Phase Locked Loop (PLL) With Analog And Digital Feedback Controls

A control loop and circuit technology, applied in the direction of automatic power control, electrical components, etc., can solve a lot of problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

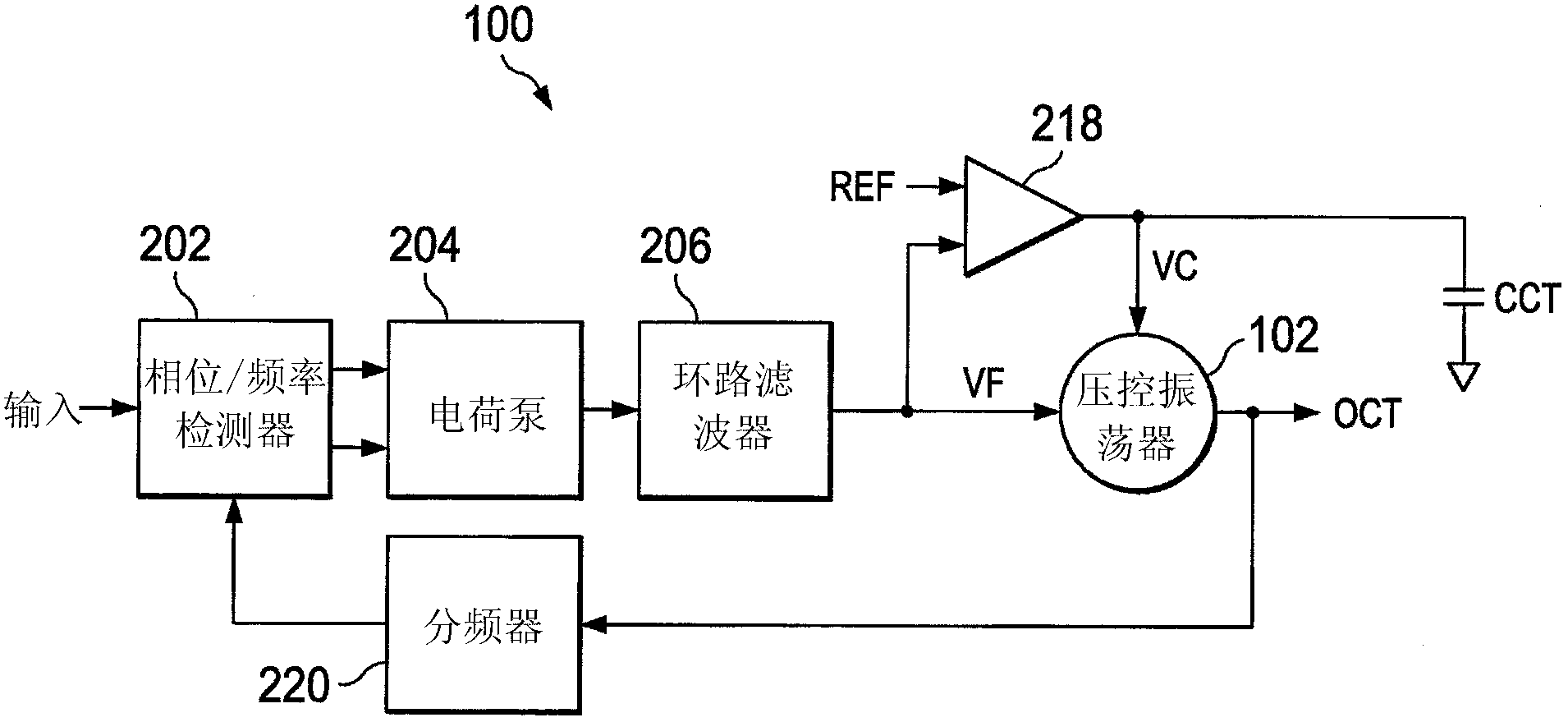

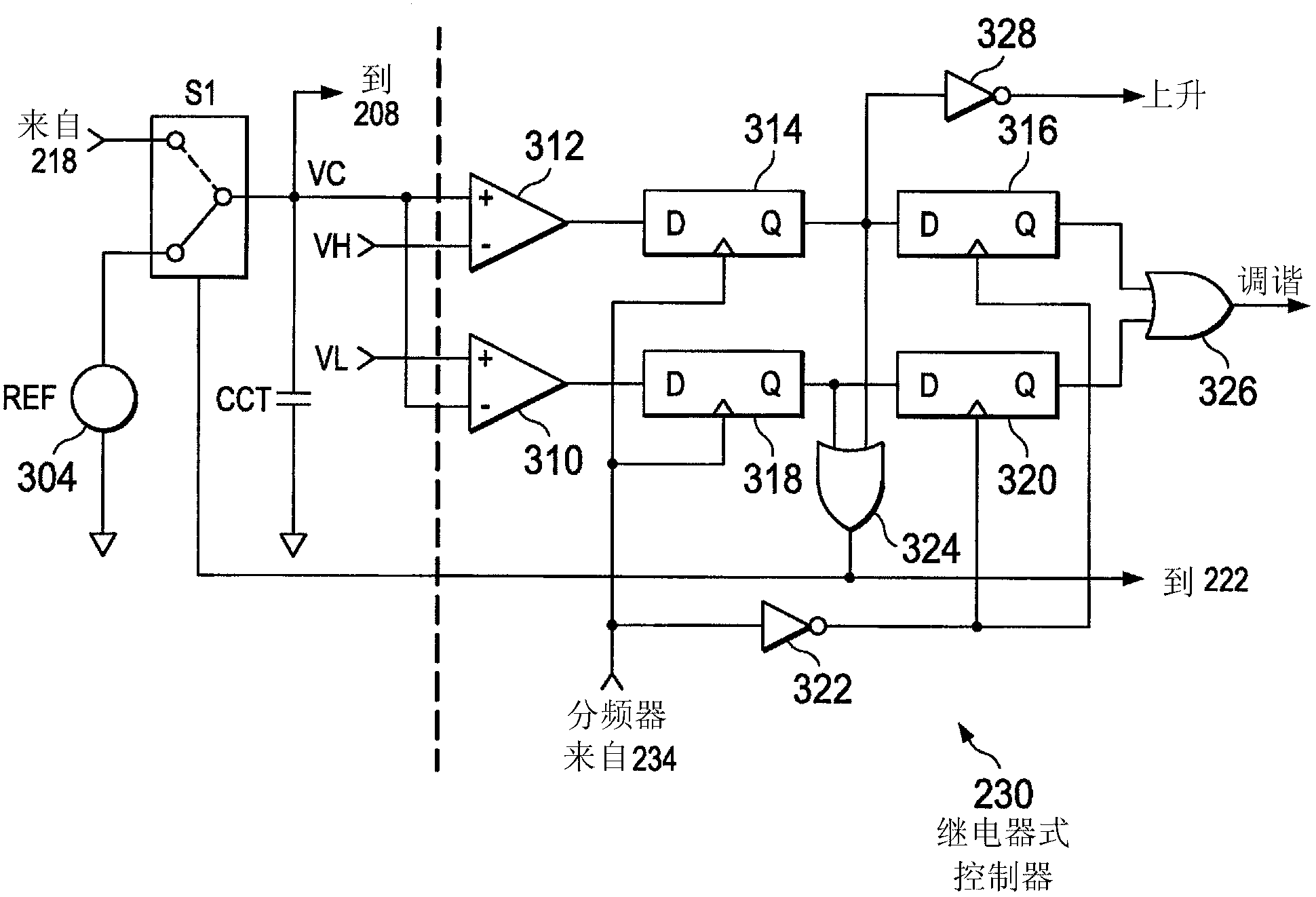

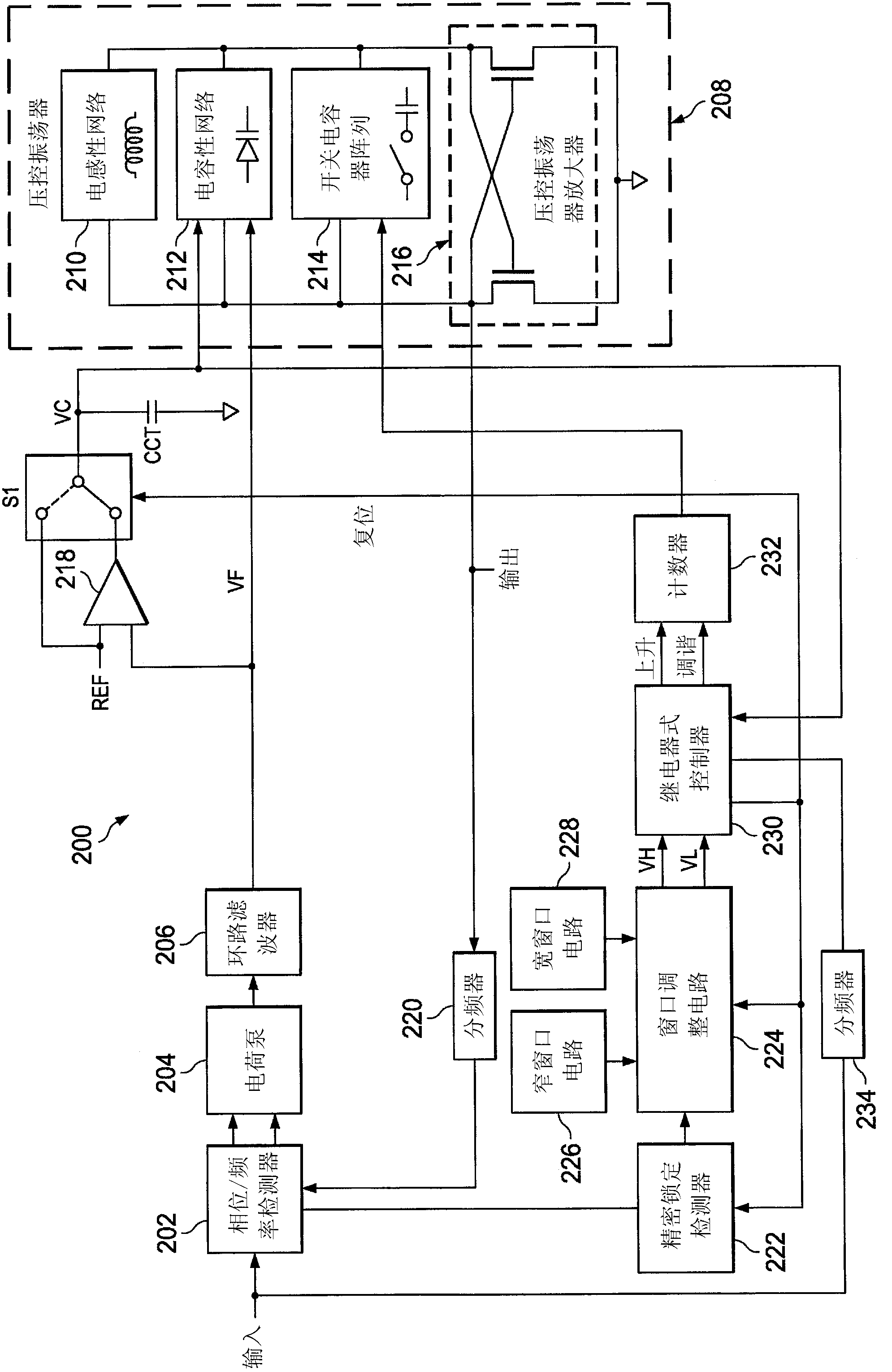

[0022] figure 2 , reference numeral 200 generally designates a PLL according to an example embodiment of the invention. PLL 200 generally consists of PFD 202, charge pump 204, loop filter 206, VCO 208, amplifier 218, switch S1, frequency divider 220, and a control loop. VCO 208 generally consists of inductive network 210 , capacitive network 212 , switched capacitor array 214 and VCO amplifier 216 . The control loop generally consists of precision lock detector 222 , narrow window circuit 226 , wide window circuit 228 , window adjustment circuit 224 , relay controller 230 , counter 232 and frequency divider 234 .

[0023] In general, PFD 202 , charge pump 204 , loop filter 206 , VCO 208 , and frequency divider 220 operate as a high bandwidth loop to generate output signal OUT from an input signal, similar to the high bandwidth loop of PLL 100 . PFD 202 compares the feedback signal from frequency divider 220 with input signal IN to generate rising and falling signals for char...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com