Flexible LCD and manufacturing method thereof

A technology of flexible liquid crystal and a manufacturing method, applied in the field of flexible liquid crystal displays, can solve the problems of fragility and inflexibility of LCD, and achieve the effects of accurate size, simple method and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

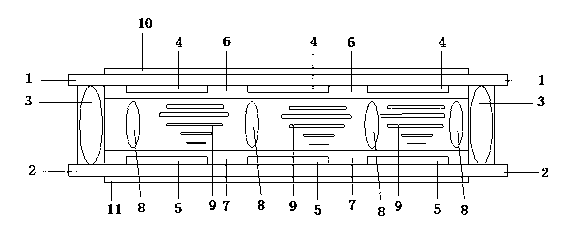

[0043] see figure 1 , the present invention proposes a flexible liquid crystal display (F-LCD for short), which includes: upper flexible plastic substrate 1, lower flexible plastic substrate 2, frame glue 3, upper ITO (Indium Tin Oxides, nano indium tin Metal oxide) electrode 4, lower ITO (Indium Tin Oxides, nanometer indium tin metal oxide) electrode 5, upper PI (Polyimide, polyimide) alignment film 6, lower PI (Polyimide, polyimide) alignment film 7. Multiple spacer balls 8, liquid crystal 9, upper polarizer 10, lower polarizer 11.

[0044] The upper flexible plastic substrate 1 is arranged in parallel above the lower flexible plastic substrate 2 .

[0045] Both the upper flexible plastic substrate 1 and the lower flexible plastic substrate 2 are made of PC (Polycarbonate) conductive film.

[0046] Since flexible materials are used, the upper flexible plastic substrate 1 and the lower flexible plastic substrate 2 can be bent and are not easily broken.

[0047] The frame g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com