Four-wheel drive tractor

A four-wheel drive, tractor technology, applied in the direction of gear transmission, steering mechanism, mechanical equipment, etc., can solve the problems such as the inability to use the folded steering mechanism, the loose structure of large tractors, the increase of the rotation radius, etc., to achieve compact layout and volume. Small, volume-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

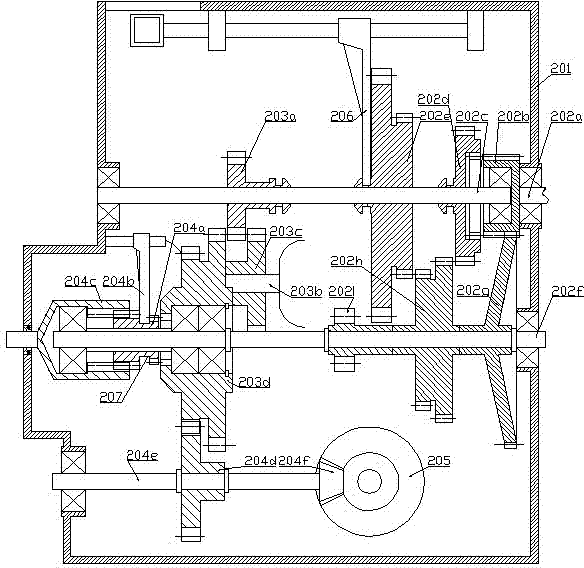

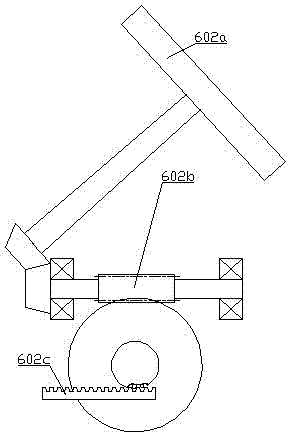

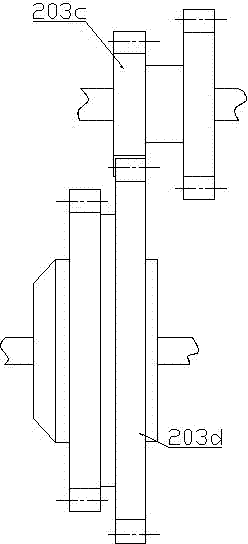

[0025]As shown in the figure, the four-wheel drive tractor includes a front frame 5 and a rear frame 8, and a folding steering mechanism 6 is arranged between the front frame 5 and the rear frame 8. The waist steering mechanism 6 is composed of a waist steering knuckle 601 and a control system 602. The control system 602 includes a steering wheel 602a, a power transmission device 602b connected to the steering wheel 602a, and a drive device 602c connected to the power transmission device 602b. In an example, the power transmission device 602b is composed of a set of bevel gears and a set of worm gears, and the worm gear of the power transmission device 602b is connected with a driving device 602c to realize the kink between the front frame 5 and the rear frame 8, In this embodiment, the driving device 602c is a rack and pinion driving device, wherein one end of the rack is hinged to the front frame 5 . A power source 1 and a first gearbox 2 connected to the power source 1 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com