Polyacrylamide-based dry paper-strengthening agent, and paper manufacturing method

A technology of polyacrylamide and polyacrylamide, which is applied in the field of polyacrylamide-based internal paper strength agent and papermaking, and the field of polyacrylamide-based paper-strength agent, which can solve problems such as good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] 547.80 g of water, 201.70 g of a 50% aqueous acrylamide solution as monomers (1), dimethylaminoethyl methacrylate, and 12.26 g of ester, 5.07 g of itaconic acid, 1.16 g of N,N-dimethylacrylamide, and 1.97 g of sodium methallylsulfonate were adjusted to pH 3.0 with 12.02 g of 30% sulfuric acid aqueous solution. Next, the temperature was raised to 60°C under a nitrogen atmosphere, and 0.24 g of an aqueous solution of ammonium persulfate was added as a polymerization initiator to initiate polymerization, and the reaction temperature was raised to 90°C. Thereafter, 49.20 g of water, 8.60 g of 30% sulfuric acid aqueous solution, 136.68 g of 50% acrylamide aqueous solution, 8.17 g of dimethylaminoethyl methacrylate, 1.69 g of itaconic acid, and N,N-dimethylacrylic acid were added. Add 0.48 g of persulfuric acid to the monomer (2) composed of 0.77 g of amide and 0.90 g of sodium methallyl sulfonate. When the estimated viscosity at 25° C. reaches 3000 mPa·s, add 49.45 g of wate...

