High-strength die-casting aluminum alloy for pressure casting

A technology for casting aluminum alloys and aluminum alloys, which is applied in the field of die-casting aluminum alloys. Quantification and other issues, to achieve the effect of excellent casting performance, high hardness, good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

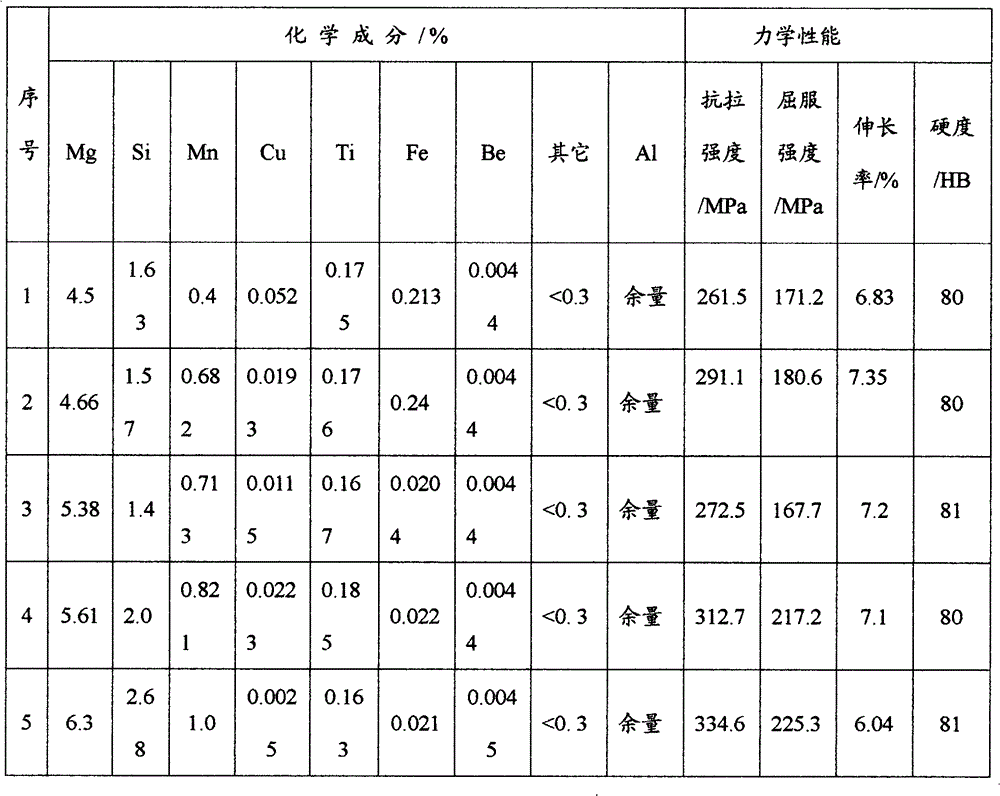

[0026] The Al-Mg-Si-Mn series die-casting aluminum alloy materials shown in Groups 1 to 5 were manufactured according to the recipes described in Table 1. Table 1 also includes the mechanical properties of each die-cast aluminum alloy material.

[0027] The preparation method of above-mentioned aluminum alloy material is:

[0028] The metal aluminum, silicon, manganese, titanium and beryllium of the proportioning ratio are added to the high Al 2 o 3 , low SiO 2 Melt in a graphite crucible furnace at a temperature of 973K-1023K, add Al-Be intermediate alloy after the molten aluminum is melted, and then refine by rotating argon blowing for 10-15min, then add metal magnesium, and heat up to 973K-1013K The slag removal and pouring are formed by vacuum die casting, the injection pressure is 60-70MPa, and the injection speed is 3.5-5.0m / s. According to the above smelting process and die-casting process parameters, the mechanical properties (tensile strength, yield strength, elon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com