Self-humidifying fuel cell

A fuel cell and self-humidification technology, applied in fuel cells, fuel cell additives, circuits, etc., can solve problems such as differences in the performance of single cells, improve power density and energy density, improve stability, and reduce power consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

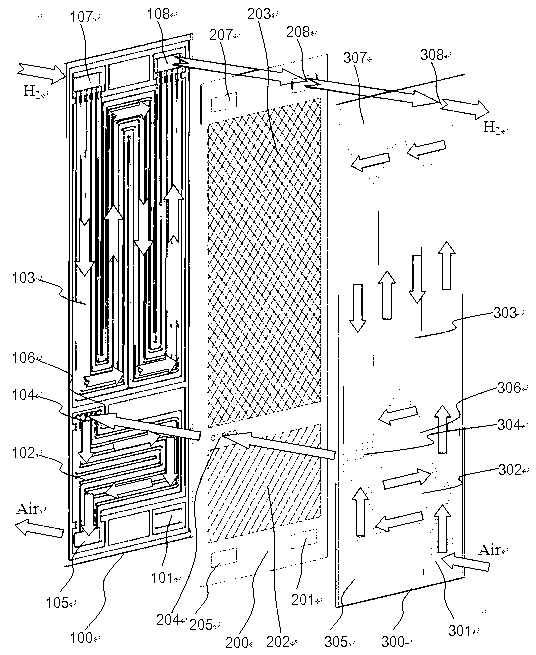

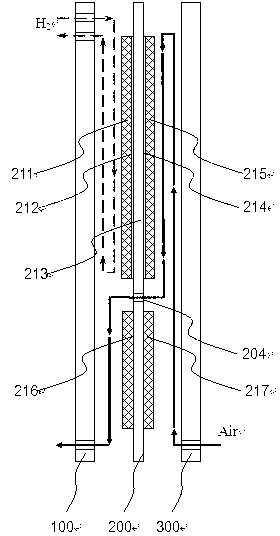

[0027] figure 1 with figure 2 An embodiment of a self-humidifying fuel cell of the present invention is shown in, figure 1 It is a schematic diagram of the three-dimensional decomposition structure of the fuel cell of the invention, figure 2 A schematic diagram of the side. from figure 1 It can be seen from the figure that the self-humidifying fuel cell is formed by stacking two fuel cell cells, and each fuel cell cell contains an anode flow field plate 100, a membrane electrode 200 and a cathode flow field plate 300 in sequence, and the lower part of the fuel cell cell It is the humidification part of the fuel cell, and the upper part is the reaction part of the fuel cell. The upper part of the membrane electrode 200 is provided with a hydrogen gas inlet hole 207 and a hydrogen gas exhaust hole 208 , and the lower part is provided with an air inlet hole 201 and an air exhaust hole 205 .

[0028] In the humidification zone 202 and the reaction zone 203 of the single mem...

Embodiment 2

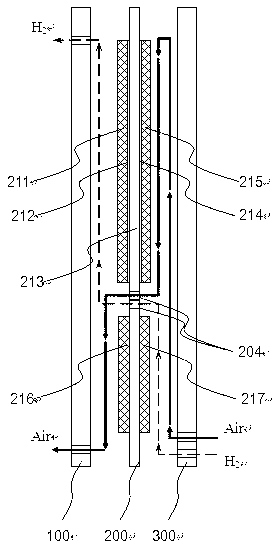

[0035] image 3 Shown is another embodiment, utilizing the air tail gas to simultaneously humidify the hydrogen and air intake. In this embodiment, the air flow mode is the same as that in the first embodiment, except that when hydrogen gas enters the single fuel cell, it first flows through the cathode humidification flow field 302 on the cathode flow field plate. At this time, the humidified flow field on the cathode flow field plate 300 is divided into two parts, one part is the air humidified flow field, and the other part is the hydrogen humidified flow field, and the air humidified flow field and the hydrogen humidified flow field pass through the cathode The seals 306 are separated from each other to prevent hydrogen and air from mixing with each other. The corresponding membrane electrode humidification area is also divided into two parts: hydrogen humidification area and air humidification area. After hydrogen enters the hydrogen humidification zone on the cathode f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com