Elastic superconducting magnet skeleton and manufacturing method thereof

A technology of superconducting magnets and skeletons, which is applied in the manufacture of superconducting magnets/coils, magnetic objects, inductors/transformers/magnets, etc. It can solve the problem of broken current leads of superconducting magnet coils and the inability to effectively relieve the internal stress of superconducting coils and skeletons , superconducting tape breakage and other problems, to reduce the risk of magnet damage, avoid the effect of thermal expansion and contraction, and enhance the effect of low-temperature mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

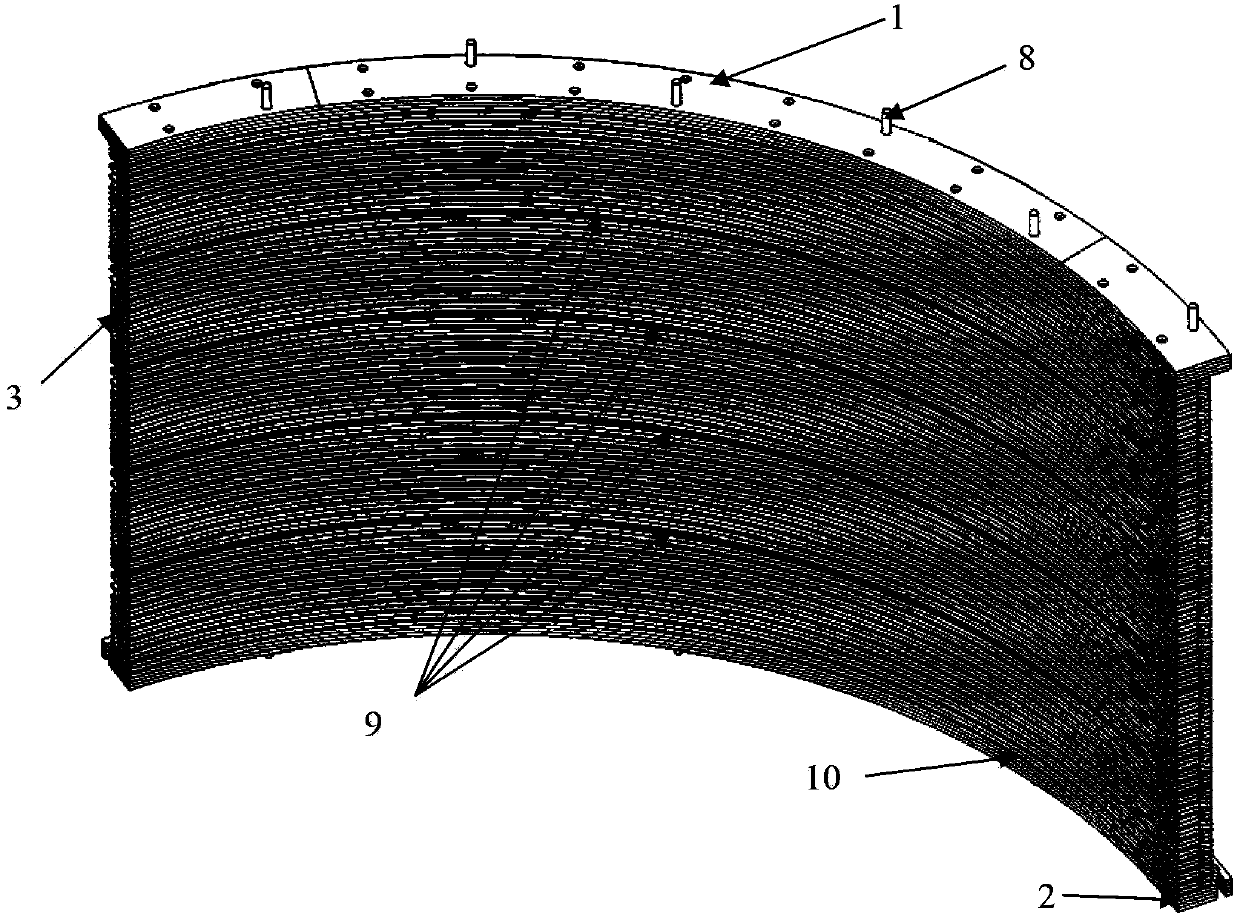

[0064] This embodiment uses the design principle of the present invention to design and process the superconducting magnet in the fault current limiter of 220kV superconducting saturated iron core. 2016mm, the outer diameter of the upper and lower pressure plates is 2070mm, and each layer is divided into six equal parts.

