Driving system for railroad vehicle

一种驱动系统、铁路车辆的技术,应用在铁路车辆、电力制动系统、车辆储能等方向,能够解决重新进行供油设施等问题,达到机动性高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

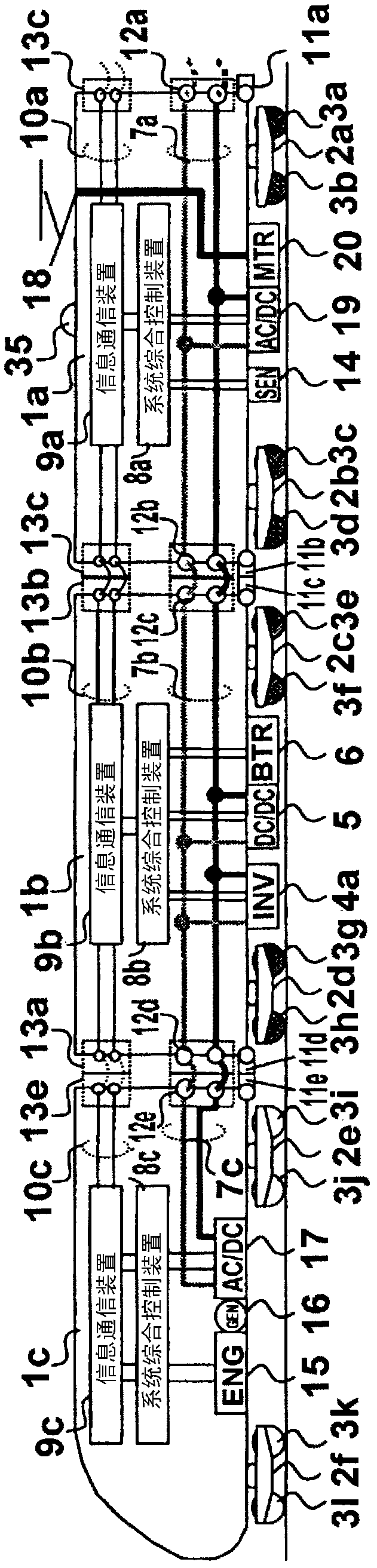

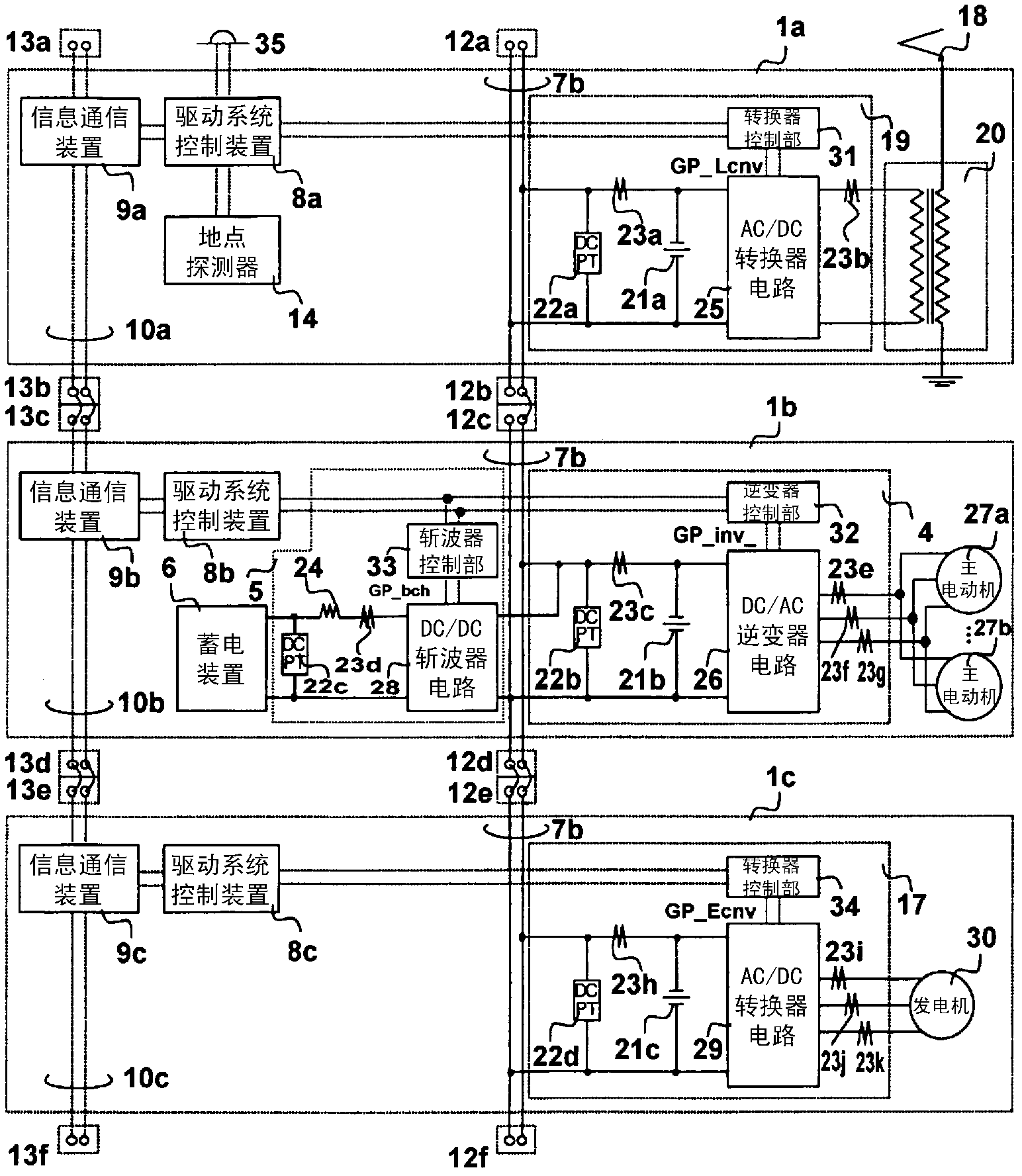

[0031] figure 1 It is a figure which shows the device structure of one Embodiment in the drive system of the railway vehicle of this invention.

[0032] Vehicles 1a, 1b, and 1c are partial vehicles constituting a train formation. The third vehicle 1a is equipped with workshop connectors 11a, 11b, the second vehicle 1b is equipped with workshop connectors 11c, 11d, the first vehicle 1c is equipped with workshop connectors 11e, 11f, and vehicle 1a and vehicle 1b are connected to the workshop through the workshop connector 11b. Connector 11c, vehicle 1b and vehicle 1c are connected through workshop connector 11d and workshop connector 11e.

[0033]The vehicle 1a is supported on an unillustrated track surface via a bogie 2a via axles 3a, 3b, and via a bogie 2b via axles 3c, 3d. The vehicle 1b is supported on an unillustrated predetermined surface by passing through axles 3e, 3f via a steering cart 2c, and via axles 3g, 3h via a steering cart 2d. The vehicle 1c is supported on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com