LabView-based real-time monitoring system for laser cladding/laser re-melting process temperature field

A real-time monitoring system, laser remelting technology, applied in laser welding equipment, coating, metal material coating technology, etc., can solve the problems of incapable of real-time measurement of the processing process, small temperature measurement range, expensive price, etc., to meet the overall requirements View the requirements and details, meet the needs of different conditions, and have strong openness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

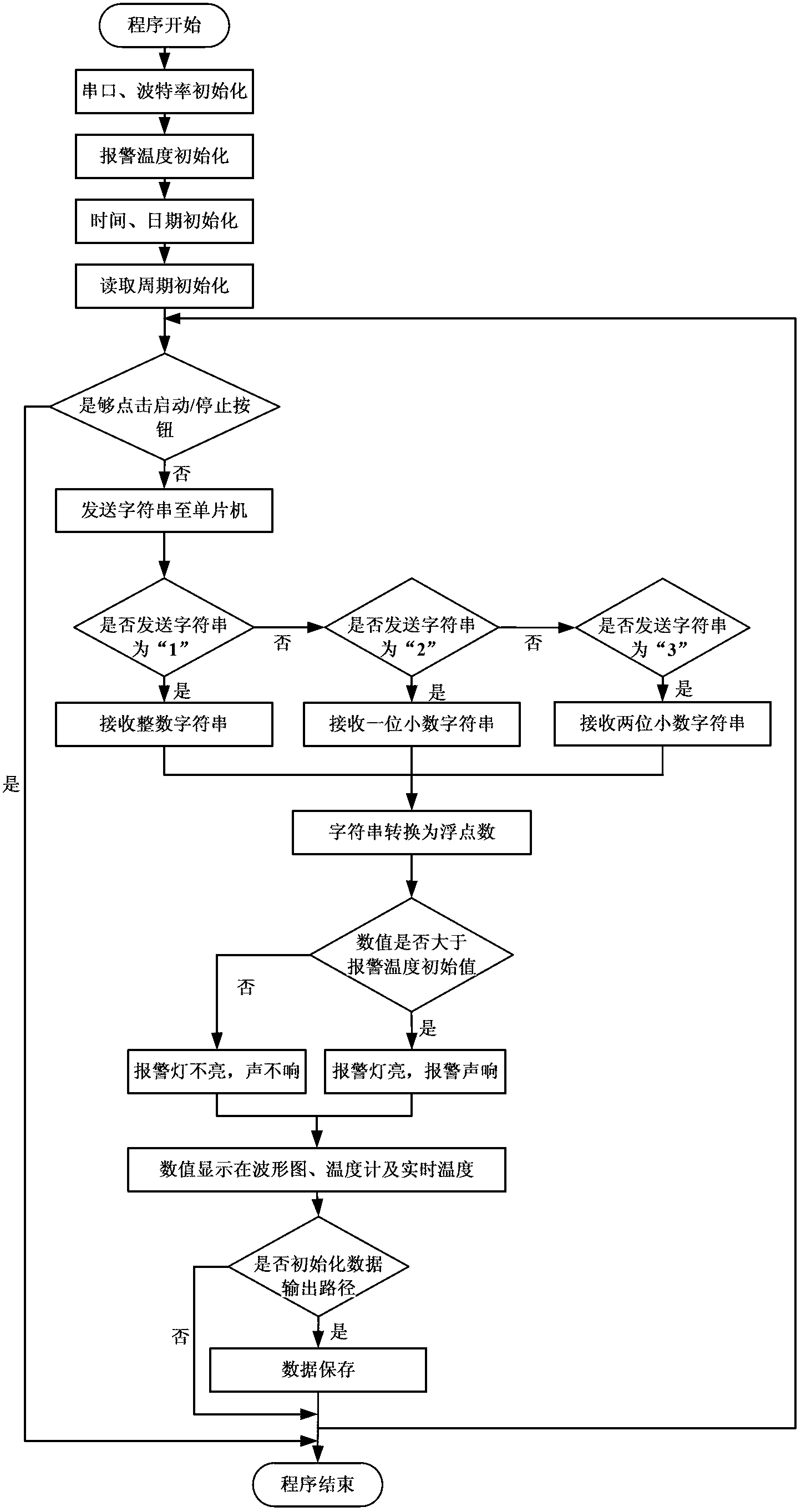

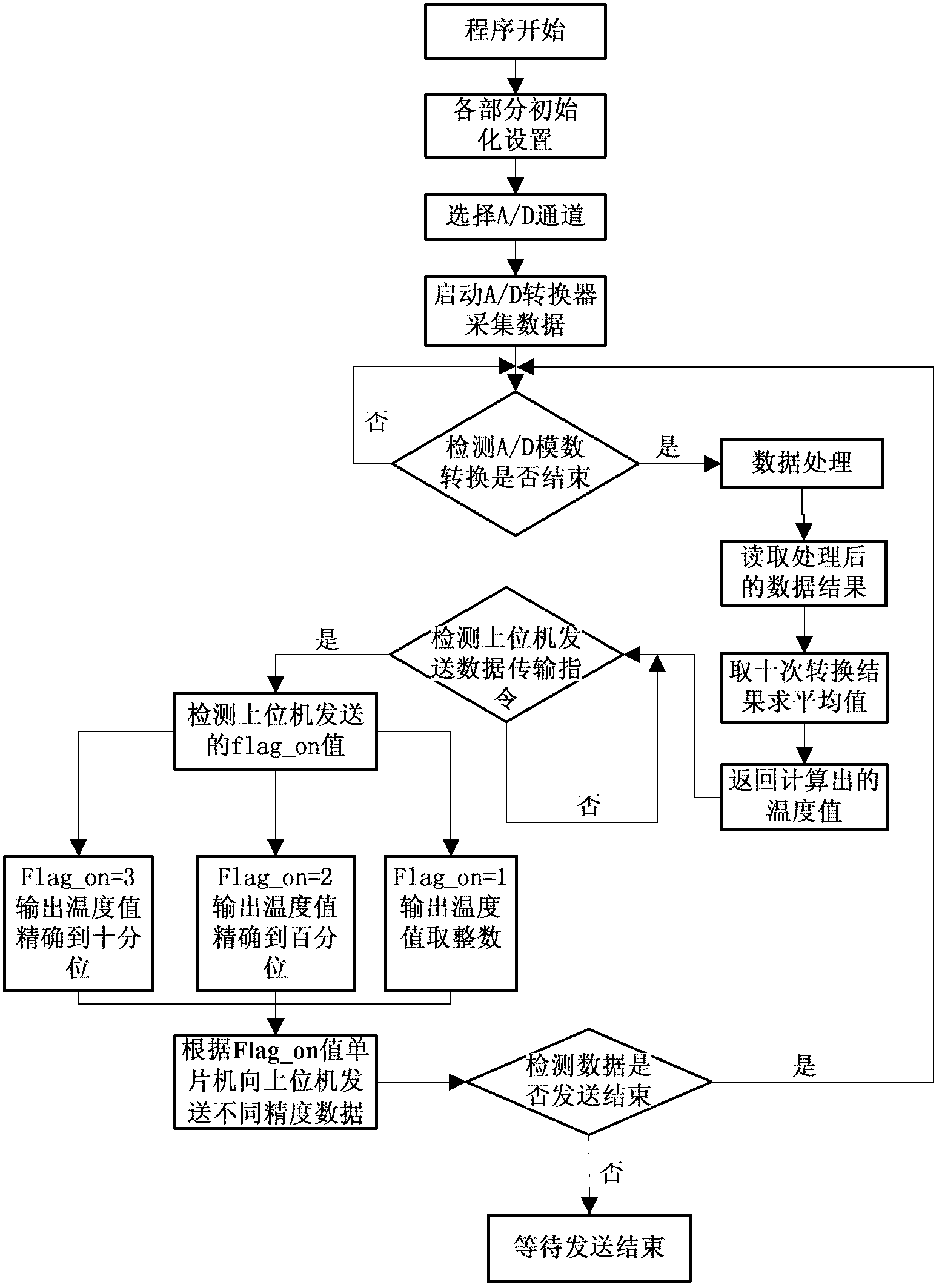

[0046] The real-time monitoring system of the temperature field in the laser cladding / laser remelting process based on LabView is mainly composed of a software control part and a temperature measurement device. The software control part is composed of a LabView program and a single-chip microcomputer program.

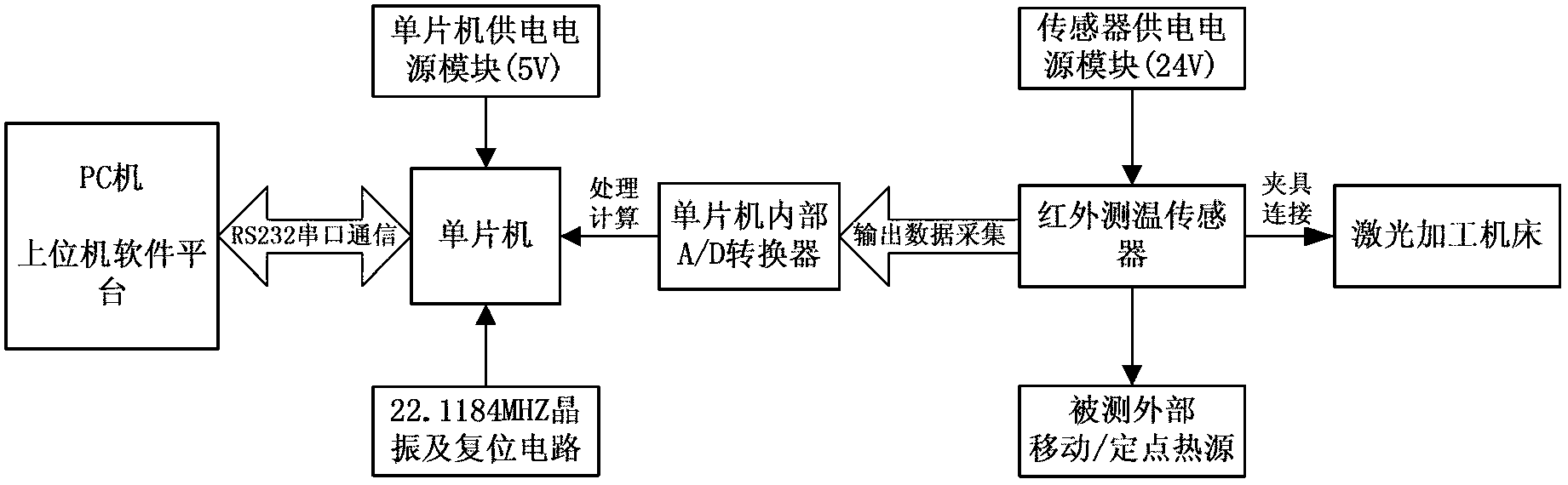

[0047] Such as figure 1 As shown, the temperature measuring device includes an infrared temperature measuring sensor, a single-chip microcomputer, a single-chip power supply module, a sensor power supply module, a 22.1184MH crystal oscillator and a reset circuit. The infrared temperature measuring sensor is connected with the single-chip microcomputer through a line, the single-chip microcomputer is connected with the upper computer through the RS232 chip, the 24V power adapter is connected with the sensor, the 5V power supply adapter is connected with the single-chip microcomputer, and the infrared temperature measuring sensor is fixed on the main shaft of the laser pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com