Catalyst for aqueous-phase preparation of indole nitrogen arylide and preparation method of indole nitrogen arylide

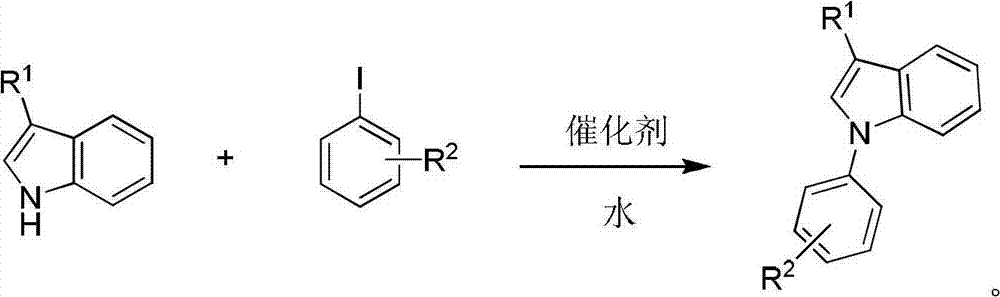

A technology for the preparation of indole nitrogen aromatics and water phases, applied in the direction of physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, chemical instruments and methods, etc., can solve the problem of no catalyst, no water phase synthesis method and other problems, to achieve the effect of simple composition, easy control of reaction conditions and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Cuprous iodide (8 mg, 0.04 mmol), 2,2'-bipyridine (12 mg, 0.08 mmol), betaine (94 mg, 0.8 mmol), tripotassium phosphate (170 mg, 0.8 mol), indole (47 mg, 0.4 mmol), and p-methoxyiodobenzene (187 mg, 0.8 mmol) were placed in a reaction flask, 2 ml of water were added, heated to 90 degrees Celsius, and reacted for 10 hours. Chloroform was added to the reaction system, the product was extracted with chloroform, concentrated and separated by silica gel chromatography to obtain 72 mg of indole nitrogen-p-methoxybenzene with a yield of 81%.

[0033] NMR data of indole nitrogen p-methoxybenzene: 1 H NMR (500MHz, CDCl 3 )δ7.67(d, J=8.0Hz, 1H), 7.45(d, J=8.0Hz, 1H), 7.40(d, J=9.0Hz, 2H), 7.27(d, J=3.5, 1H), 7.20(t, J=8.0, 1H), 7.14(t, J=8.0, 1H), 7.02(d, J=9.0, 2H), 6.64(d, J=3.5, 1H), 3.87(s, 3H) .

Embodiment 2

[0035] Cuprous iodide (8 mg, 0.04 mmol), 2,2'-bipyridine (12 mg, 0.08 mmol), betaine (94 mg, 0.8 mmol), tripotassium phosphate (170 mg, 0.8 mol), indole (47 mg, 0.4 mmol), and p-nitroiodobenzene (199 mg, 0.8 mmol) were placed in a reaction flask, 2 ml of water were added, heated to 90 degrees Celsius, and reacted for 10 hours. Chloroform was added to the reaction system, the product was extracted with chloroform, concentrated and separated by silica gel chromatography to obtain 90 mg of indole nitrogen-p-nitrobenzene with a yield of 95%.

[0036] NMR data of indole nitrogen p-nitrobenzene: 1 H NMR (500MHz, CDCl 3 )δ8.42-8.37(m, 2H), 7.72-7.64(m, 4H), 7.37(d, J=3.5Hz, 1H), 7.32-7.21(m, 2H), 6.76(d, J=3.5Hz , 1H).

Embodiment 3

[0038] Cuprous iodide (8 mg, 0.04 mmol), 2,2'-bipyridine (12 mg, 0.08 mmol), betaine (94 mg, 0.8 mmol), tripotassium phosphate (170 mg, 0.8 mol), indole (47 mg, 0.4 mmol), and p-chloroiodobenzene (191 mg, 0.8 mmol) were placed in a reaction flask, 2 ml of water were added, heated to 90 degrees Celsius, and reacted for 10 hours. Chloroform was added to the reaction system, the product was extracted with chloroform, concentrated and separated by silica gel chromatography to obtain 74 mg of indole nitrogen p-chlorobenzene with a yield of 82%.

[0039] NMR data of indole nitrogen p-chlorobenzene: 1 H NMR (500MHz, CDCl 3 )δ7.68(d, J=8.0Hz, 1H), 7.52-7.41(m, 5H), 7.28(d, J=3.0Hz, 1H), 7.25-7.15(m, 2H), 6.68(d, J =3.0Hz, 1H).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com