A Miniaturized Micromechanical Filter

A filter and micro-mechanical technology, applied in waveguide-type devices, chemical instruments and methods, instruments, etc., can solve the problems of large device volume, lower dielectric constant of substrates, etc., to reduce filter volume and achieve good consistency , the effect of reducing the volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

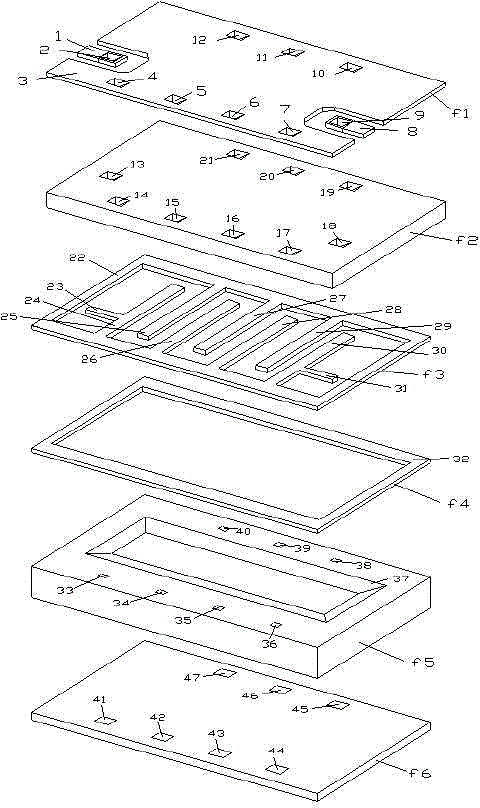

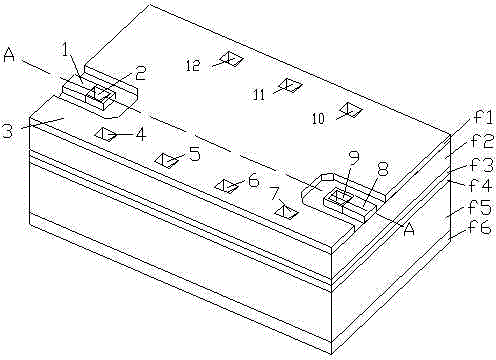

[0029] Below, with reference to the accompanying drawings, a preferred embodiment according to the present invention is provided to further describe the miniaturized micromechanical filter:

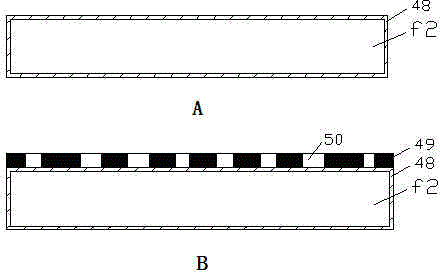

[0030] figure 1 It is a layered three-dimensional schematic diagram of a miniaturized micro-mechanical filter. The up-and-down direction referred to in the present invention is based on the direction in which the upper dielectric layer and the lower dielectric layer overlap in the vertical direction shown in the accompanying drawing, wherein f1 is the upper dielectric layer The metal layer on the upper surface of the layer, f2 is the upper dielectric layer, f3 is the metal electrode layer on the lower surface of the upper dielectric layer, f4 is the metal electrode layer on the upper surface of the lower dielectric layer, f5 is the lower dielectric layer, f6 is the metal layer on the lower surface of the lower dielectric layer, 1 and 8 are input and output signal lines, 2 and 9 are the th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com