[0065] The magnet is 5 groups of coils connected in parallel, and each group of coils is connected in series by 9 double pie coils. Overall dimensions: height 930mm, outer diameter 2082mm (including the outer dimensions of the current leads).

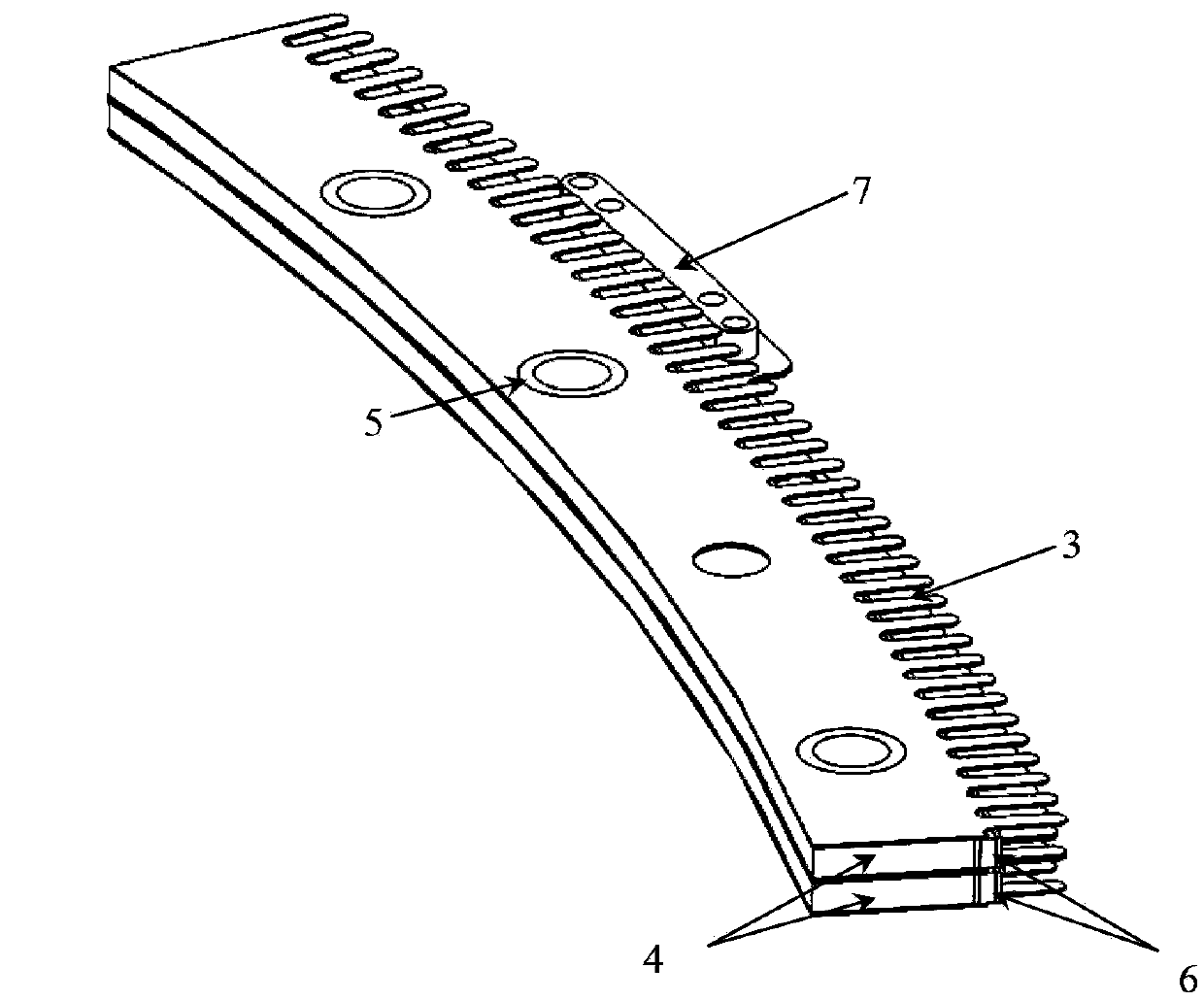

[0066] Its structure is as Figure 10 As shown, 1 and 5 are the side partitions; 3 is the middle partition composed of partitions, terminal partitions and transition partitions, which can be processed with 1mm epoxy resin board; 2 and 4 are superconducting wires The winding groove plate layer is processed by 6mm epoxy resin board; the low temperature elastic liner layer is 6mm thick and 5mm thick, and this layer use...

