Manufacturing method for embedding copper heat sink into circuit board

A technology of copper heat sink and manufacturing method, which is applied in the field of circuit board manufacturing, can solve problems such as low production capacity and difficulty in meeting mass production requirements, and achieve the effects of reducing manpower, facilitating inlay operations, and small bending deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

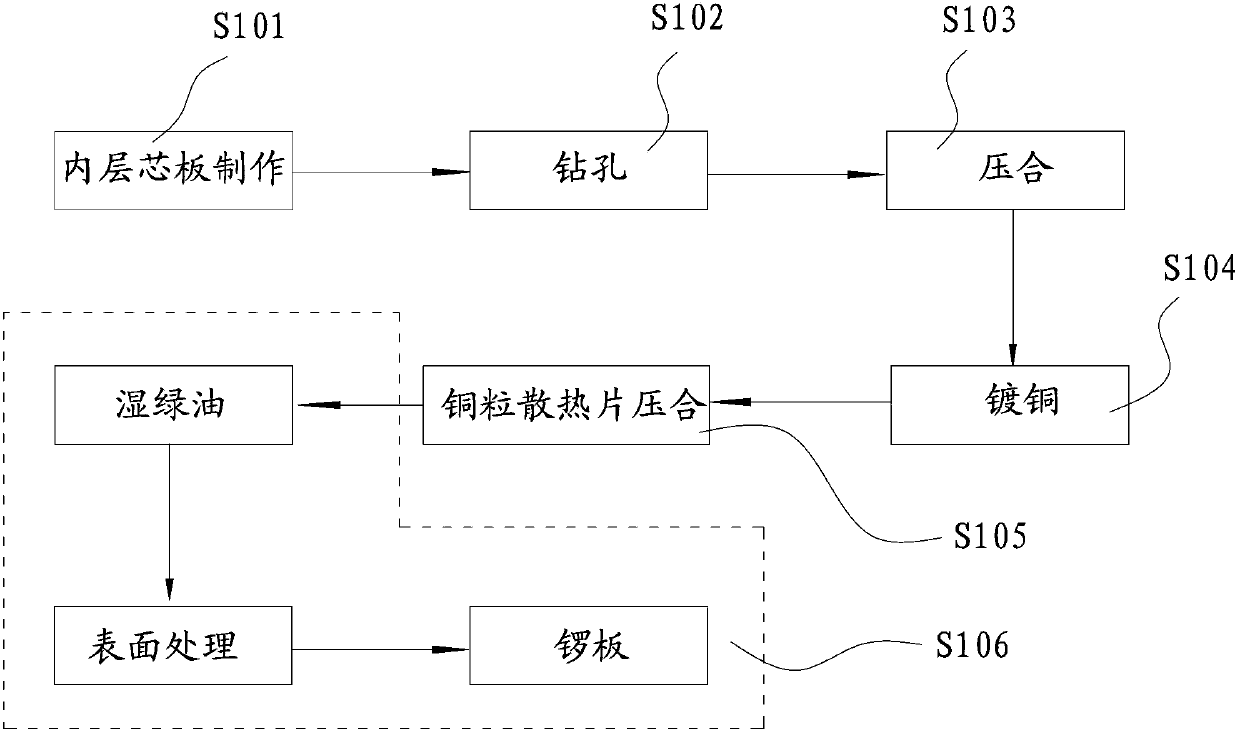

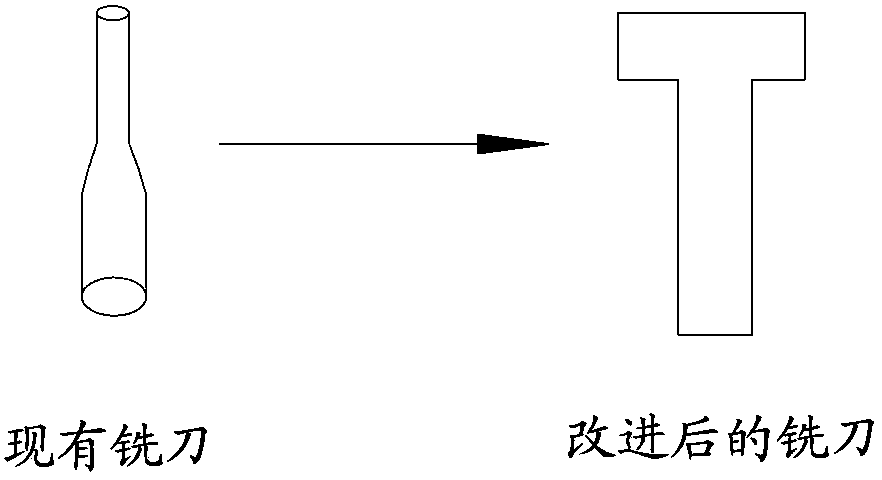

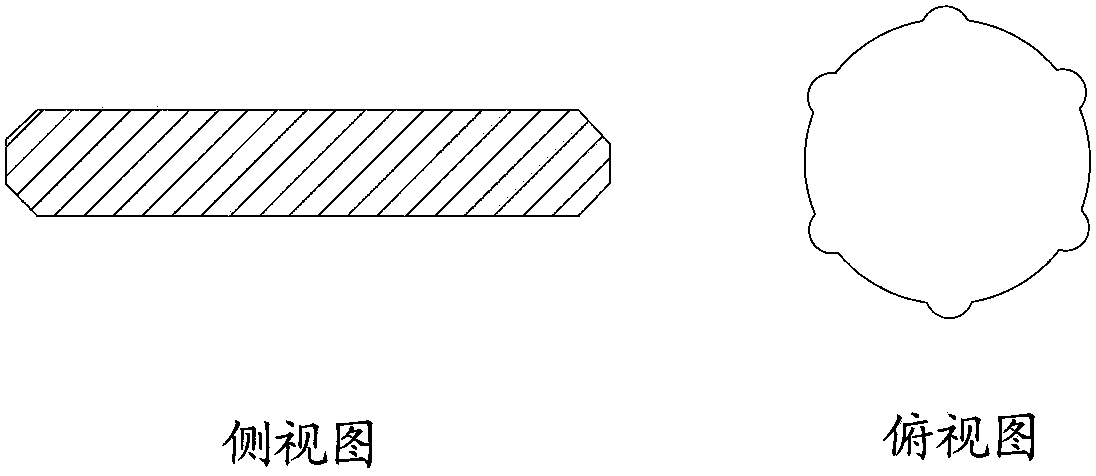

[0025] Take copper heat sinks with diameters of 8.2±0.005mm and 10.2±0.005mm embedded on a 1.7mm thick PCB as an example. figure 1 It is a complete circuit board manufacturing process flow adopted in this embodiment. figure 2 It is a comparison diagram of milling cutter structure before and after improvement in the embodiment of the present invention. image 3 It is a schematic diagram of the structure of the copper heat sink embedded in the circuit board in the embodiment of the present invention, and the diameter of the copper heat sink can be between 8mm-12mm. The diameters of the copper cooling fins used in this embodiment are 8.2±0.005mm and 10.2±0.005mm.

[0026] The following combination figure 1 , describe the embodiment of the present invention in detail, wherein the production of the inner layer core board, wet green oil, and surface treatment are traditional processes. Here, only a brief overview of the method used in this example is given, but it is not limited ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com