Mold and its manufacturing method

A manufacturing method and mold technology, applied in coatings, instruments, optics, etc., can solve the problems of cracks in the coating layer, poor joints, hindering the flow of resin, etc., to improve surface roughness, reduce flexural deformation, fluidity, etc. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

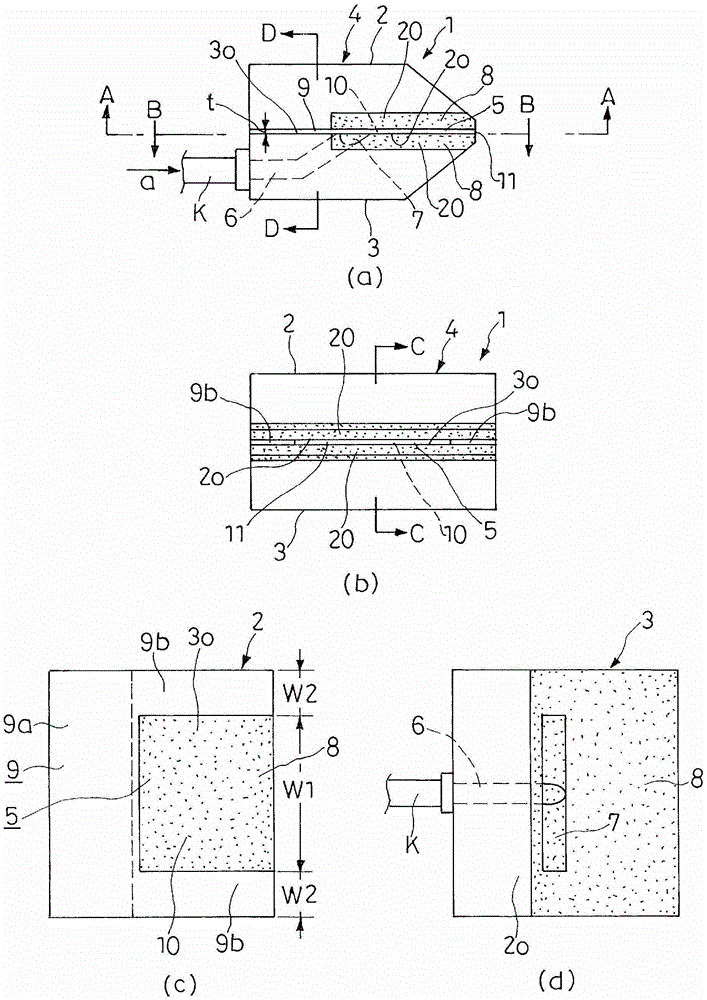

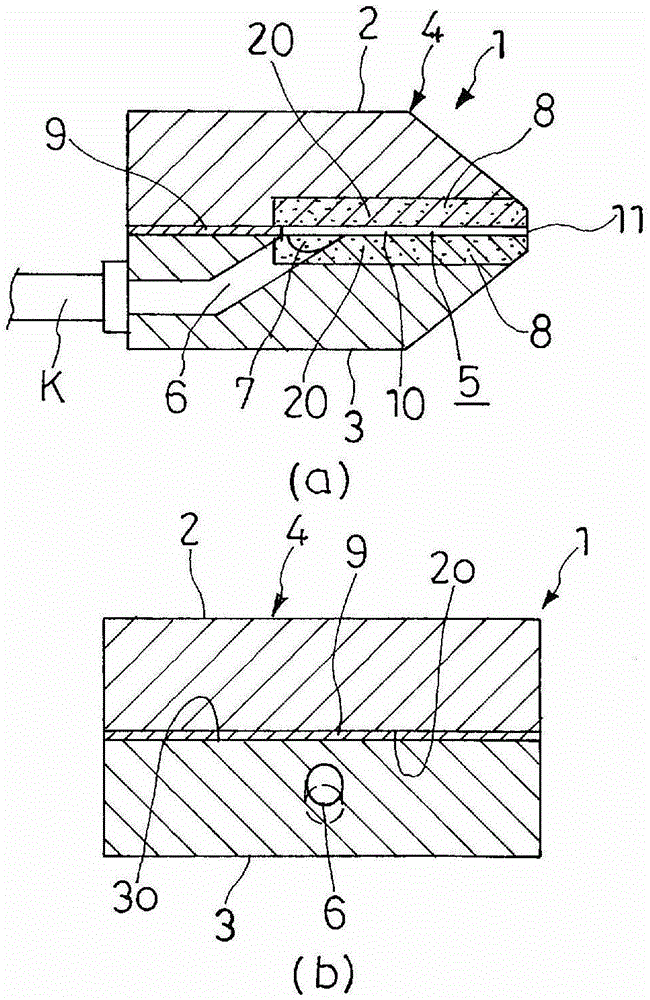

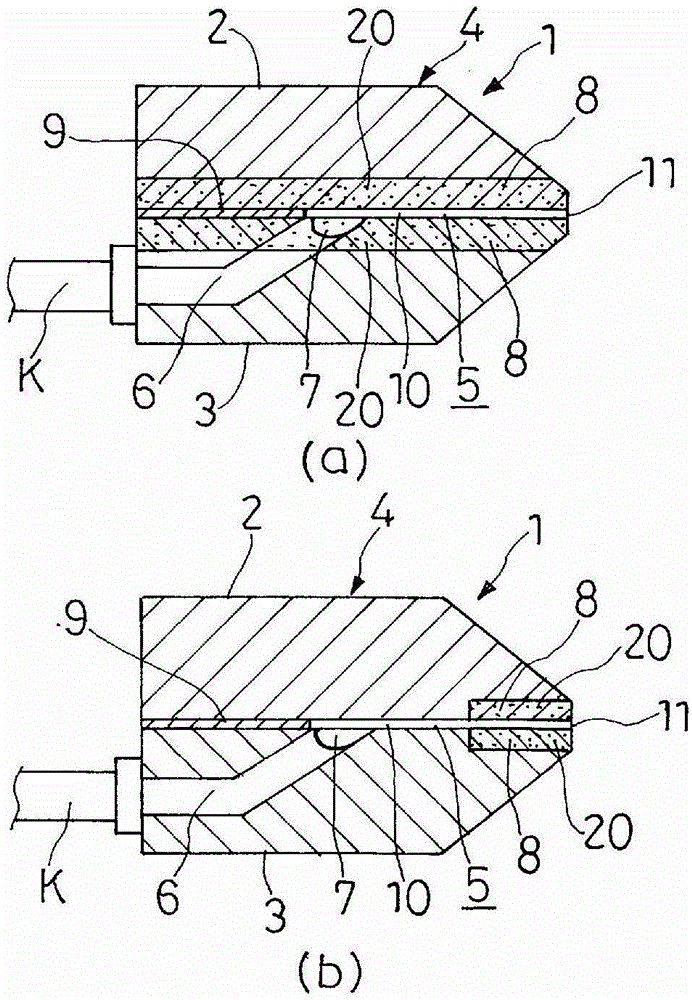

[0074] Hereinafter, a suitable embodiment of the present invention will be described according to the drawings, such as figure 1 As shown, the coating mold 1 has a mold body 4 composed of an upper mold 2 and a lower mold 3 , and a mold flow path 5 is provided between the upper and lower molds 2 and 3 . In the lower mold 3, as shown in (a) and (b) of Figure 1, the coating liquid supply path 6 that supplies the coating liquid from the outside through the supply pipe K and is supplied according to the arrow a; Once the coating liquid in the channel 6 is accumulated, a manifold 7 that expands in the mold width direction is provided. These supply paths 6 and manifolds 7 form part of the mold flow path 5 , and lip portions 8 , 8 are provided on the front end side of the mold flow path 5 .

[0075] In addition, on the joint surfaces 2o, 3o between the upper mold 2 and the lower mold 3, a base 9a, two sleeves 9b, 9b forms the inner tube 9 with a substantially U-shaped thickness t in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com