Process for brewing yellow wine by adding seriflux

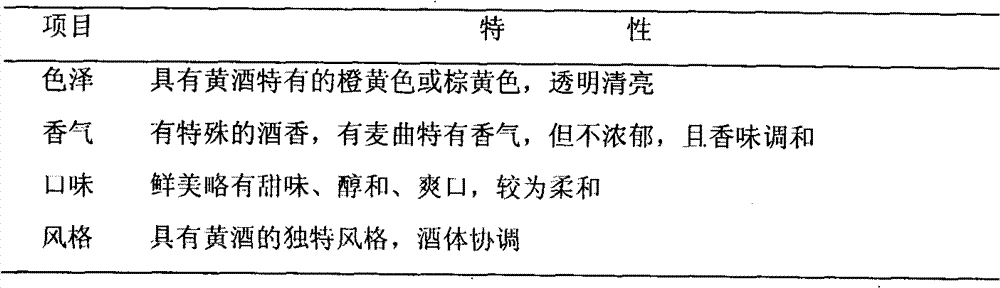

A technology and technology of yellow rice wine, applied in the field of fermentation and brewing, can solve the problems of rice soaking water corruption and odor, loss of rice nutrients, susceptibility to various miscellaneous bacteria, etc., to achieve rapid alcohol production, fast start of fermentation, and avoid miscellaneous bacteria pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

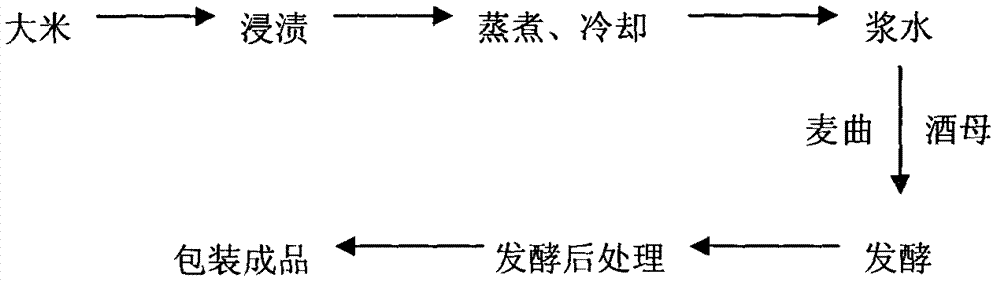

Method used

Image

Examples

Embodiment 1

[0015] Formula: 100% glutinous rice, 100% syrup, 15% wheat koji, 3% wine mother.

[0016] Process: Soak the glutinous rice at 20°C for 48 hours, then cook for 20 minutes after the steam completely penetrates the rice layer, let it cool, add 100% slurry water at 20°C, stir well, and control the temperature at 28±2°C. Add 15% of wheat koji and 3% of distiller's yeast, mix and ferment, carry out post-processing and pack the finished product to obtain yellow rice wine.

Embodiment 2

[0018] Formula: 100% japonica rice, 150% syrup, 18% wheat koji, 4% distiller's yeast.

[0019] Process: Soak the glutinous rice at 20°C for 60 hours, then cook for 40 minutes after the steam completely penetrates the rice layer, let it cool, add 150% slurry water at 20°C, stir well, and control the temperature at 28±2°C. Add 18% of wheat koji and 4% of distiller's yeast, mix evenly, ferment, carry out post-processing and pack the finished product to obtain yellow rice wine.

Embodiment 3

[0021] Recipe: 100% indica rice, 200% syrup, 20% wheat koji, 5% wine mother.

[0022] Process: Soak the glutinous rice at 20°C for 72 hours, then cook for 60 minutes after the steam completely penetrates the rice layer, let it cool, add 200% slurry water at 20°C, stir well, and control the temperature at 28±2°C. Add 20% wheat koji, 5% distiller's mother, mix evenly, ferment, carry out post-processing and pack the finished product to obtain yellow rice wine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com