Method for manufacturing large and thick rare precious metal explosion-clad steel plate

A technology for rare and precious metals and clad steel plates, which is used in manufacturing tools, metal layered products, metal processing equipment, etc. It can solve the problems of large uncombined area at the initiation point, large explosion welding manufacturing area, and reduced design margins. The effect of small uncompounded area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

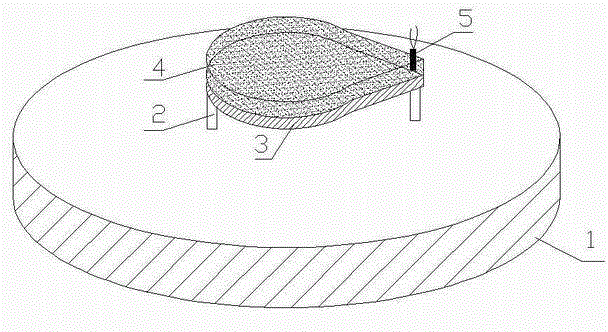

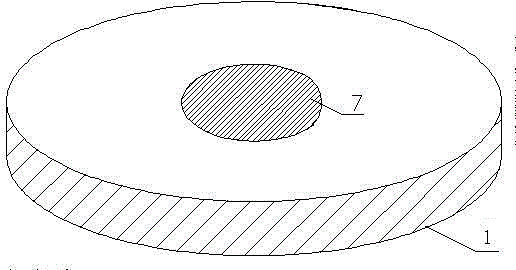

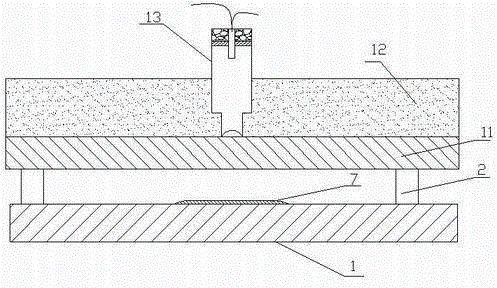

[0028] Manufacture a zirconium-steel composite material with a large area and a thick layer. The grade of the layered zirconium plate is R60702. The size is: 3350mm in diameter and 12mm in thickness. First, the zirconium plate with a thickness of 2 mm and a diameter of 100 mm with peach corners is bonded to the central area of the substrate with a diameter of 3500 mm and a thickness of 60 mm through explosive welding; the uncomposited area is removed, and the surrounding area is ground to make a smooth transition; then the first explosive welding is obtained. The zirconium-steel composite material with a 2mm zirconium layer and the titanium-zirconium plate with a cladding diameter of 3500mm and a thickness of 8mm are used for the second explosion welding of the detonation point in the center through a strong detonation device; the area of the uncomposited area of the detonation point does not exceed 15mm The uncomposited area is excavated and ground to the 2mm zirconium l...

Embodiment 2

[0030] Manufacture a titanium-steel composite material with a large area and a thick layer. The grade of the layered titanium plate is TA2, and the size is: 20×2500×8500mm. The base layer is Q235B, and the size is: 60×2500×7500mm. First, the titanium plate with a thickness of 3 mm and a diameter of 100 mm with peach corners is bonded to the central area of the substrate with a diameter of 3500 mm and a thickness of 60 mm through explosive welding; The titanium-steel composite material with a 3mm titanium layer and the titanium plate with a cladding size of 70×2500×8500mm are used for the second explosion welding with the detonation point in the center through a strong detonation device; the uncombined area of the detonation point is controlled at a diameter of 20mm Excavate and grind the non-composite area within the area to the 3mm titanium layer interface obtained by the first explosive welding to perform welding repairs of the same titanium material, and the resulting ti...

Embodiment 3

[0032] Manufacture a titanium-steel composite material with a large area and a thick layer. The grade of the layered titanium plate is TA10, the size is: diameter 4000mm, thickness 18mm, the base layer is 20# (Ⅲ), the size is: diameter 4000mm, thickness 60mm. First, the titanium plate with a thickness of 2 mm and a diameter of 80 mm with peach corners is bonded to the central area of the substrate with a diameter of 3500 mm and a thickness of 60 mm through explosive welding; the uncomposited area is removed, and the surrounding area is ground to make a smooth transition; The titanium-steel composite material with a titanium layer of 2mm and the titanium plate with a diameter of 4000mm and a thickness of 18mm are used for the second explosion welding with the initiation point in the center and through a strong initiation device; the uncombined area of the initiation point is controlled within an area with a diameter of 30mm Excavate and grind the uncomposited area until the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com