Sensing and heating method of high-magnetic induction oriented silicon steel

A technology of high magnetic induction orientation and induction heating, which is applied in the field of steel rolling heating, can solve the problems of low performance stability of finished products, low precision of slab temperature control, and abnormal disturbance, so as to increase investment, production cost and control effect Significant, guaranteed heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

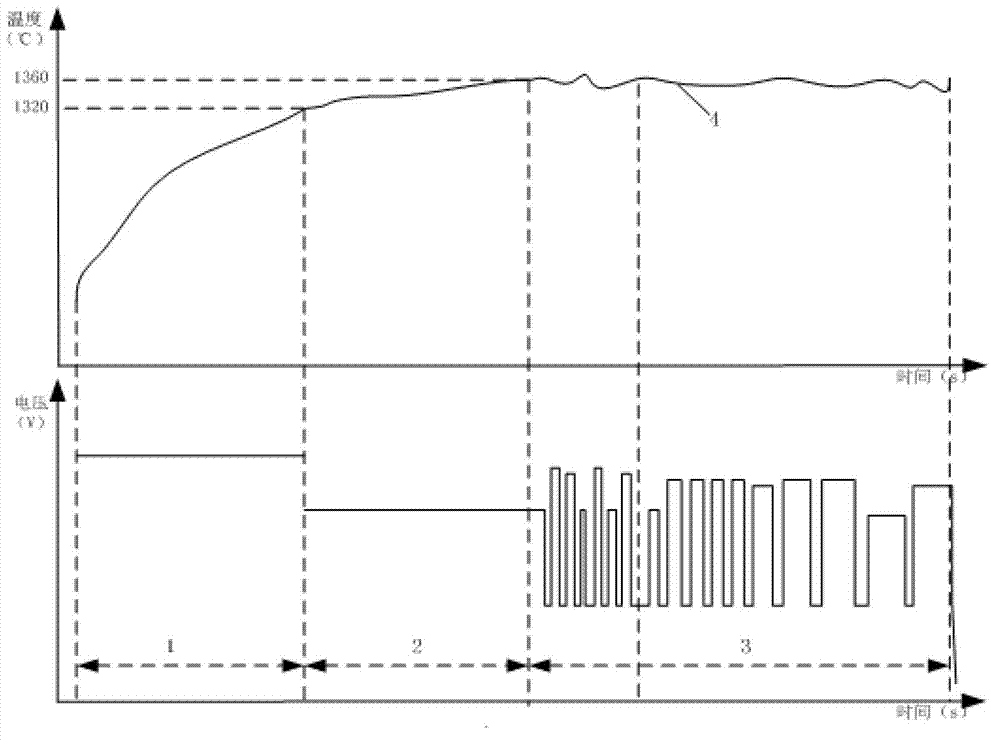

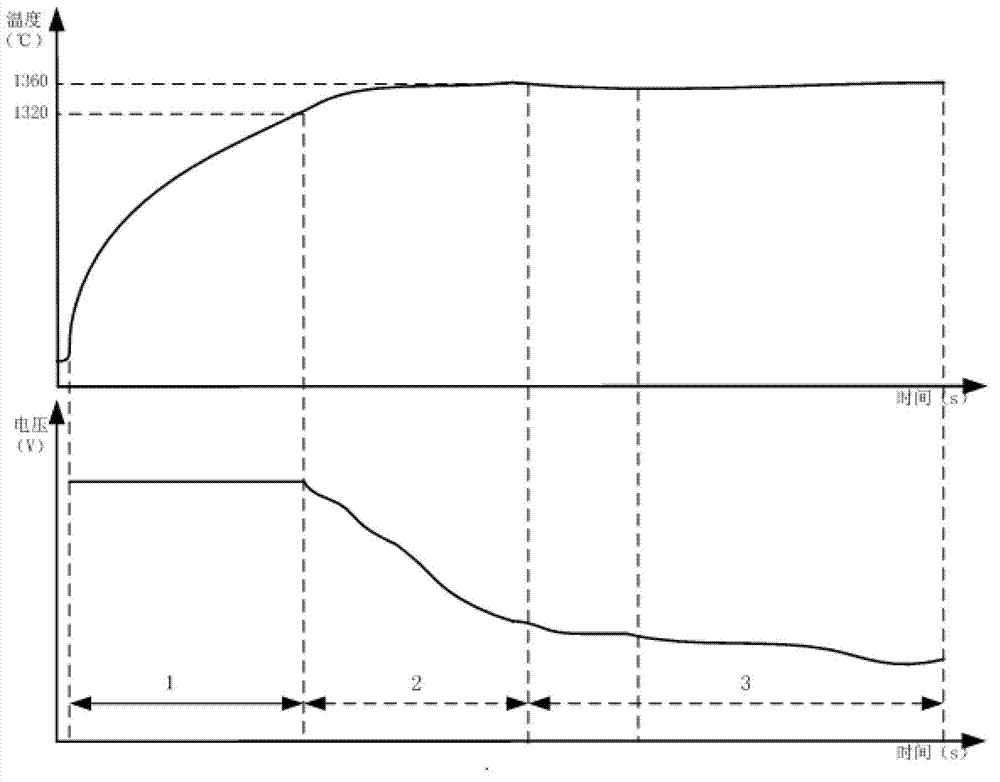

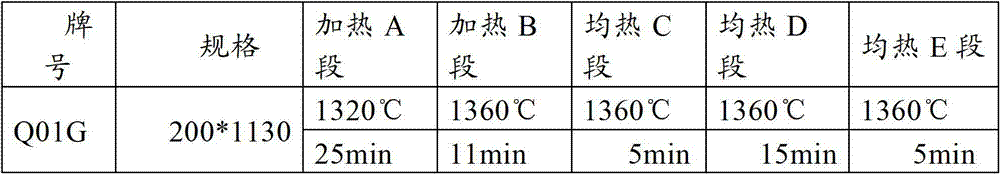

[0027] An induction heating method for high magnetic induction oriented silicon steel provided in the embodiment of the present invention includes the following steps, and the specific parameters are shown in Table 1:

[0028] Table 1 Specific parameters of each heating step

[0029]

[0030] Step A Put the slab of high magnetic induction grain-oriented silicon steel with the brand Q01G and the specification of 200*1130 into the induction heating furnace for heating, and use the inverter to set the basic voltage, wherein, in this embodiment, the basic voltage is 2300V . Then carry out constant voltage rapid temperature rise, the longest heating time is no more than 25min, the slab temperature after heating is 1320°C, wherein, the temperature of the slab entering the furnace is controlled above 900°C, the oxygen content in the furnace is kept below 1000PPM, and the nitrogen in the furnace is kept 2 The ambient positive pressure difference is 3 Pa. The purpose of this is to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com