Integrated cage-type denitrification reactor

A reactor and denitrification technology, which is applied in the field of integrated cage denitrification reactor, can solve the problems of difficult regulation of substrate ratio, nitrite accumulation, limited process, etc., and achieve low degree of substrate self-inhibition and product inhibition, and overall High nitrogen removal rate and volume removal rate, good denitrification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

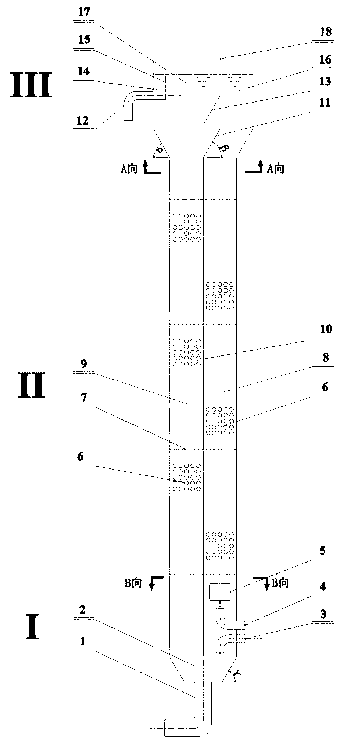

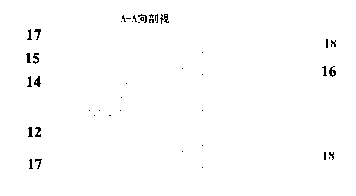

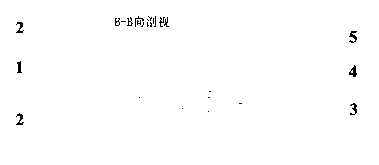

[0016] Such as figure 1 , 2 , 3, the integrated cage denitrification reactor is provided with water inlet zone I, reaction zone II and separation zone III from bottom to top; including sludge discharge pipe 1, water diversion zone 2, water inlet pipe 3, and air intake pipe 4. Aeration head 5, porous packing 6, perforated baffle 7, aerobic zone 8, anaerobic zone 9, first longitudinal partition 10, lower deflector 11, outlet pipe 12, upper deflector 13, overflow Groove 14 , overflow weir 15 , degassing zone 16 , settling zone 17 and second longitudinal septum 18 .

[0017] The reactor body is provided with a first longitudinal partition 10, the lower end of the first longitudinal partition 10 at the bottom of the water inlet area 1 is provided with a water flow diversion area 2, the bottom of the water flow diversion area 2 is provided with a mud discharge pipe 1, and the middle part of the water intake area I is provided with an inlet Water pipe 3 and air intake pipe 4, water...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com