Photosensitive resin composition, printing plate precursor, and flexographic printing plate

A technology of photosensitive resin and composition, applied in printing, printing plate, printing process and other directions, can solve the problems of not satisfying water developability, dryness and image reproducibility at the same time, time-consuming development process, low image reproducibility, etc. Achieve the effects of excellent image reproducibility, excellent image reproducibility, and excellent image reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

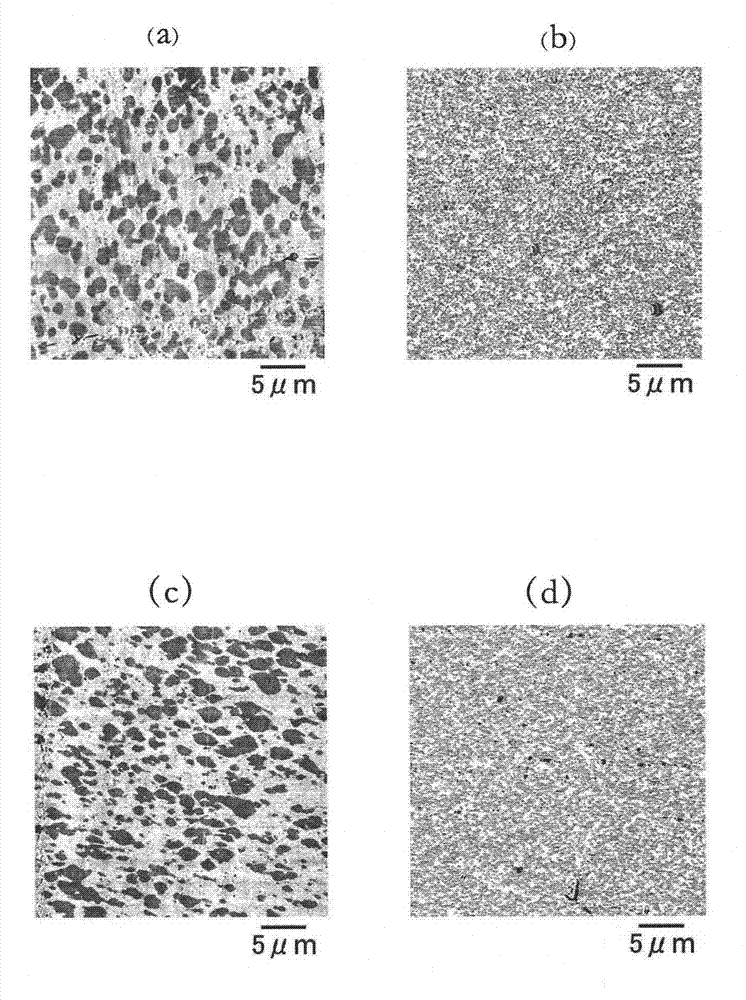

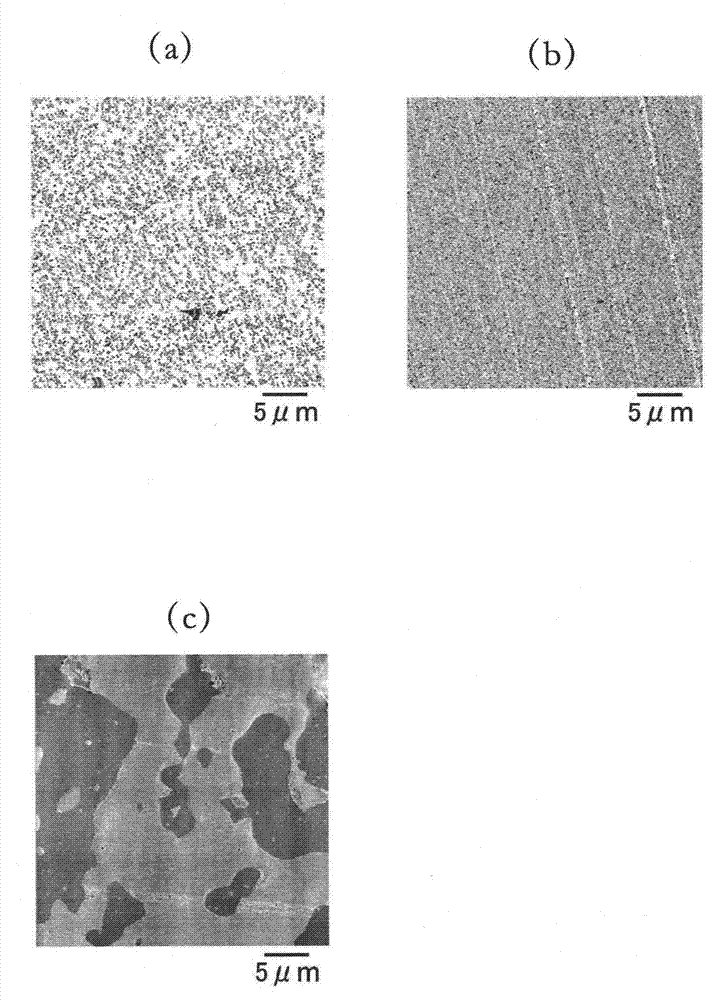

Image

Examples

Embodiment 1

[0090]