Embodiment 2~9、 comparative example 1~7

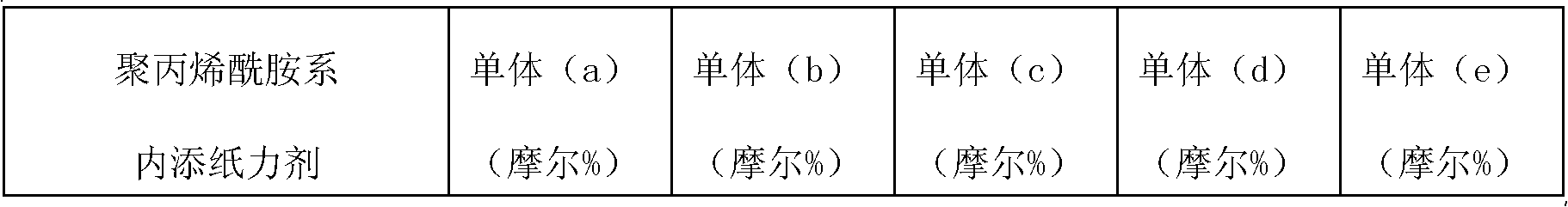

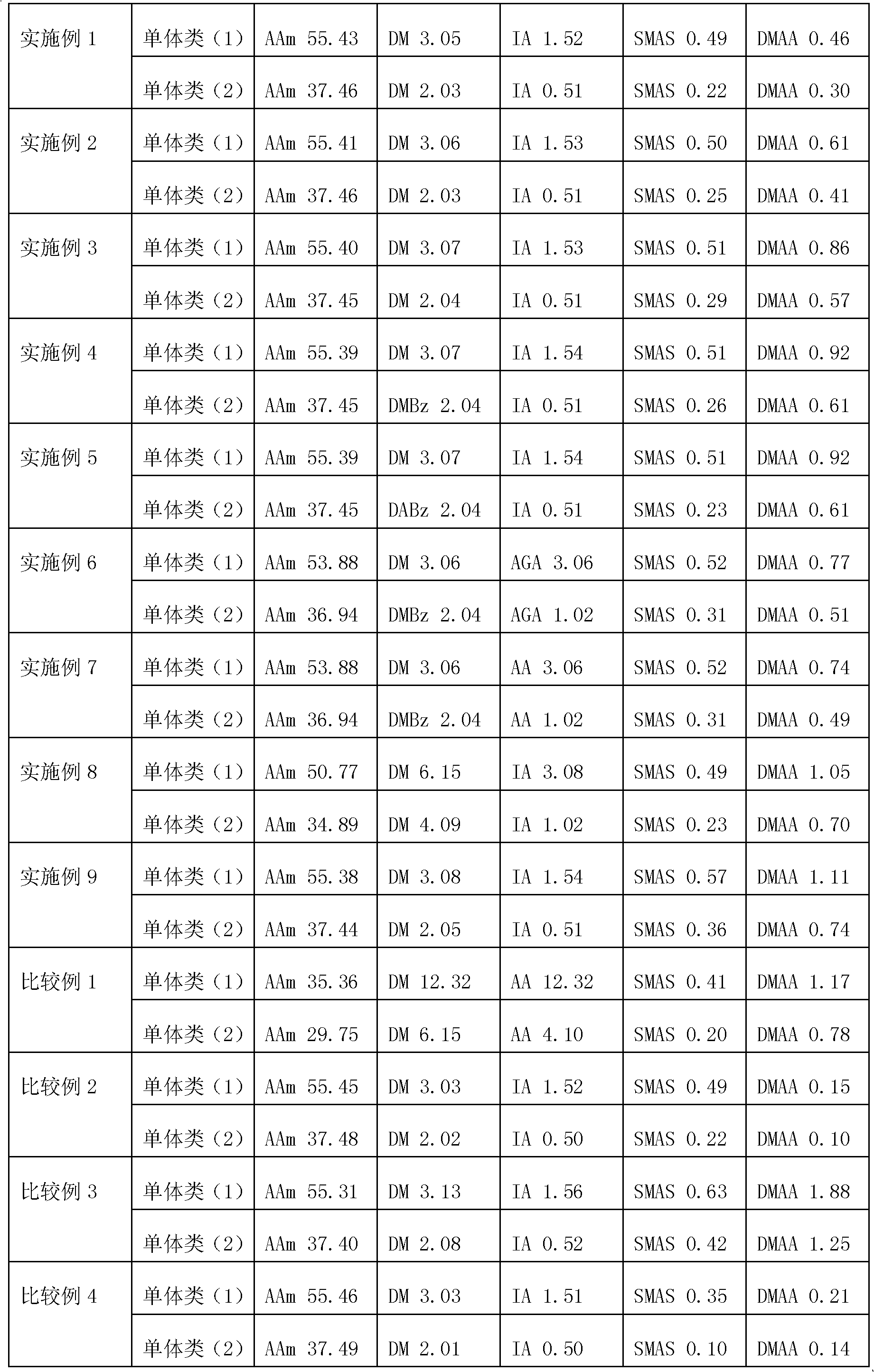

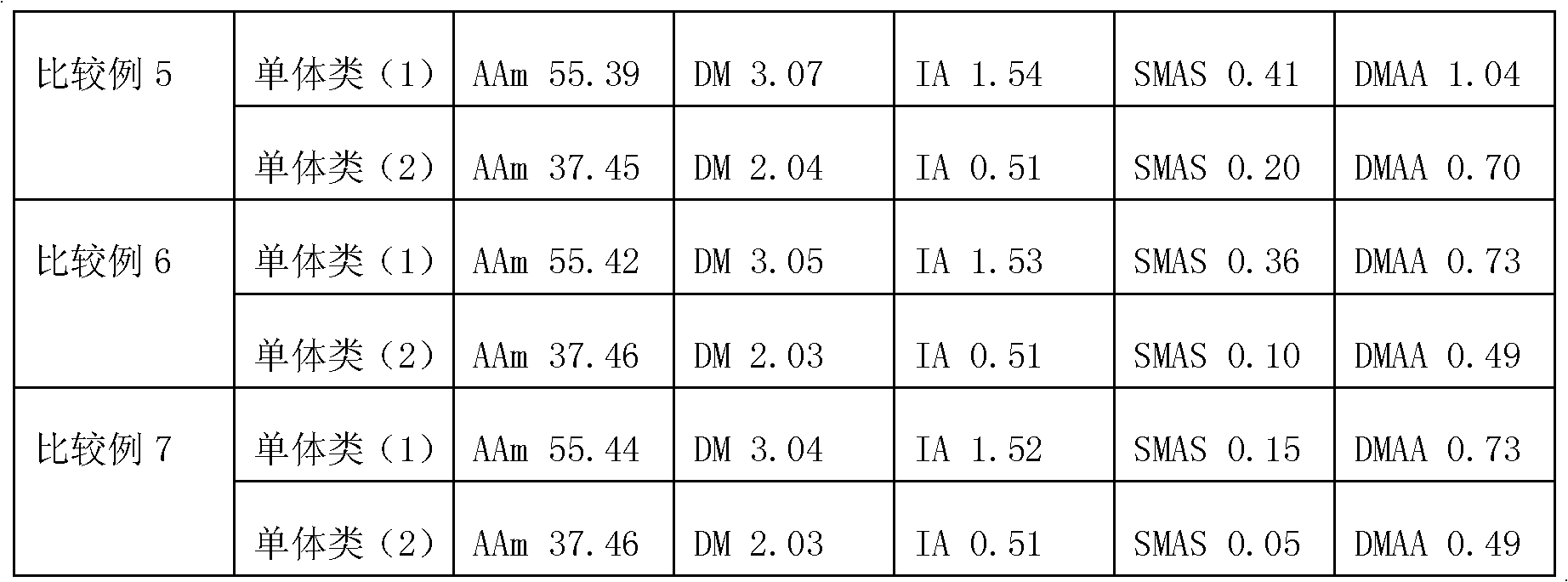

[0078] In addition to changing the composition of monomers (1) and monomers (2) as shown in Table 1, and changing the viscosity of the paper strength agent in the polyacrylamide system as shown in Table 2, and Example 1 Carry out likewise, obtained polyacrylamide system internal paper strength agent. As in Example 1, the obtained polyacrylamide-based internal paper strength agent was adjusted to a solid content of 20.0%, pH 3.0, and the stringiness, viscosity (25°C), and weight-average molecular weight were measured. Table 2 shows the ratio of the calculated weight-average molecular weight to the viscosity.

[0079] Table 1

[0080]

[0081]

[0082]

[0083] The abbreviations in Table 1 correspond to the following substances.

[0084] AAm: acrylamide

[0085] M: Dimethylaminoethyl methacrylate

[0086] DMBz: Dimethylaminoethyl Methacrylate Benzyl Ammonium Chloride Quaternary Ammonium Chloride

[0087] DABz: Dimethylaminoethyl Acrylate Benzyl Chloride Quaternary ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com