Full-hydraulic self-moving type template device of vertical shaft wall

A self-moving, full-hydraulic technology, applied in shaft equipment, shaft lining, mining equipment, etc., can solve problems such as low work efficiency, template jamming, cumbersome operation, etc., and achieve the effect of convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

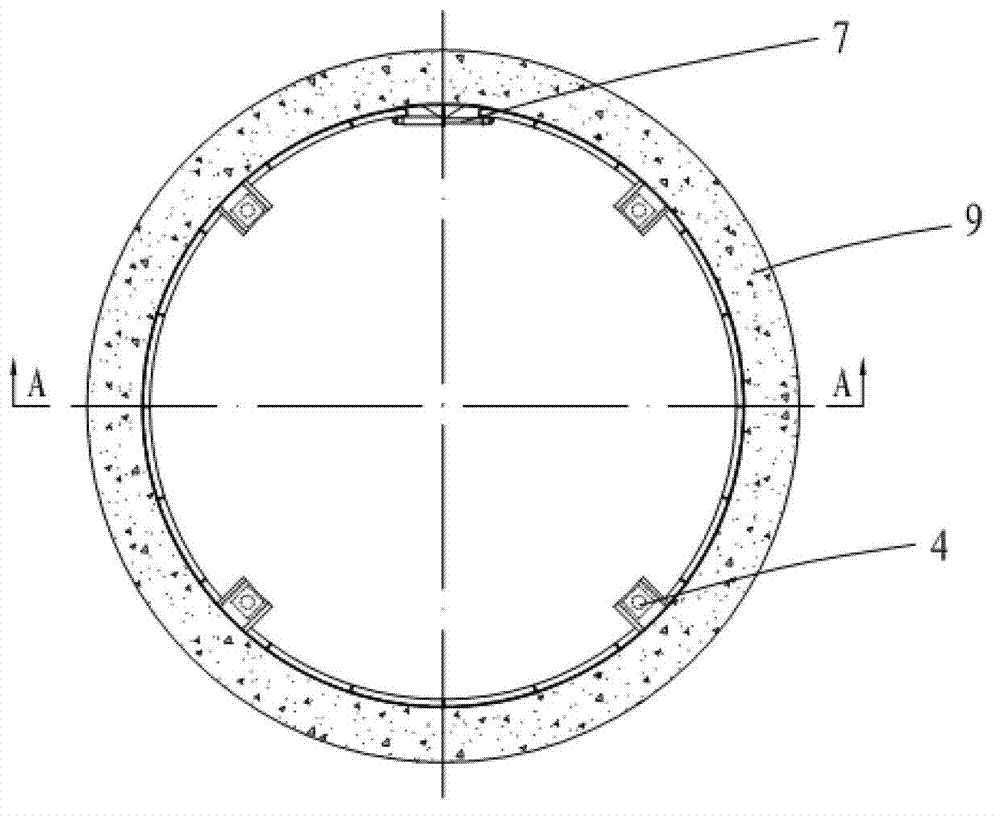

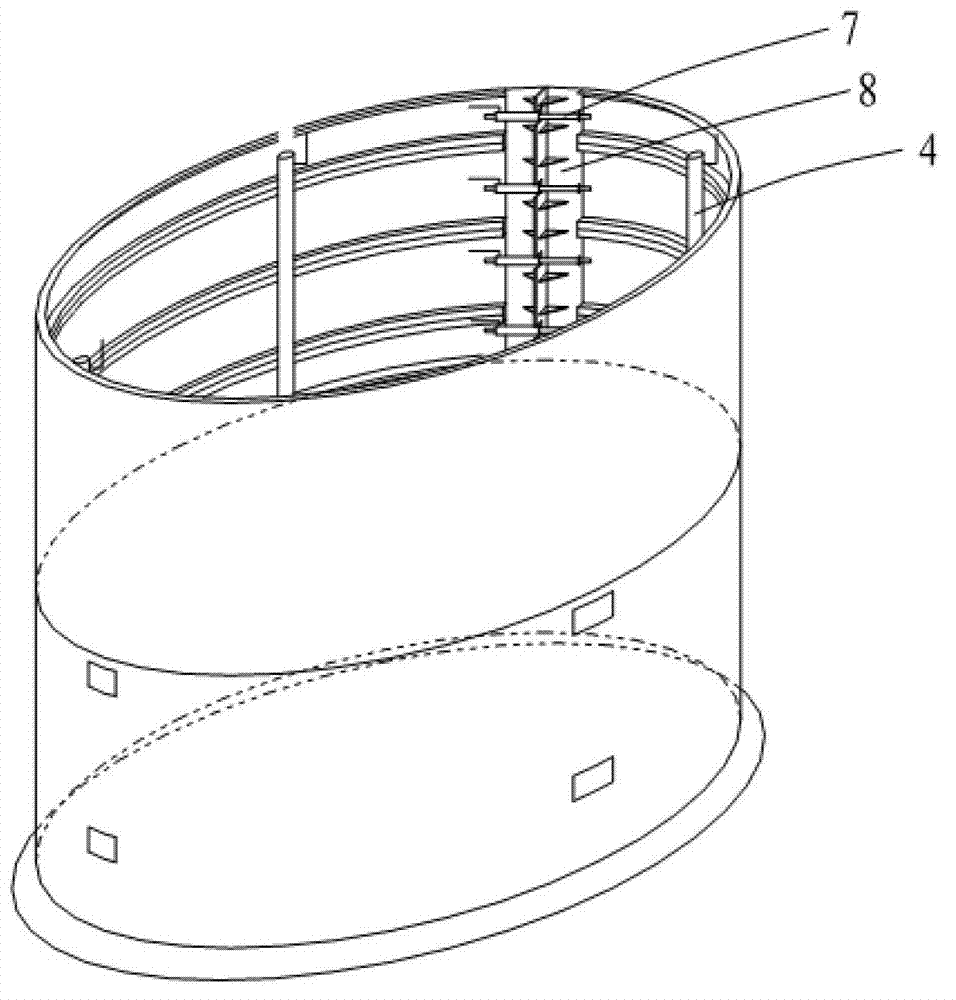

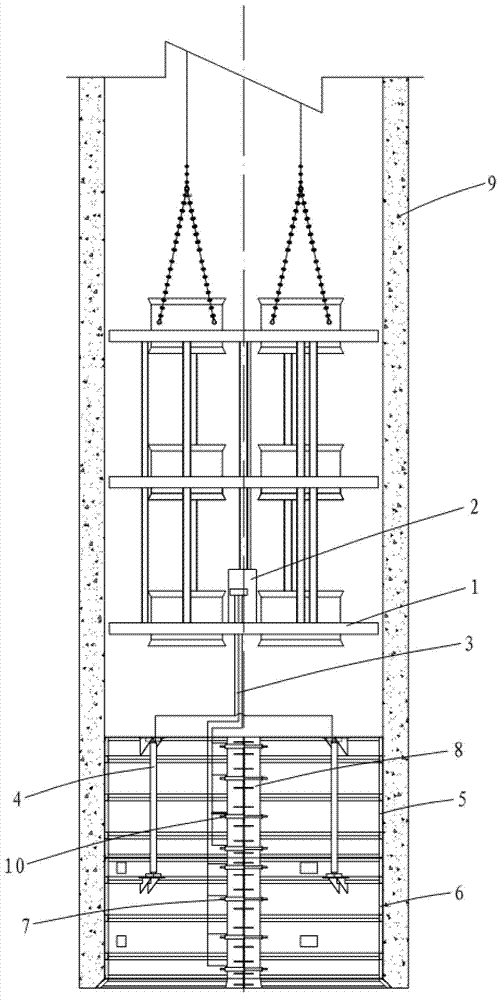

[0021] Example: Combine Figure 1-3 , the fully hydraulic self-moving formwork device for vertical shaft wall building of this embodiment, which includes:

[0022] Suspension pan 1 suspended in the vertical shaft and hydraulic station 2 set on the suspension pan 1, the hydraulic station is a working room, connected with the vertical cylinder 4, the first horizontal cylinder 11 and the second horizontal cylinder 7 through the high-pressure pipeline 3 , centralized control can be realized by operating the handle, and it can also be controlled separately, and a locking structure is provided to maintain a sufficient pressure to ensure that the frictional resistance between the support structure 5 and the well wall surrounds the well wall, and the mobile formwork 6 is suspended.

[0023] In the specific arrangement, the supporting structure 5 and the movable formwork 6 are arranged under the suspension pan, the supporting structure 5 is connected with the vertical oil cylinder 4, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com