Thin film alloy electrodes

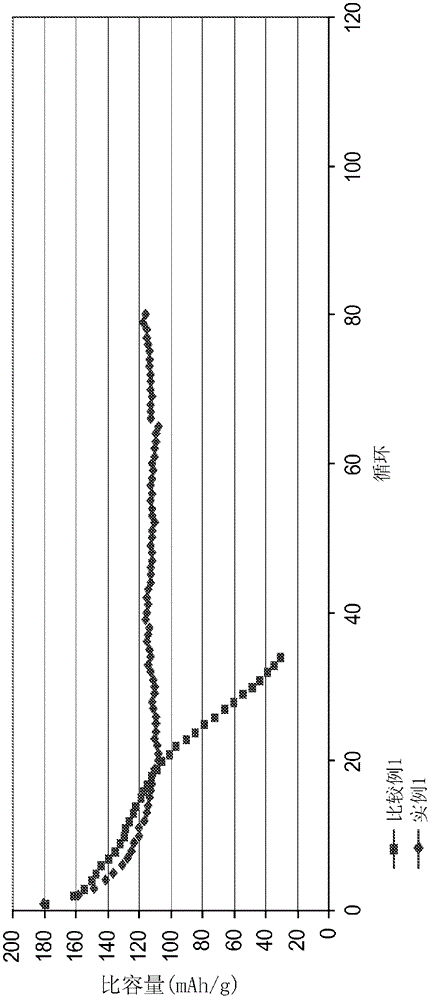

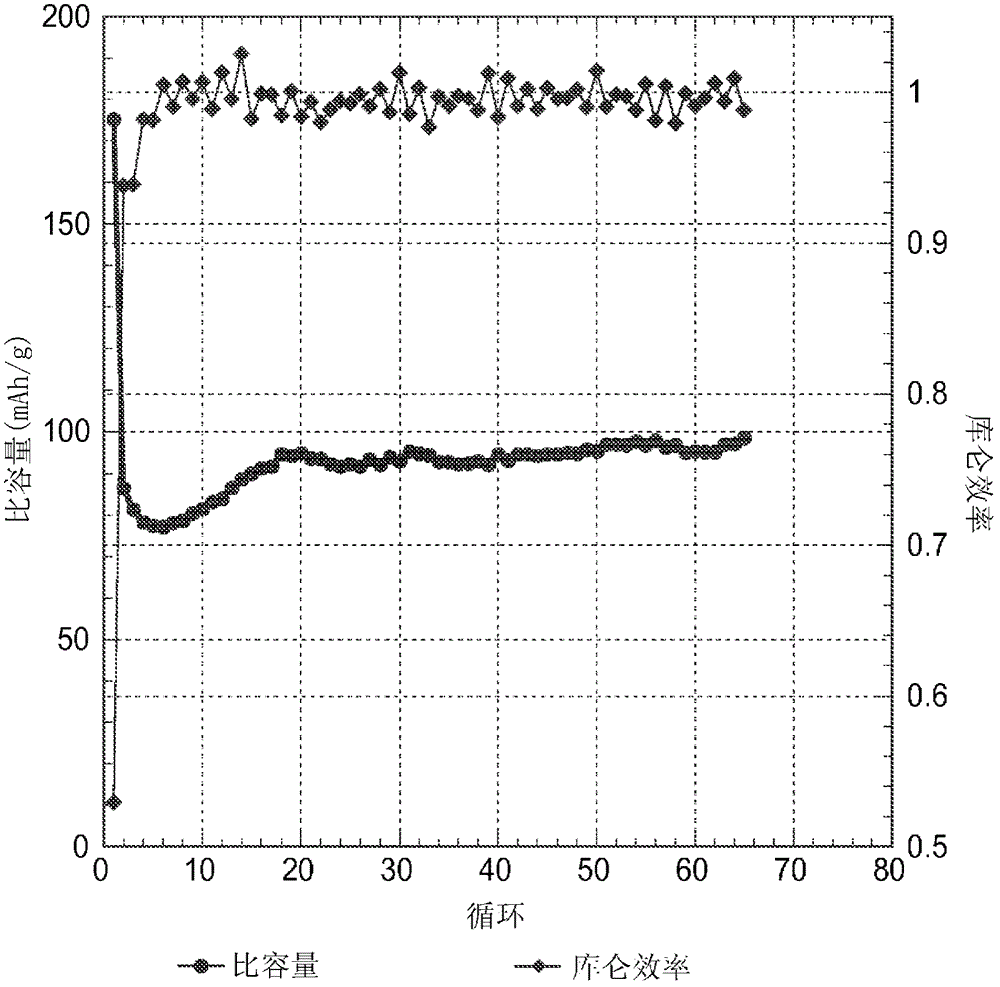

A technology of thin film electrodes and mixed metals, applied in battery electrodes, electrode carriers/current collectors, circuits, etc., can solve the problems of lithium insertion/deintercalation reversibility deterioration, conductivity loss, etc., and achieve high energy density and high thermal stability performance and long cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0045] The preparation of the alloy melt and the performance of the battery are described below.

[0046] Example 1-Al 99 In 1 foil electrode

[0047] 20 g (0.74 moles) of 99.99% pure aluminum pellets (Alfa Aesar) were placed in a 50 ml porcelain crucible and placed in a 750°C furnace. After about 20 minutes, 0.86 g (0.0075 mole) of 99.99% pure indium was added to the molten aluminum at 750°C. The crucible and its contents were kept at 750°C for an additional 20 minutes, shaking periodically to stir the molten metal. After a total of 40 minutes the crucible contents were poured into a copper dish mold and allowed to cool to room temperature. A small piece of the hardened melt is next cut from the ingot and rolled into foil by a mechanical, manually operated rolling mill. The final thickness of the foil is between 50 μm and 100 μm.

[0048] A 2325 coin cell was constructed to test the performance of the alloy foil as a battery electrode. The negative pole is 2c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com