[0091] 45.5 parts by mass of water-dispersible latex (25 parts by mass of solid polymer), 15 parts by mass of acrylic modified liquid BR, and 5 parts by mass of acrylic monomer were mixed, heated at 120° C. to evaporate water in a dryer In 2 hours, a mixture of the polymer obtained from the water-dispersible latex and the photopolymerizable monomer was obtained. This mixture was kneaded with 30 parts by mass of NBR and 2 parts by mass of surfactant in a kneader for 45 minutes. Then, 0.2 part by mass of a thermal polymerization inhibitor, 1 part by mass of a photopolymerization initiator, and 0.03 part by mass of an ultraviolet absorber were added to the kneader, and kneaded for 5 minutes to obtain the photosensitive resin composition of Example 1 .

[0092]

[0093] The photosensitive resin composition obtained above was sandwiched between a 125 μm thick PET film substrate pre-coated with an adhesive on one side and a 100 μm thick PET film protective film pre-coa...

Embodiment 2~11

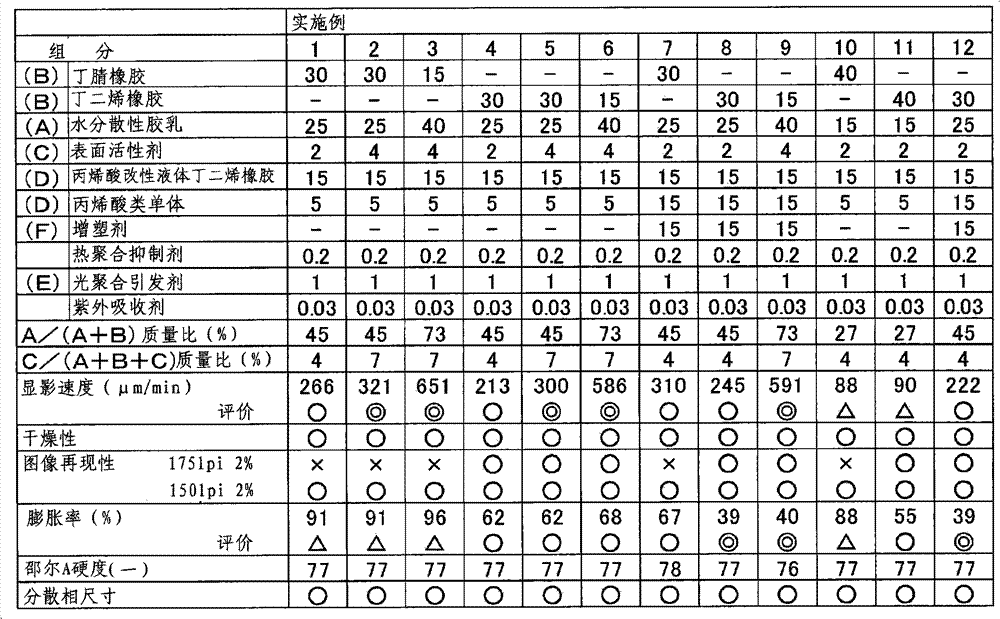

[0096] (Examples 2 to 11, Comparative Examples 1 to 4)

[0097] From the components shown in Table 1 or Table 2, a photosensitive resin composition was prepared in the same manner as in Example 1, and then, a printing plate precursor and a flexographic printing plate were prepared in the same manner as in Example 1.

Embodiment 12

[0101]

[0102] Using the components shown in Table 1, the photosensitive resin composition of Example 12 was prepared in the same manner as in Example 1.

[0103]

[0104] Using blade stirring, 28.8 parts by mass of carbon black (manufactured by Mitsubishi Chemical Co., Ltd., trade name: MA8), 28.8 parts by mass of acrylic resin (manufactured by Negami Kogyo Co., Ltd., trade name: ハイパ一ル M4501) and 4.5 parts by mass 105.2 parts by mass of methyl isobutyl ketone was mixed with 105.2 parts by mass of a plasticizer (manufactured by Wako Pure Chemical Industries, Ltd., acetyl tributyl citrate). The obtained liquid mixture was dispersed with a triple roll mill, and methyl isobutyl ketone in a solid state of 15% by mass was added to obtain a coating material. Then, it was coated on a 100-μm-thick PET film with a dry coating film thickness of 2 μm using a bar coater, and dried at 120° C. for 5 minutes to obtain an infrared ablation layer / protective film laminate structure.

[01...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com