Batch-wise operated retort using temporary storage of heat

A reaction tank and a temporary technology, applied in the field of processing systems, can solve problems such as production impact and the inability of equipment to complete production and processing, and achieve the effect of reducing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

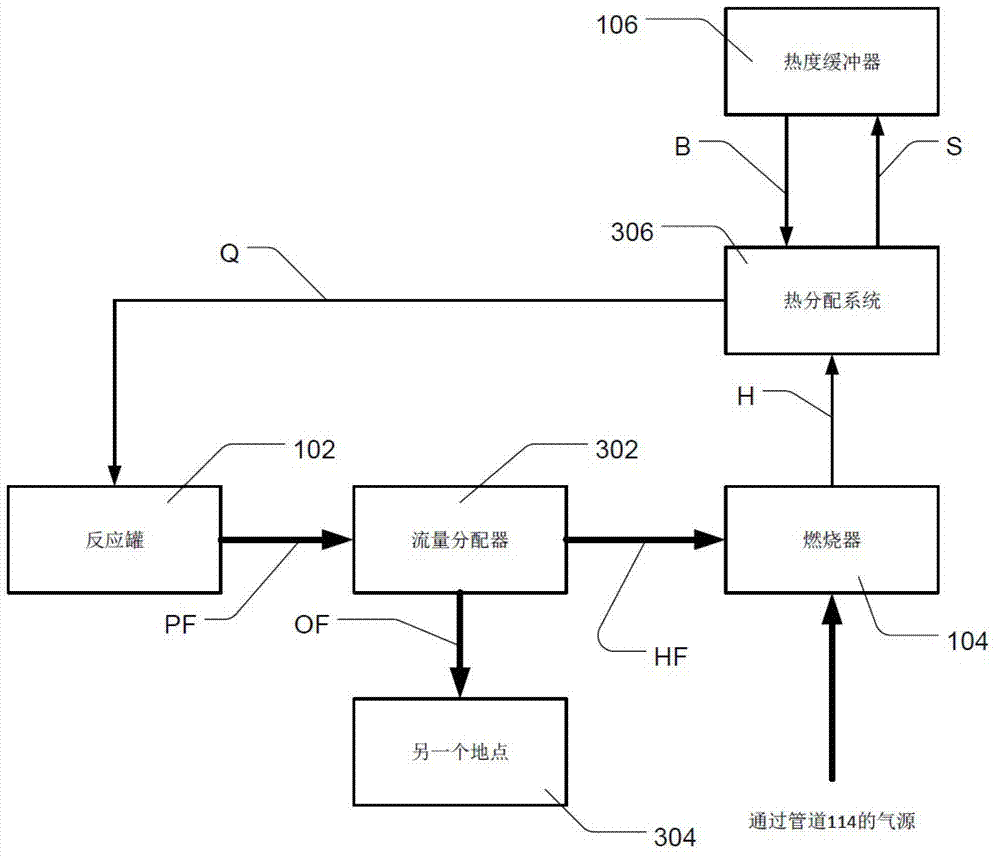

[0115] The invention relates to batch production and processing of processed objects, such as biomass energy, which is processed in batch reaction tanks by means of heating. In the process of producing and processing the processed object, the product fluid will be generated. The resultant fluid is combusted to generate heat. Depending on the progress of the production process, this part of the heat will be provided to the reaction tank or stored in a temporary heat storage.

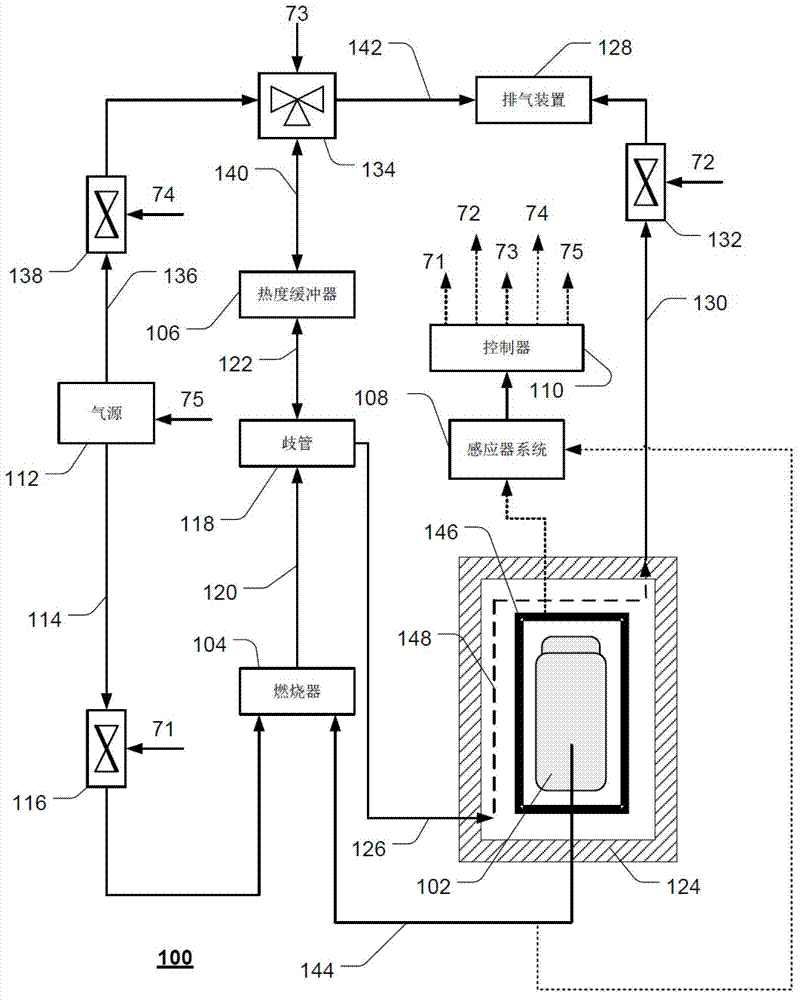

[0116] figure 1 This is the first embodiment of the processing system of the present invention for processing a workpiece. Production processing systems are designed to process workpieces in batches. In the process of producing and processing the processed object, the product fluid will be produced. The first embodiment 100 comprises a batch reactor vessel 102 which, in practice, is sealed with a gas-tight lid. The reaction tank 102 processes a single batch of processed objects in a batch processing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com