A laser motion trajectory control system for a rotating beam module group

A technology of rotating beam and motion trajectory, applied in the fields of laser processing, cutting and drilling, and laser milling, it can solve the problems of inability to fill and rotate, difficult to control the processing effect, large workload, etc., and achieve easy solid circle filling processing, hole type Good, high-quality edge effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

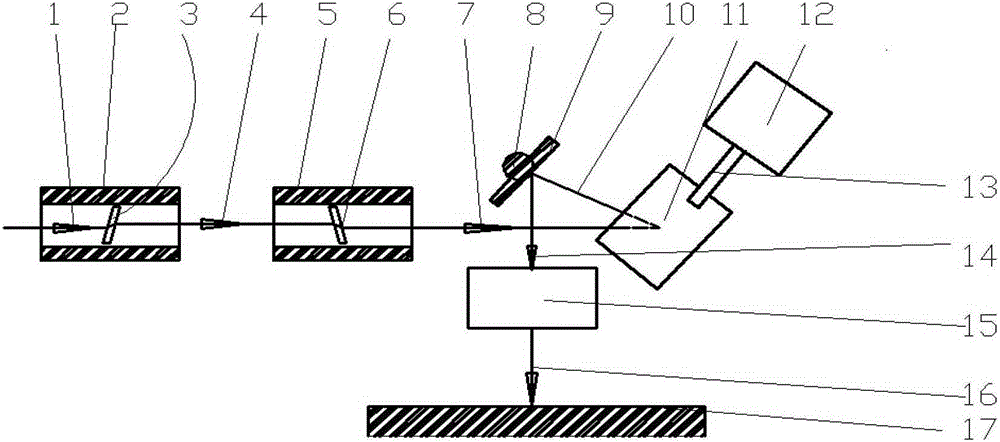

[0022] figure 1 Schematic diagram of the device structure for drilling stainless steel sheets, by figure 1 It can be seen that the laser motion trajectory control system of the rotating beam module group in the stainless steel sheet drilling includes incident light 1, the first rotating beam device cylinder 2, the second rotating beam device cylinder 5, the second reflecting mirror 9 of the vibrating mirror, and the motor of the vibrating mirror. 12. The first reflective mirror 11 of the vibrating mirror, the telecentric focusing mirror 15 and the workpiece 17 to be processed.

[0023] The workpiece 17 to be processed is a thin stainless steel plate with a thickness of 0.5 mm.

[0024] The incident light 1 is an incident expanded collimated beam with a diameter of 5 mm.

[0025] The first rotating beam device barrel 2 is provided with a flat sapphire glass 3, the thickness of the flat sapphire glass 3 is 0.5 mm, and it is obliquely arranged in the first rotating beam device ...

Embodiment 2

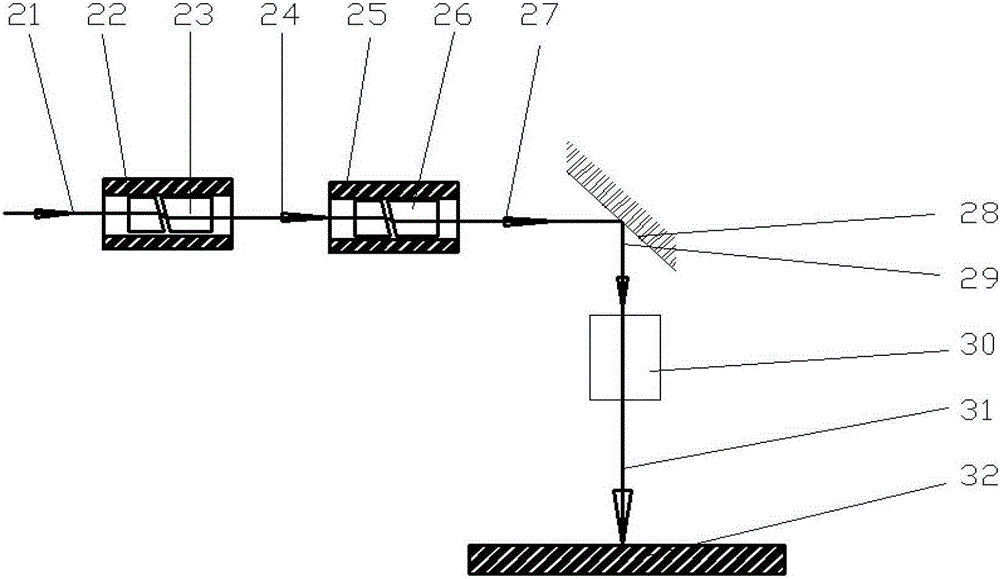

[0045] figure 2 Schematic diagram of the device structure for drilling ceramic blind vias, by figure 2 It can be seen that the laser movement trajectory control system of the rotating beam module group in ceramic blind hole drilling includes incident light 21, a first rotating beam device sleeve 22, a second rotating beam device sleeve 25, a laser reflective lens 28, a static focusing mirror 30 and The workpiece 32 to be processed.

[0046] The workpiece 32 to be processed is an alumina ceramic sheet with a thickness of 1 mm.

[0047] The incident light 21 is an incident expanded collimated light beam with a diameter of 5 mm.

[0048] The sleeve 22 of the first rotating beam device is provided with two opposing optical wedge assemblies 23 .

[0049] After the incident ray 21 passes through the first rotating beam device sleeve 22, a collimated output beam 24 is obtained, and the collimated output beam 24 is parallel to the incident ray 21, and the parallel distance betwee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com