Handheld insulative discharging combustible gas igniter

A hand-held, igniter technology, applied in the direction of combustion ignition, incandescent ignition, combustion methods, etc., can solve the problems of failure to ignite, reduce thermal insulation performance, unreliable ignition, etc., and achieve the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The specific embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

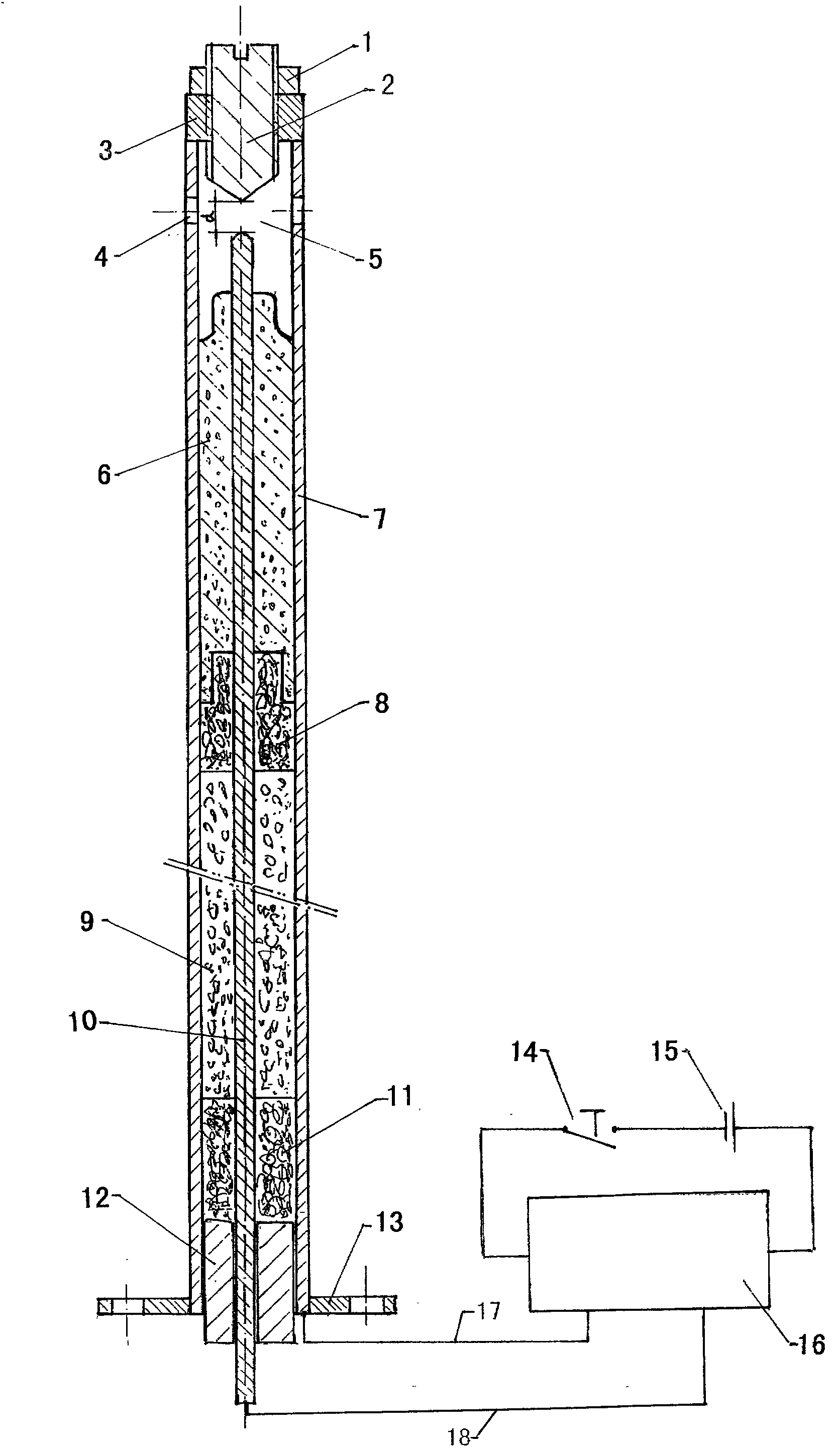

[0011] (Such as figure 1 As shown), a kind of hand-held insulating discharge type combustible gas igniter includes a splicing cap 1, a tip discharge electrode 2, a fastening nut 3, a positioning support tube 6, a round tube conductive wall 7, an upper sealing positioning layer 8, Insulation layer 9, core needle 10, lower sealing and positioning layer 11, core needle positioning insulating support column 12, connecting plate 13, operation button 14, battery 15, boost inverter module 16, first output line 17 and second output line 18, wherein the tip discharge electrode 2 is a full-section conical discharge electrode made of 304 stainless steel, the fastening nut 3 is a welded round head nut for discharge, and the positioning support tube 6 is a high-temperature ceramic tube glazed on the surface, which is resistant to dirt and its h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com