Heat treatment method for obtaining two-way shape memory effect of SMA (Shape Memory Alloy) material

A heat treatment method and memory effect technology, applied in the field of heat treatment, can solve the problems of complex and time-consuming training process, limited two-way shape memory effect, shrinking recovery strain, etc., and achieve the effect of simple steps, compact size and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

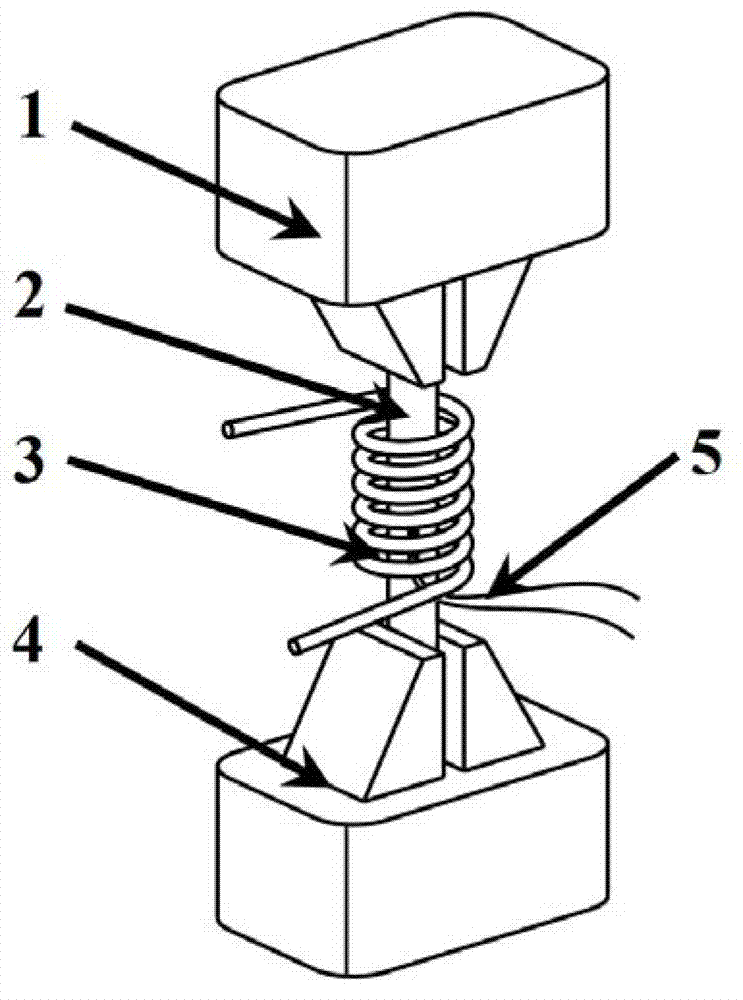

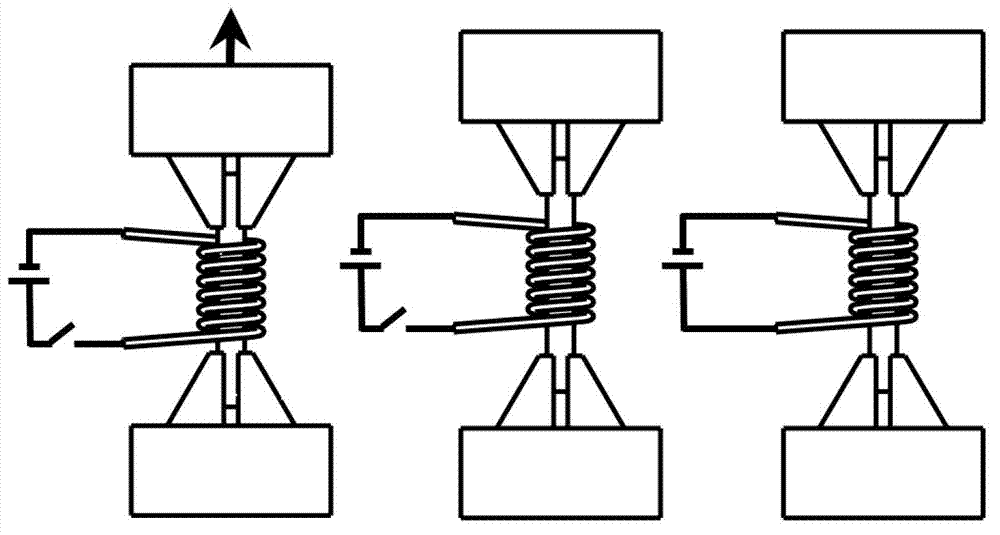

[0023] The heat treatment method of the two-way memory effect of the SMA material of the present invention is realized in this way, including mechanically loading the SMA material and restraining the shape, and then performing high-frequency electric induction heat treatment, which is special in that mechanical loading, restraint and high-frequency electric The induction heat treatment steps are as follows:

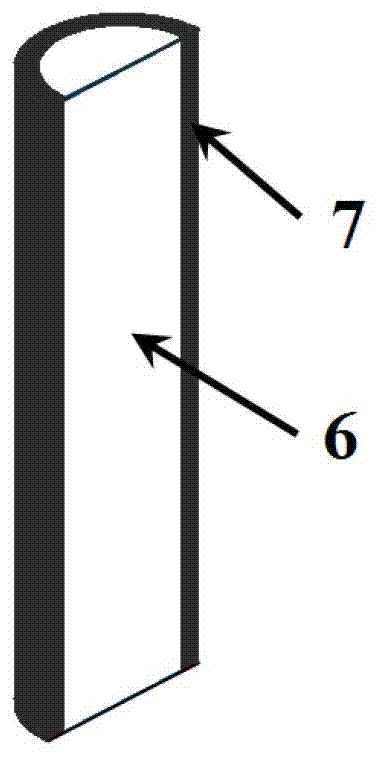

[0024] The first step: Stretch, bend or twist the SMA material (it can be a bar or plate) through a material testing machine to ensure that the shape after stretching, bending or twisting is the shape of the low-temperature state of the two-way memory effect, and the drawing is completed. After stretching, bending or torsion loading, keep restraint, do not unload, and keep the deformed shape unchanged;

[0025] The purpose of this loading process ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com