Method for preparing isooctyl thioglycolate by utilizing thionocarbamate tail liquid

A technology of isooctyl thioglycolate and thiourethane, which is applied in the preparation of mercaptans, organic chemistry and other directions, can solve the problems of unstable product quality, unsafe handling of ether, and difficult operation, and achieves outstanding substantive features and reduces The effect of removing impurities and reducing operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

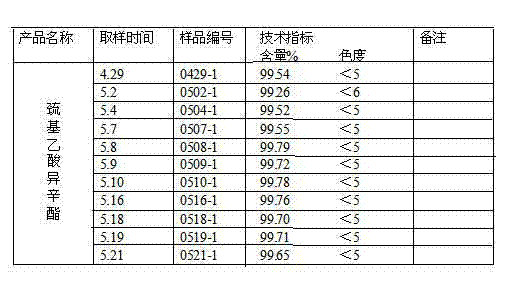

Examples

Embodiment 1

[0016] Example 1, the thiourethane tail liquid and the xylene extractant are uniformly mixed under normal pressure at a molar ratio of 1:7, and the tail liquid is removed for impurity removal; dilute hydrochloric acid is added for acidification while removing impurities, and the adjustment pH 4 ~5; After the acidification is completed, let it stand for stratification, separate the bottom acidification solution, and keep the xylene extractant in the upper layer for recycling in the original process; under the condition of stirring in the acidification solution, add 1%-2% zinc powder of the weight of the acidification solution to make the acidification solution It is colorless; the esterification liquid is subjected to multi-stage continuous extraction with isooctyl alcohol in the extraction tank, the content of thioglycolic acid in the extraction liquid is 55%-60%, and the content of thioglycolic acid in the tail liquid is ≤0.2%; in the extraction liquid , adding 0.2% benzenesu...

Embodiment 2

[0020] Example 2, the thiourethane tail liquid and the toluene extractant are uniformly mixed under normal pressure at a molar ratio of 1:6 to remove impurities from the tail liquid; while removing impurities, dilute hydrochloric acid is added to acidify and adjust the pH value 4 ~5; After the acidification is completed, let it stand for stratification, separate the bottom acidification solution, and keep the toluene extractant in the upper layer for recycling; under the condition of stirring in the acidification solution, add zinc powder of 1%-2% of the weight of the acidification solution to make the acidification solution reach Colorless; the esterification liquid is subjected to multi-stage continuous extraction with isooctyl alcohol in the extraction tank, the content of thioglycolic acid in the extraction liquid is 55%-60%, and the content of thioglycolic acid in the tail liquid is ≤0.2%; in the extraction liquid, Add 0.02% benzenesulfonic acid catalyst of the weight of ...

Embodiment 3

[0021] Example 3, the thiourethane tail liquid and the dinitrobenzene extractant are uniformly mixed under normal pressure at a molar ratio of 1:8, and the tail liquid is removed; while removing impurities, dilute hydrochloric acid is added for acidification , adjust the pH value to 4 ~5; After the acidification is completed, let it stand for stratification, separate the bottom acidification solution, and keep the dinitrobenzene extractant in the upper layer for recycling; under the condition of stirring in the acidification solution, add zinc powder of 1%-2% of the weight of the acidification solution to make The acidified solution is colorless; the esterified solution is subjected to multi-stage continuous extraction with isooctyl alcohol in the extraction tank, the content of thioglycolic acid in the extraction solution is 55%-60%, and the content of thioglycolic acid in the extraction tail liquid is ≤0.2%; In the liquid, add 0.5% benzenesulfonic acid catalyst of the weight...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com