System for treatment of spraying organic waste gas by circulating liquid curtain

A technology of organic waste gas and treatment system, applied in coating, spraying device, using liquid separating agent, etc., can solve the problems of secondary pollution, waste gas treatment equipment cannot be used normally, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

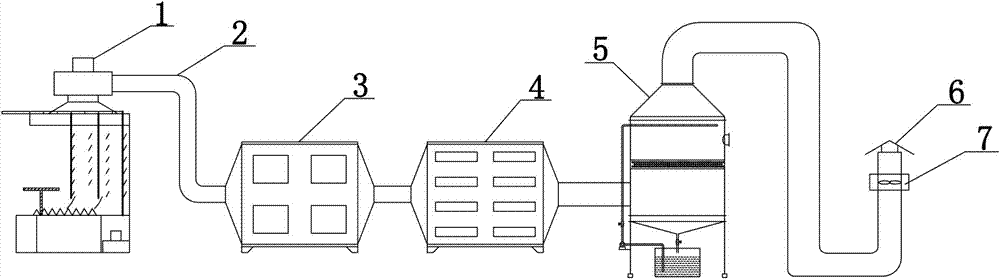

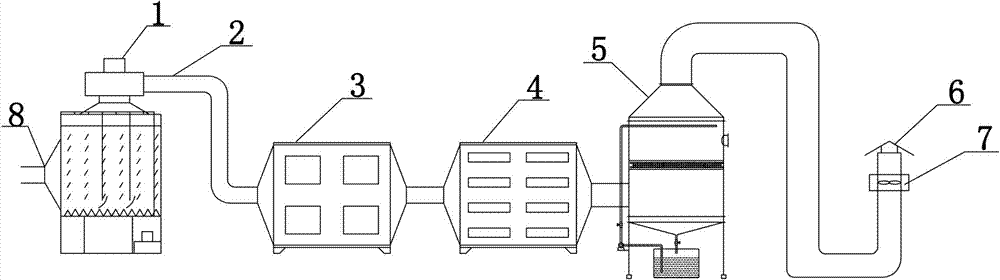

[0047] Refer to attached Figure 1-15 The circulating liquid curtain spraying organic waste gas treatment system includes a circulating liquid curtain spraying station 1, an organic waste gas low-temperature plasma and photocatalyst waste gas treatment device 3, an organic waste gas activated carbon treatment device 4 and a gas phase oxidation organic waste gas treatment device 5.

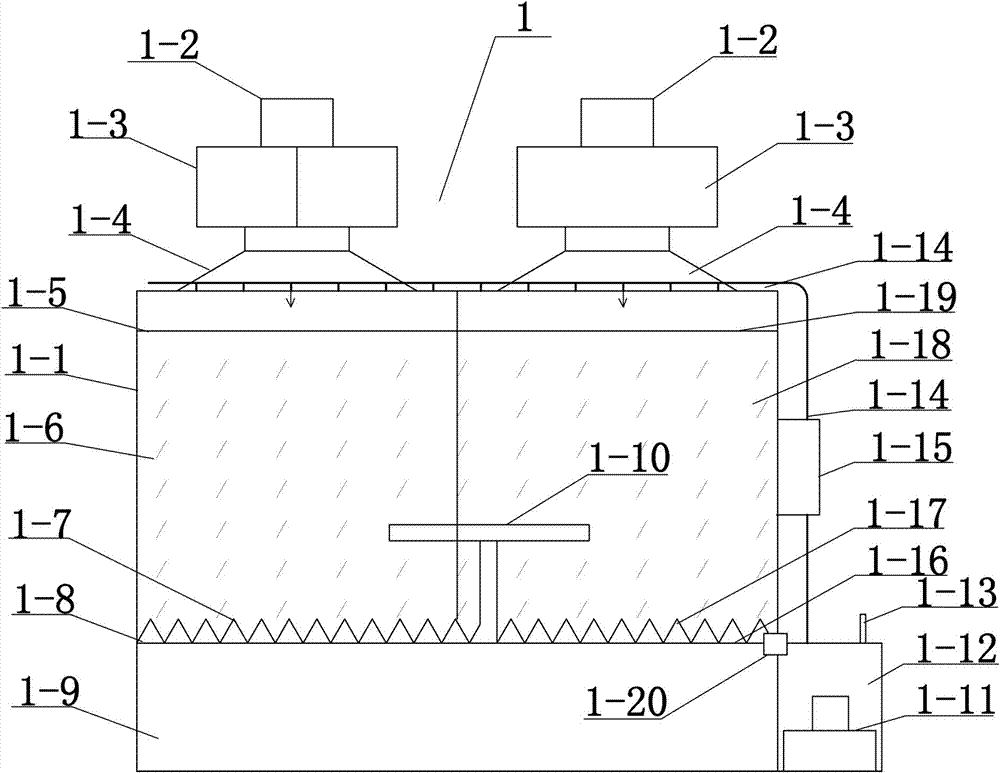

[0048] Circulating liquid curtain spraying station 1 includes box body 1-1, motor 1-2, fan 1-3, suction hood 1-4, overflow port 1-5, liquid curtain plate 1-6, toothed curtain Along one 1-7, deflector one 1-8, liquid tank 1-9, workbench 1-10, circulating liquid pump 1-11, liquid storage tank 1-12, liquid inlet 1-13, circulating liquid pipe 1-14, distribution box 1-15, deflector 2 1-16, toothed curtain 2 1-17, liquid curtain 2 1-18, overflow 2 1-19, liquid tank overflow 1 -20, liquid baffle plate 1-21, mesh replaceable isolation plate 1-22, cleaning port 1-23, circulating fluid tank 1-24, circula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com