Diamond blunt tool

A diamond-aligned technology, which is applied in the field of diamond-aligned tools, can solve the problems of easy core breakage of the processing pen, poor wear resistance of cutting edge materials, and easy cracking of surface paint, so as to achieve stable shape and specification and low scrap rate , the effect of not easy to crack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

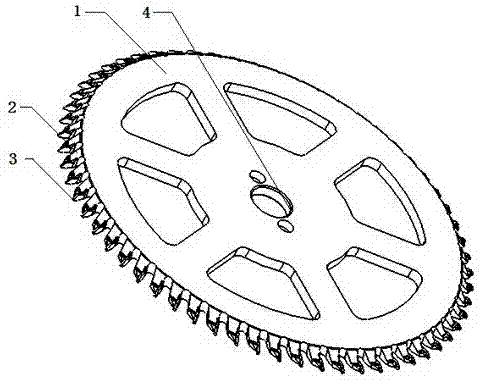

[0017] Such as figure 1 As shown, the tool includes a cutter body 1, which is disc-shaped, and a group of tooth seats 2 integrally formed with it are uniformly arranged on the circumference of the cutter body 1, and each tooth seat 2 is provided with A knife tooth 3, the knife tooth 3 is firmly welded on the tooth seat 2 by adding welding mud and silver at a high temperature of 600-800°C, the knife tooth 3 is made of diamond, and the purpose of using diamond material is In order to improve the service life of the tool. Synthetic diamond material is composed of synthetic polycrystalline diamond material and cemented carbide between 0.3-2.0mm, and the total thickness is between 1.0-6.0mm. It is a particularly wear-resistant and extremely high-hardness material. Single crystal diamond The material is composed of natural diamond material and cemented carbide, which is a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com