Connecting structure and connecting method for tapered interface and plastic connector of air inlet pipe of air filter

A connection structure and connection method technology, which is applied in the direction of combustion air/combustion-air treatment, charging system, machine/engine, etc. Low tensile strength and other problems to achieve the effect of improving product quality, ensuring customer reputation, and high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The connection structure and connection method of the taper interface of the air filter intake pipe and the plastic joint of the present invention will be described in detail below with reference to the embodiments and the accompanying drawings.

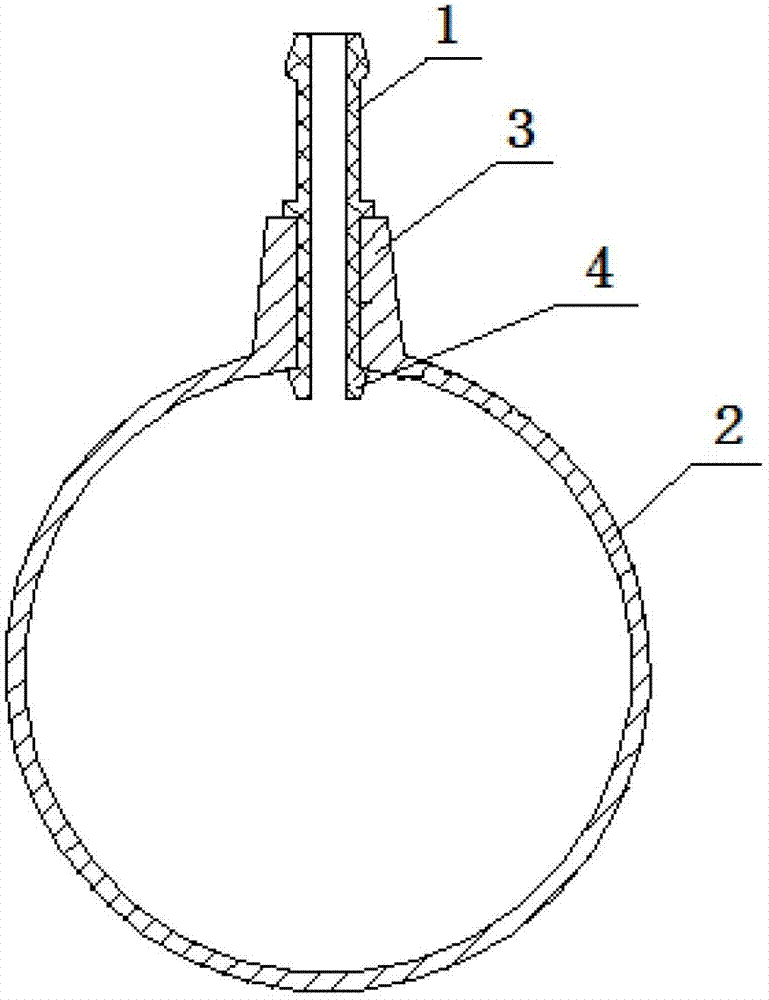

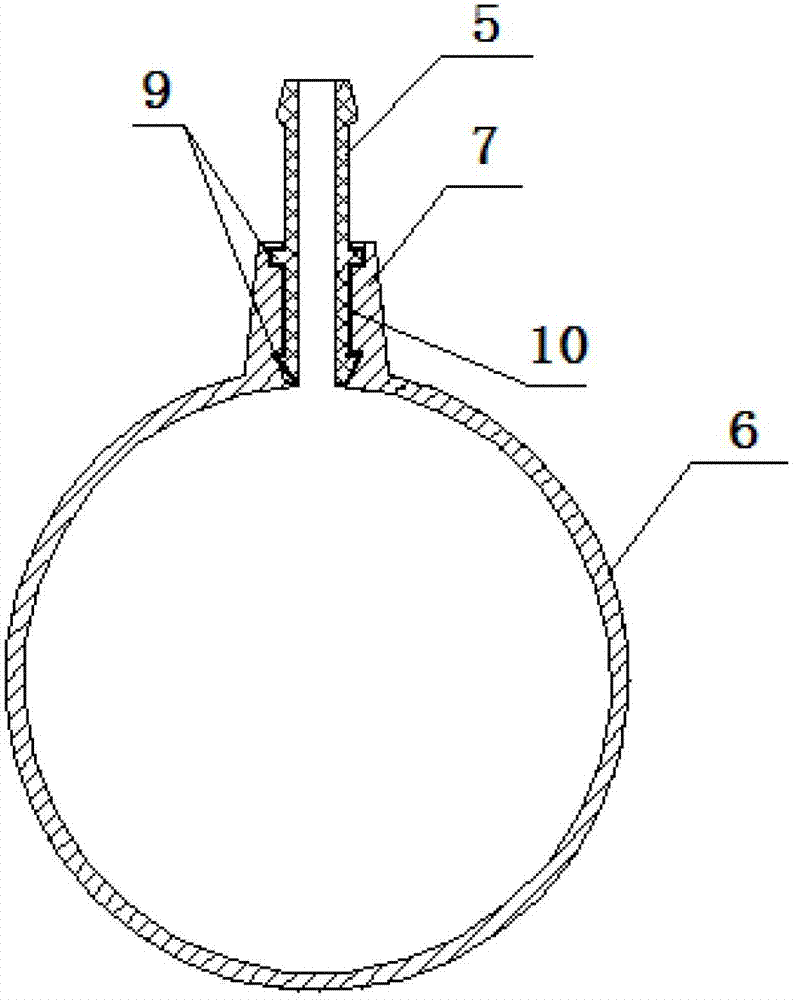

