Cell assembly and battery system

A technology for battery systems and battery packs, applied in the field of battery systems, can solve the problems of increased interval, decreased battery capacity, increased internal resistance, etc., and achieves the effect of easy wiring and connection operation and compact assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] Hereinafter, embodiments of the present invention will be described with reference to the drawings. In addition, the same reference numerals are used for the same components, and detailed description thereof will be appropriately omitted.

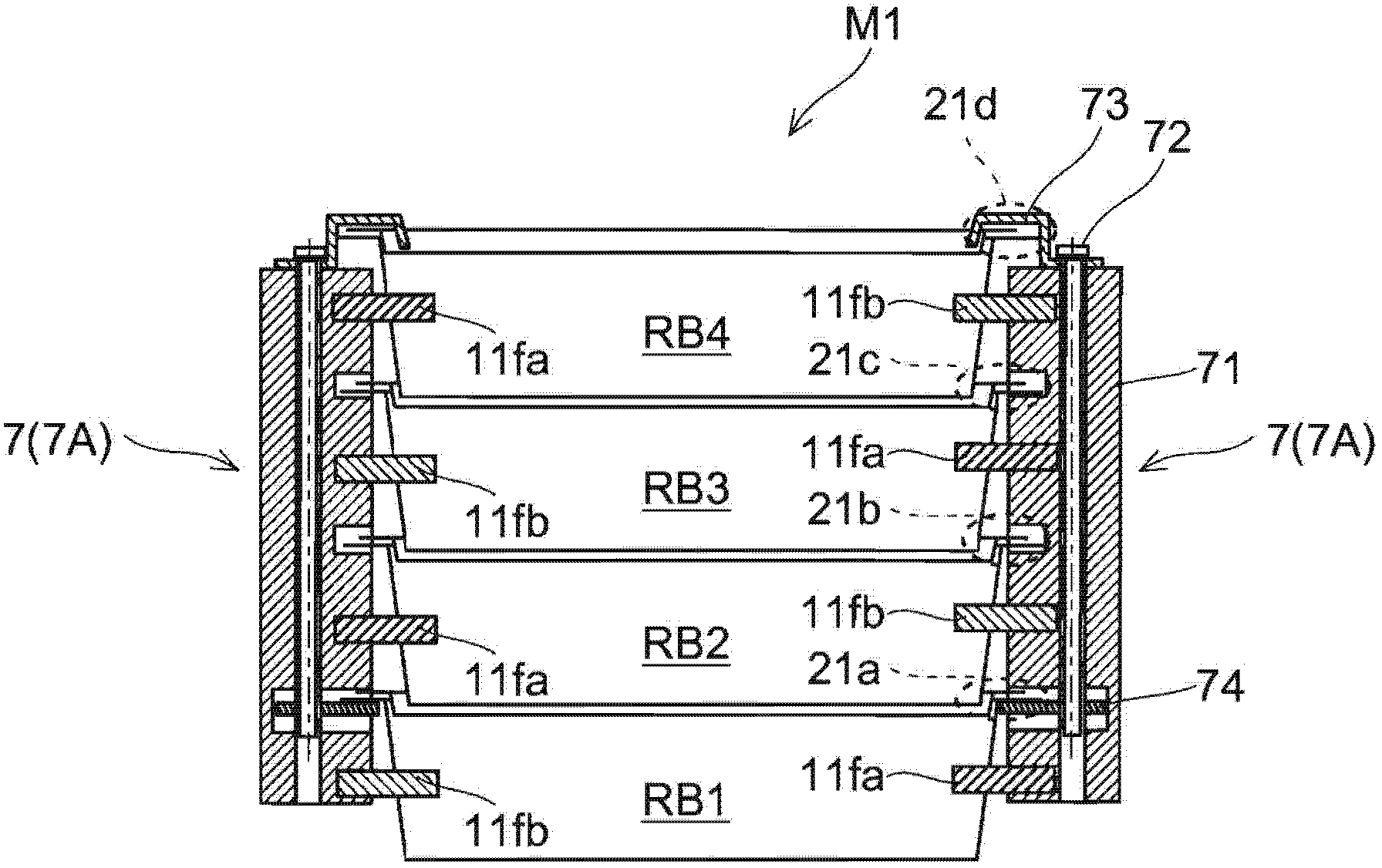

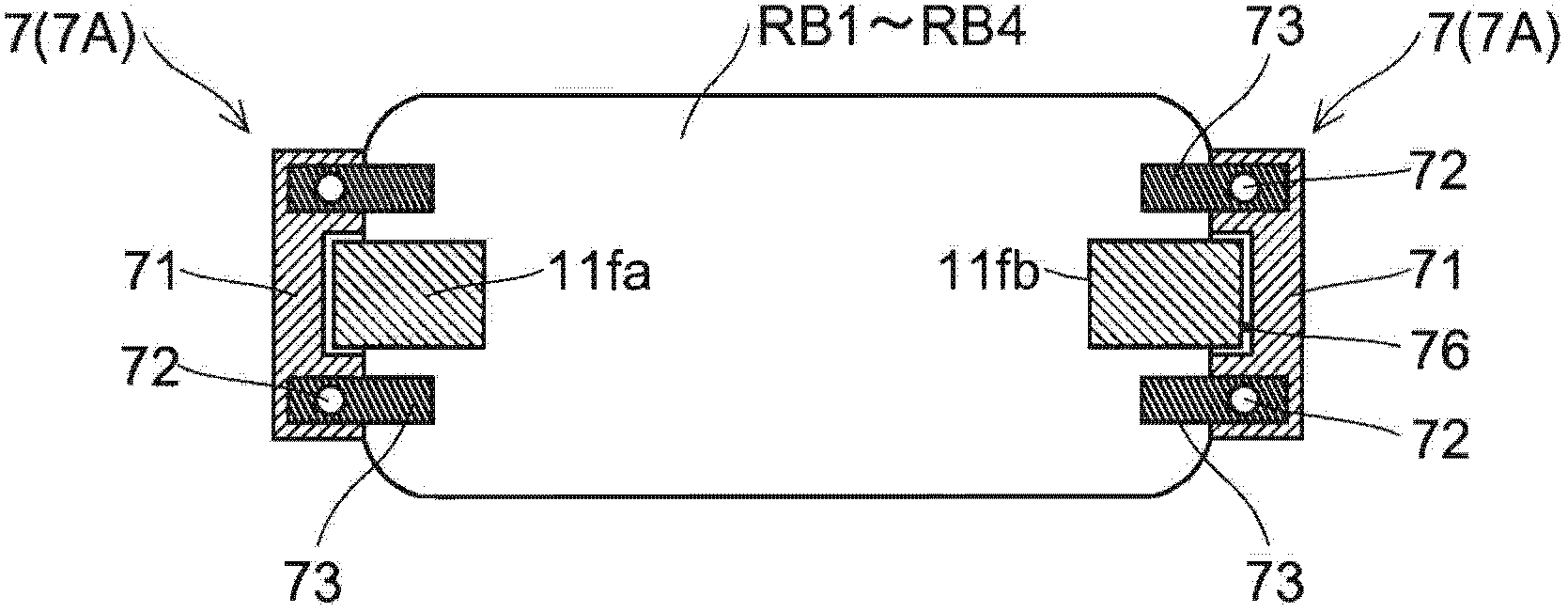

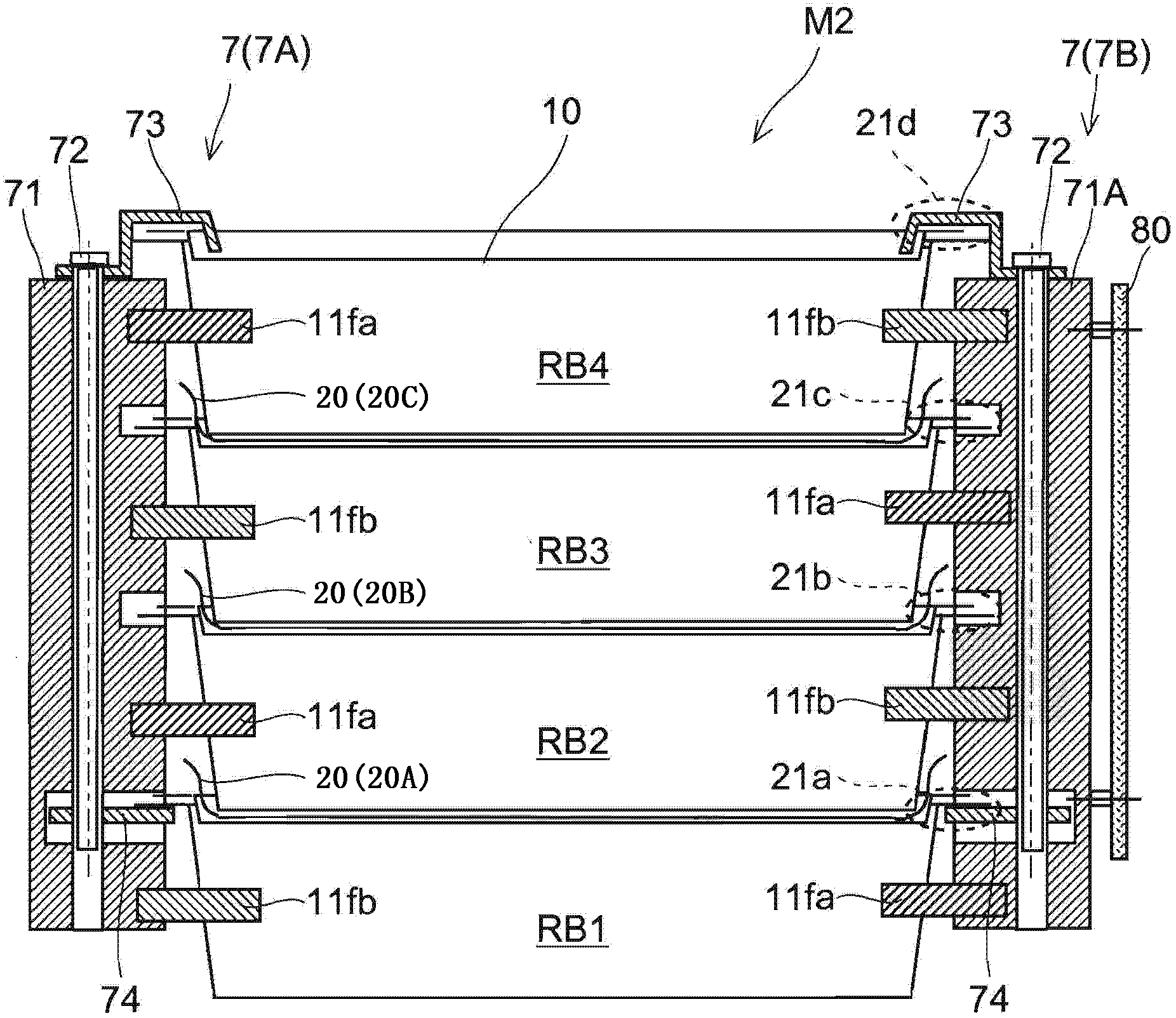

[0072] use figure 1 , figure 2 The battery pack M1 according to this embodiment will be described. figure 1 is a schematic cross-sectional view showing the overall structure of the assembled battery M1 of the first embodiment, figure 2 It is a rough plan view. The battery pack M1 is configured to exert a large battery capacity by connecting a plurality of single cells composed of laminated secondary batteries, such as figure 1 As shown, a plurality of, for example, four battery cells RB1 , RB2 , RB3 , and RB4 are stacked and integrally connected to form a battery pack M1 .

[0073] Furthermore, connecting members 7 ( 7A) are respectively inserted on both sides of the side on which the external terminals 11f ( 11fa , 11fb ) are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com