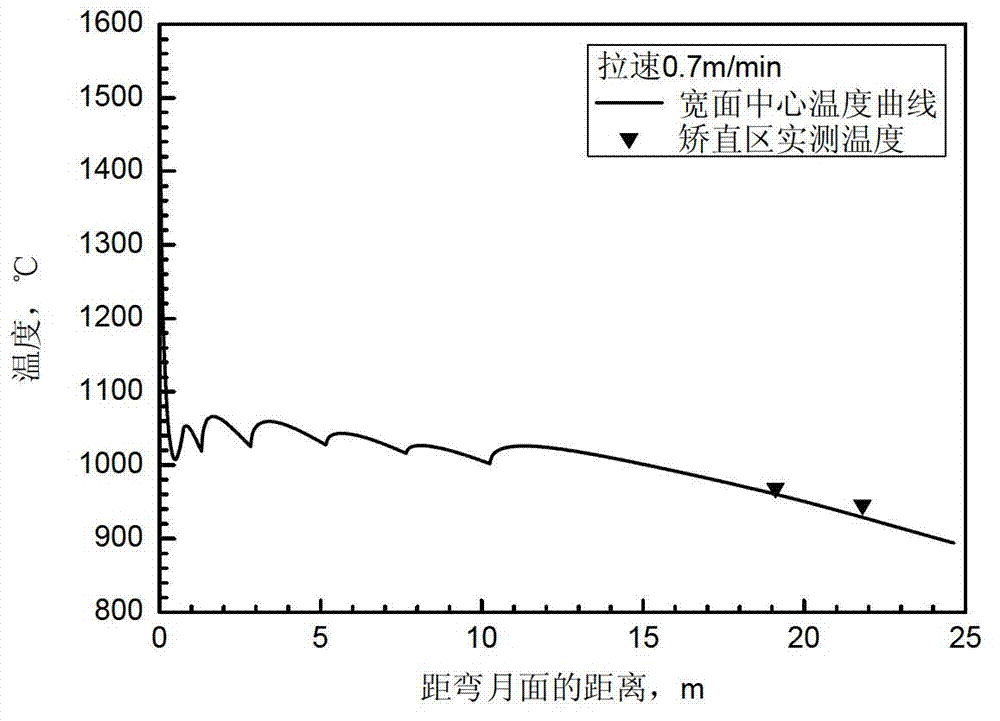

[0043] Application of Model in Bloom Continuous Casting Process

[0044] First, measure the temperature at the outlet of the secondary cooling zone: use an infrared thermal imager to measure the actual temperature at the outlet of the 5 secondary cooling zones of the bloom, and record the data for 4 minutes;

[0045] Then establish the solidification heat transfer model: the relevant parameters of the casting machine are: ① casting machine section: 280×325mm×mm; ② casting machine length: 33.149m; ③ casting speed: 0.7 and 0.75m / min; L / kg; ⑤C content: 0.35%; ⑥Casting temperature: 1502°C, the grid size of the solid model is controlled at 1mm, and the mathematical model of solidification and heat transfer of the bloom is established according to the continuous casting process parameters;

[0046] ρ ( T ) c ( T ) ∂ T ...

Embodiment 2

[0055] Example 2: Application of the model in continuous casting of wide and thick slabs

[0056] First, measure the temperature at the outlet of the secondary cooling zone. The measured temperature at the outlets of 8 secondary cooling zones for wide and thick slabs was measured with an infrared thermal imager, and the data recording time was 6 minutes.

[0057] Then establish the solidification heat transfer model: the relevant parameters of the casting machine are: ① casting machine section: 210×2100mm×mm; ② casting machine length: 34.58m; ③ casting speed: 0.9m / min; ④ specific water volume: 0.59L / kg; ⑤C content: 0.13%; ⑥Casting temperature: 1546°C, the grid size of the solid model is controlled at 2mm after discrete, and a mathematical model of solidification and heat transfer of wide and thick slabs is established according to the continuous casting process parameters;

[0058] ρ ( T ) c ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com