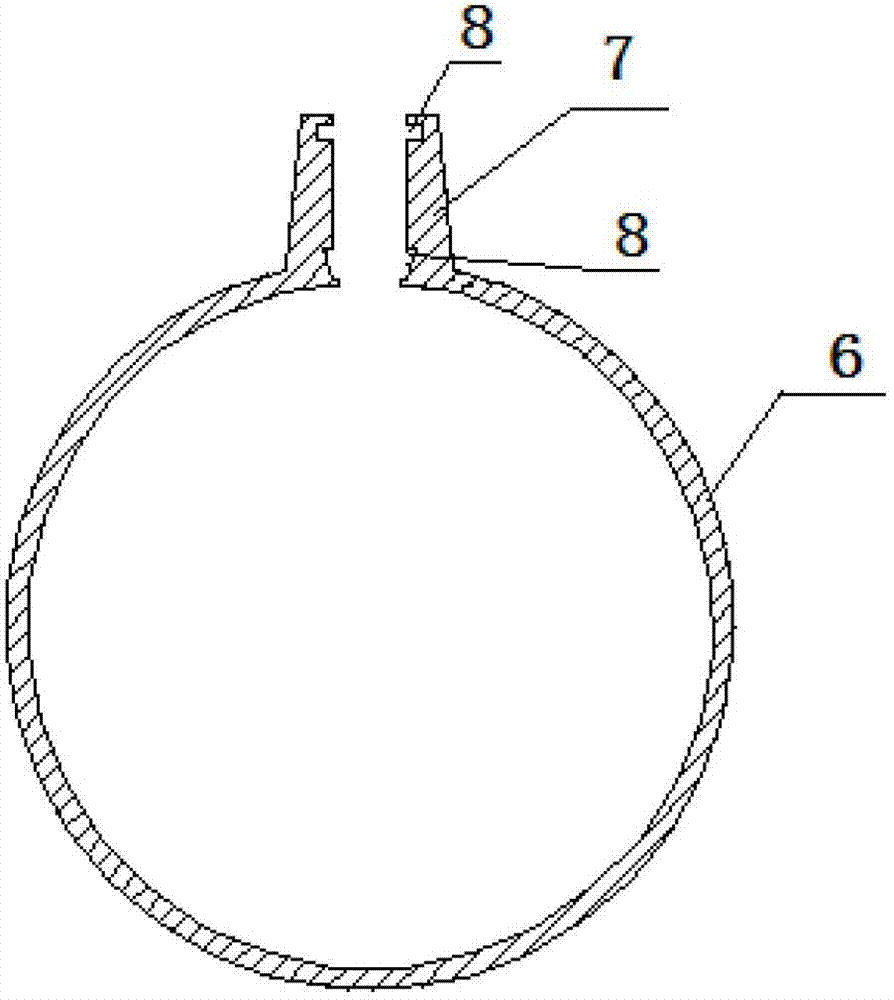

[0037] Such as figure 2 , image 3 , Figure 4 As shown, the connection structure between the air filter intake pipe taper interface and the plastic joint of the present invention includes a tubular plastic joint 5 and an air filter intake pipe 6, and the plastic joint 5 is fixedly connected to the wall formed on the air filter intake pipe 6 In the taper interface 7 on the top, and communicated with the air filter intake pipe 6, it is characterized in that a circle of inward recesses is formed on the inner peripheral wall of the taper interface 7 adjacent to the upper port and the lower port. groove 8, the outer circumference of the plastic connector 5 is respectively formed with two rings of outwardly protruding protrusion...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com