Macromolecule pre-laid waterproof coiled material

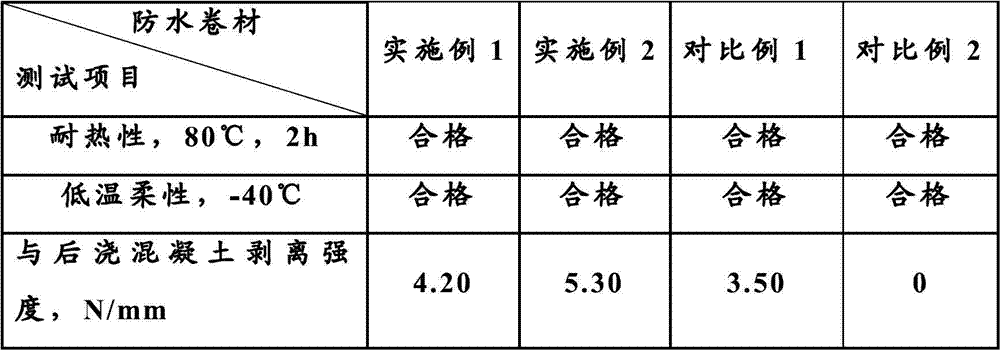

A waterproofing membrane, polymer technology, applied in the direction of layered products, adhesive types, synthetic resin layered products, etc., can solve the problems of low bonding peel strength, troublesome construction, poor high temperature and low temperature performance, etc. To achieve the effect of improving the peeling and bonding performance, avoiding the delay of the construction period and strengthening the bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

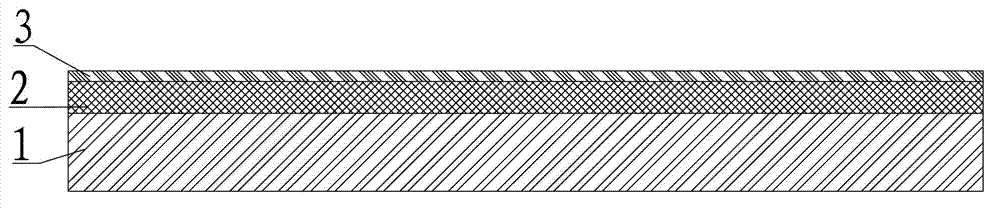

[0025] This embodiment provides a polymer pre-laid waterproof membrane. Such as figure 1 As shown, the polymer pre-paved waterproof membrane has a three-layer structure. Specifically, the polymer pre-laid waterproof roll includes a polymer substrate 1 , a polymer adhesive layer 2 covering the polymer substrate, and a protective layer 3 covering the polymer adhesive layer 2 .

[0026] The polymer substrate 1 is a waterproof sheet with a thickness of 1.0 mm made of high-density polyethylene pellets mixed at high and low speeds into a twin-screw extruder and shaped by a die. Control the temperature of each section of the twin-screw extruder, the temperature of the feeding section is room temperature, the compression section is 90-140°C, and the metering section is 180°C.

[0027] The formation method of polymer adhesive layer 2 is: according to the weight ratio of SBS rubber: naphthenic oil: hydrogenated petroleum resin=10:5:12, antioxidant 1010, ultraviolet stabilizer UVP and ...

Embodiment 2

[0031] This embodiment provides a polymer pre-laid waterproof membrane, the structure of which is the same as that of Embodiment 1. The difference is that:

[0032] The polymer substrate 1 is a waterproof sheet with a thickness of 1.0 mm made of polyethylene terephthalate mixed at high and low speeds into a twin-screw extruder and shaped by a die. Control the temperature of each section of the twin-screw extruder, the temperature of the feeding section is room temperature, the compression section is 90-140°C, and the metering section is 180°C.

[0033] The formation method of polymer adhesive layer 2 is: according to the weight ratio of polyisobutylene rubber: naphthenic oil: hydrogenated petroleum resin=10:5:12, antioxidant 1010, ultraviolet stabilizer UVP and calcium carbonate are according to 5% of total amount ‰, 7‰, and 10% are added to the feeder of the screw extruder to control the temperature of each section of the twin-screw extruder. The temperature of the feeding s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Peel strength value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com