Embodiment 2

[0069] Such as Figure 11 As shown, in order to increase the heat exchange space between the superconducting wire and liquid nitrogen, an epoxy resin gasket 10 with a thickness of 3 mm (for heat dissipation gasket) is added between every two double-cake coils during the superconducting coil stacking process , so that the superconducting wire in each double-cake skeleton is completely exposed to liquid nitrogen, and the heat exchange efficiency between the wire and liquid nitrogen is improved.

Embodiment 3

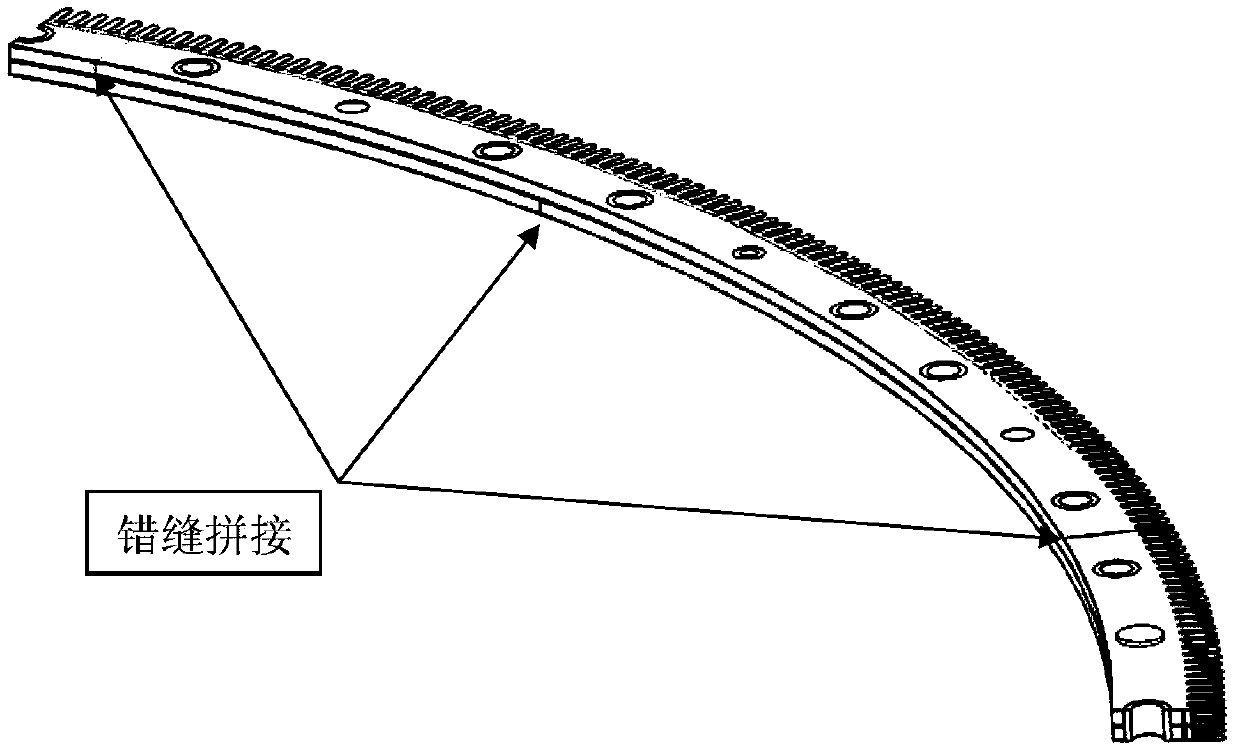

[0071] The superconducting magnet adopts multiple sets of coils connected in parallel, and the two adjacent double pie coils of the two sets of coils 100 and 200 will bear the overall pressure drop of the magnet, so this part needs to be additionally strengthened. Such as Figure 12 As shown, in order to increase the overall withstand voltage strength of the superconducting magnet, an insulating layer 9 is added between each group of superconducting coils. Group insulation layer size: inner diameter 1920mm, outer diameter 2070mm.

[0072] Stack all the double-cake superconducting coils upwards from the lower platen, and stack the heat dissipation gaskets and group insulating layer partitions according to the process requirements of the present invention. After all the double-cake superconducting coils are assembled, cover the upper platen, Use non-magnetic pull rods to pass through the pin ring holes of all fixed coil frames and the fixing holes of the upper and lower pressur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com