Novel winding machine control system

A control system and winding machine technology, applied in electromechanical devices, manufacturing motor generators, electrical components, etc., can solve problems such as inability to achieve neat wiring, uncontrollable winding tension, affecting winding quality, etc., and it is easy to modify. and maintenance, improved winding quality, increased flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

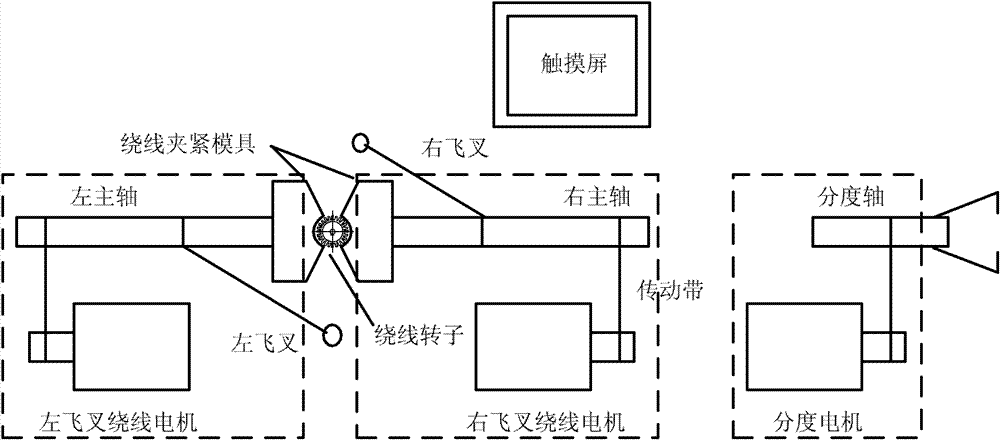

[0019] Such as figure 1 As shown, the two winding heads are respectively driven by the left and right motors, and the winding motor is driven to the winding main shaft through a synchronous belt. The two transmission boxes are fixed on the table through linear bearings, and the left and right movement of the transmission box is driven by the rough clamping cylinder and the fine clamping cylinder. The indexing motor is transmitted to the indexing shaft through the synchronous belt, and the clamping cylinder pushes the indexing shaft to make the collet clamp the rotor. The parallel cylinder pushes the hook line jacket, and cooperates with the indexing motor to realize the automatic hooking of the rotor commutator.

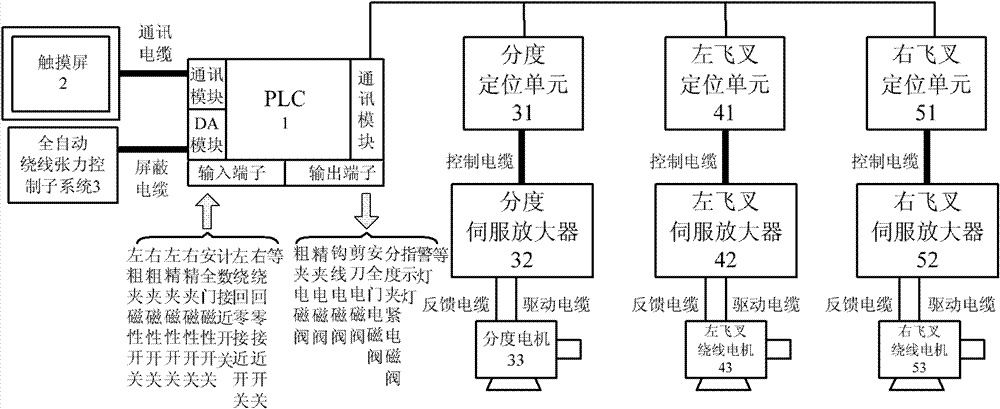

[0020] Such as figure 2 As shown, a new type of winding machine control system, including PLC1, touch screen 2, automatic winding tension control subsystem 3, indexing control subsystem, left flying fork control subsystem, right flying fork control subsystem, all ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com