Polishing composition for improving surface quality of sapphire

A technology for polishing composition and surface quality, which is applied in the direction of polishing composition containing abrasives, etc. It can solve the problems of undisclosed ways to improve surface quality, and achieve the effects of improving smoothness, reducing roughness, and easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

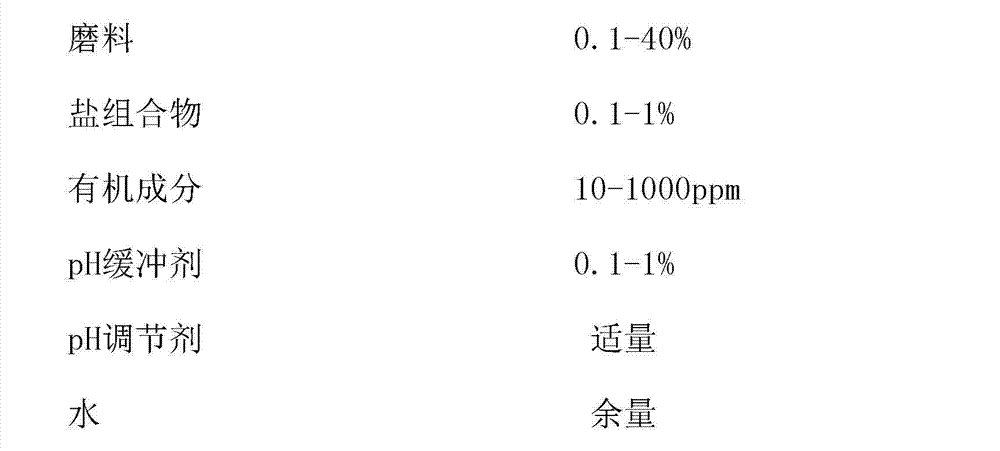

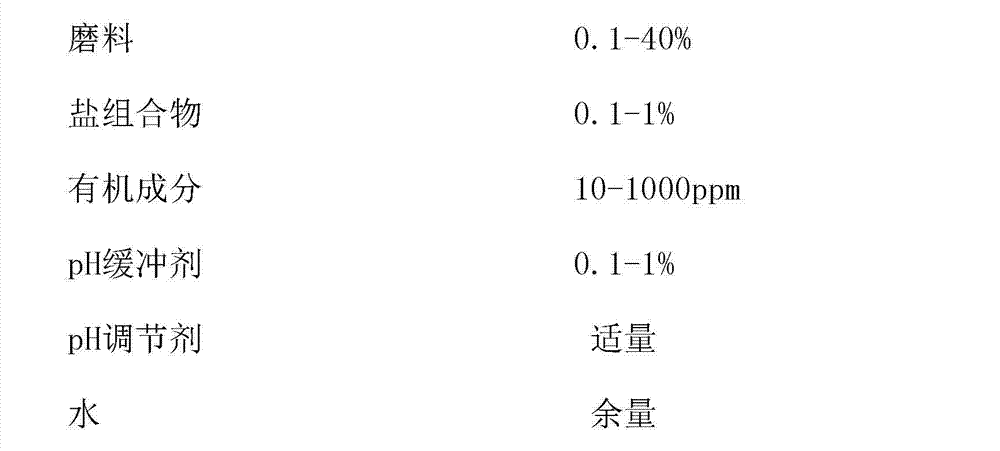

Method used

Image

Examples

Embodiment 1

[0020] Take 10kg of commercially available silica sol (Qingdao Yumin, the same below), concentration 40%, particle size 60nm, add deionized water to dilute to 20kg, add 20g potassium carbonate, adjust the pH value to 10.8 with 10% KOH solution, ultrasonicate and stir 5 minutes; add 400g NaCl, sonicate and stir for 5 minutes; add 0.4g hydroxyethyl cellulose, sonicate and stir for 5 minutes.

[0021] Polish using a speedfam SPAW model 32 polisher. Pressure 300g / cm 2 , speed 40rpm, temperature 36°C, polishing pad suba600. After polishing with (1000) sapphire for 2 hours, it was ultrasonically cleaned with deionized water for 10 minutes. The pit-shaped defects, point-like defects and roughness were observed by interference microscope and atomic force microscope, respectively. The results were 0 pit defects, 2 point defects and a roughness of 0.28 nm.

Embodiment 2

[0023] Take 10kg of commercially available silica sol, concentration 40%, particle size 60nm, add deionized water to dilute to 20kg, add 20g potassium carbonate, adjust the pH value to 10.6 with 5% NaOH solution and stir for 5 minutes; add 200g NaCl, sonicate and Stir for 5 minutes; add 0.4 g of polyvinyl alcohol, sonicate and stir for 5 minutes.

[0024] Polish using a speedfam SPAW model 32 polisher. Pressure 300g / cm 2 , speed 40rpm, temperature 36°C, polishing pad suba600. After polishing with (1000) sapphire for 2 hours, it was ultrasonically cleaned with deionized water for 10 minutes. Interference microscopy and atomic force microscopy were used to observe pit-shaped defects, point-like defects and roughness, respectively. The results were 0 pit defects, 0 point defects and a roughness of 0.16 nm.

Embodiment 3

[0026] Take 10kg of commercially available alumina solution, concentration 10%, particle size 60nm, add deionized water to dilute to 20kg, add 20g potassium carbonate, adjust pH value to 10.8 with 10% KOH solution, ultrasonic and stir for 5 minutes; add 20g KCl, Sonicate and stir for 5 minutes; add 0.2 g of hydroxyethyl cellulose, sonicate and stir for 5 minutes.

[0027] Polish using a speedfam SPAW model 32 polisher. Pressure 300g / cm 2 , speed 40rpm, temperature 36°C, polishing pad suba600. After polishing with (1000) sapphire for 2 hours, it was ultrasonically cleaned with deionized water for 10 minutes. The pit-shaped defects, point-like defects and roughness were observed by interference microscope and atomic force microscope, respectively. The results were 0 pit defects, 0 point defects and a roughness of 0.31 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com