Preparation method of high-salt resistance high-viscosity sodium carboxymethylcellulose

A technology of sodium carboxymethyl cellulose and high viscosity, which is applied in the direction of earthwork drilling, mining fluid, wellbore/well parts, etc. It can solve problems such as poor salt resistance, reduce energy, reduce friction, and improve The effect of viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

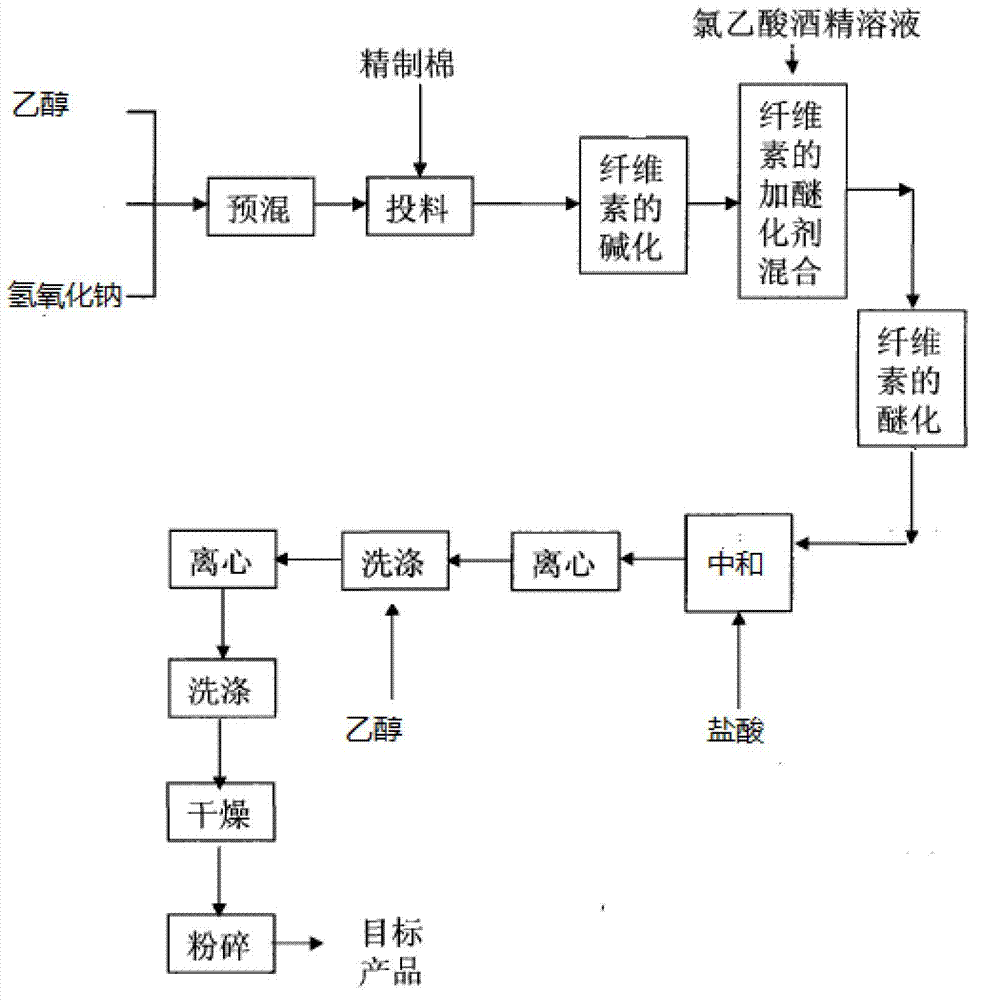

[0015] see figure 1 . The preparation method of the high-salt-resistant high-viscosity sodium carboxymethyl cellulose described in this specific embodiment uses refined cotton as the cellulose raw material, comprising the following steps:

[0016] 1) Premixing: pre-mix a certain amount of sodium hydroxide solution with a weight concentration of 45-52% and an ethanol solution with a weight concentration of 86-96% in a mixing container at a weight ratio of 1:1-3, and cool to 10-30°C.

[0017] 2) Feeding: Add the premixed sodium hydroxide ethanol solution into a kneader with a pair of "S" shaped shafts that rotate in opposite directions along the axis, and evenly put the shredded refined cotton into the kneader Among them, the feeding time is 5~15min, and the average degree of polymerization of refined cotton is 3000~3300. The weight ratio of refined cotton to sodium hydroxide solution is controlled at 1:1-3, and the weight ratio to ethanol solution is 1:1.2-5.

[0018...

Embodiment 1

[0027] In advance, mix 1.35 parts of sodium hydroxide solution with a weight concentration of 49% and 1.6 parts of an ethanol solution with a weight concentration of 92% and cool it below 25°C, add it to the kneader, and then put 1 part of special refined cotton into it. Finally, the feeding port of the kneader is closed, and nitrogen gas is charged until the alkalization is completed. The alkalization reaction takes 30-70 minutes, and the alkalization temperature is controlled at 15-30°C. After the alkalization is completed, 1.08 parts of chloroacetic acid solution with a weight concentration of 65-78% is added for etherification for 30-60 minutes, and the etherification temperature is controlled at 30 -50°C. After the addition of chloroacetic acid, the temperature is raised to 75-80°C, and the etherification is continued for 40-80 minutes. After the etherification is completed, the material is discharged and the pH is neutralized to 6.5-7.5. After washing and refining, eth...

Embodiment 2

[0030] Mix 1.4 parts of sodium hydroxide solution with a weight concentration of 50% and 1.7 parts of an ethanol solution with a weight concentration of 94% in advance and cool it to below 25°C, add it to the kneader, and then put 1 part of special refined cotton into it. Finally, the feeding port of the kneader is closed, and nitrogen gas is charged until the alkalization is completed. The alkalization reaction takes 30-70 minutes, and the alkalization temperature is controlled at 15-30°C. After the alkalization is completed, 1.1 parts of chloroacetic acid solution with a weight concentration of 65-78% is added for etherification for 30-60 minutes, and the etherification temperature is controlled at 30 -50°C. After the addition of chloroacetic acid, the temperature is raised to 75-80°C, and the etherification is continued for 40-80 minutes. After the etherification is completed, the material is discharged and the pH is neutralized to 6.5-7.5. After washing and refining, eth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com